Hoisting structure with barge used as lifting weight test buoyancy tank

A technology of barges and buoys, applied in the field of hoisting structures, can solve the problems that are not conducive to the sharing of multi-point hoisting points, increase the difficulty of construction, and high risk factors, and achieve the effect of saving materials, saving time, and reducing the number of shackles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

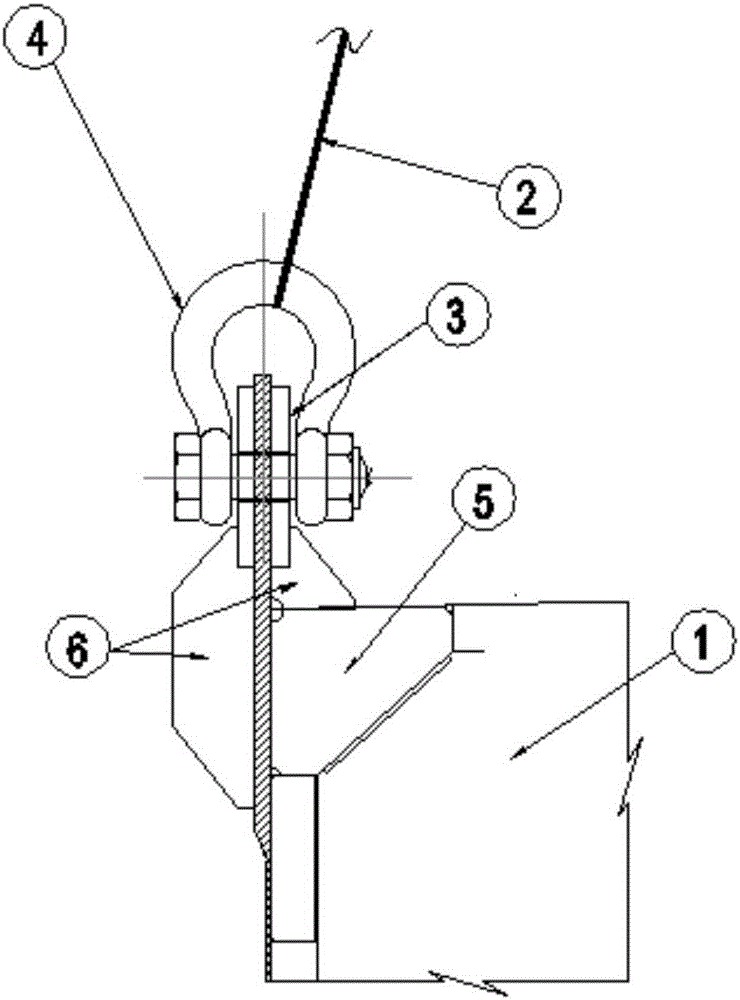

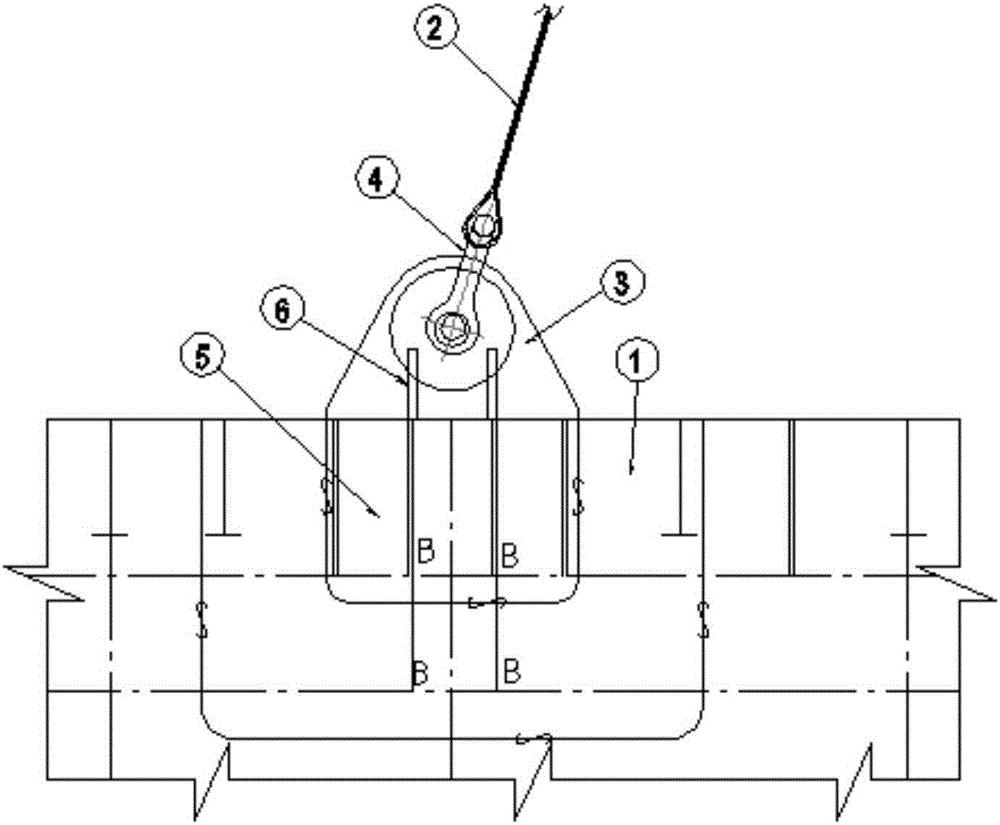

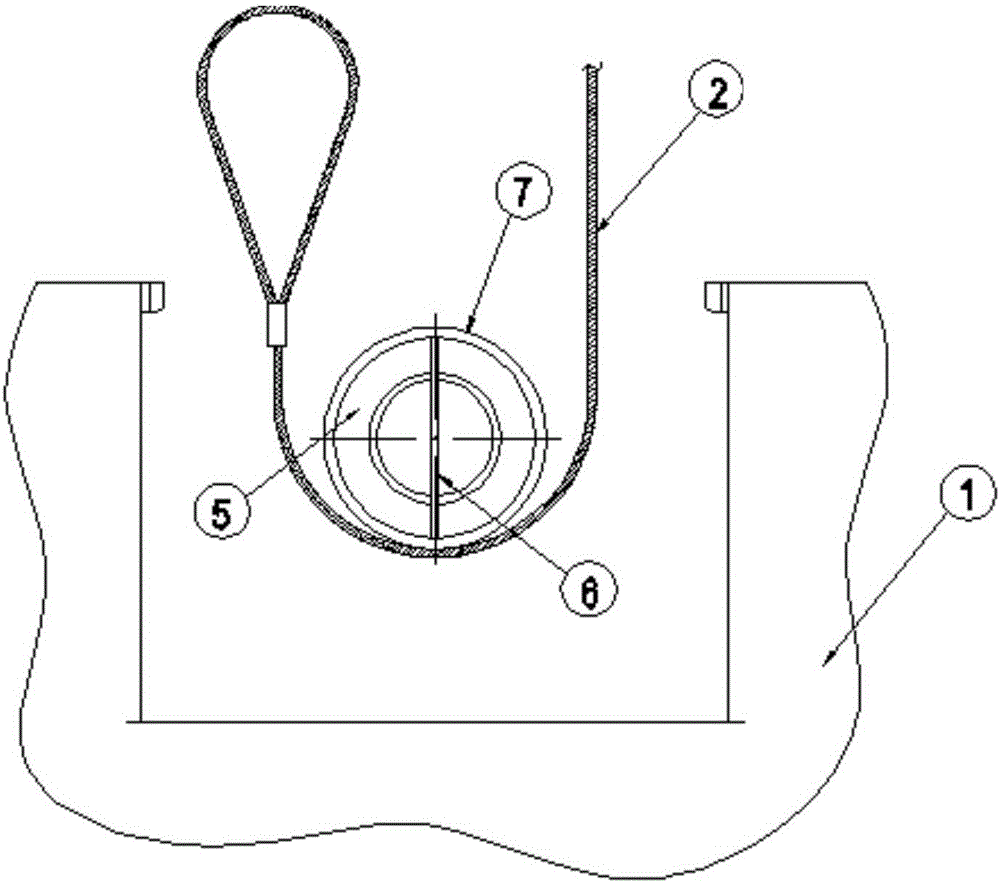

[0029] like image 3 and 4 Shown, be the hoisting structure that adopts barge as the lifting test buoyant box of the present embodiment, comprise barge 1, hoisting wire rope 2, hoisting point steel pipe 7 and cover plate (not shown in the figure), hoisting wire rope 2 bypasses The lifting point steel pipe is hooked on the suspension hook (not shown in the figure) used for the lifting test, and the lifting point steel pipe 2 is located below the main deck of the barge. The number of hanging point steel pipes can be determined according to actual operation needs. The steel pipe 2 for the lifting point is arranged on the main structure of the barge and integrally formed. The use of the cover plate on the steel pipe of the lifting point is that when it is used as a barge, the cover plate is used to cover the structure of the lifting point, which does not affect the loading of the deck and ensures that the structure of the lifting point is intact and dry. The steel pipe of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com