Dust removing device for glass production line

A technology of dust removal device and processing line, which is applied in the direction of glass cutting device, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of a lot of hair, dust, dust, uneven glass section, discontinuous cutting line, etc., and achieve reduction The glass breakage rate, the effect of improving cutting quality and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the substantial features and advantages of the present invention will be further described with reference to examples, but the present invention is not limited to the listed embodiments.

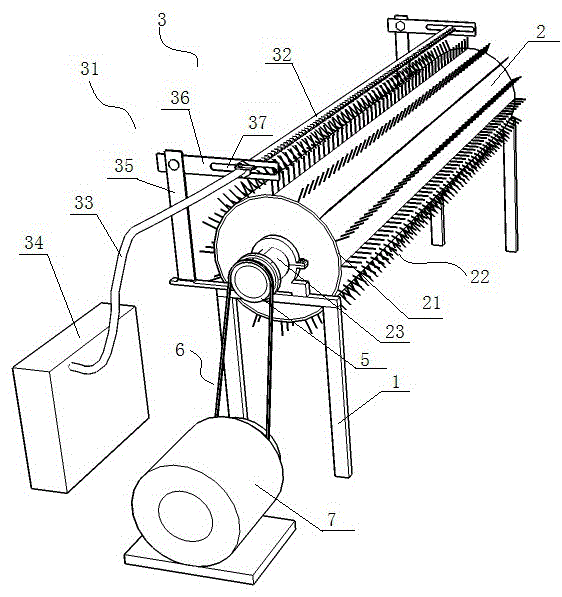

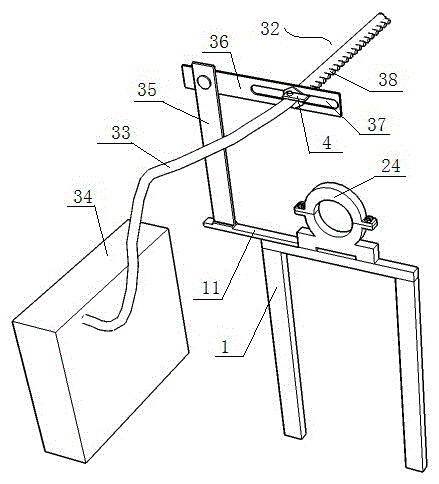

[0015] see figure 1 As shown in the figure, the figure shows the structure of a dust removal device for a glass processing line according to the embodiment of the present invention, and for the convenience of description, only the relevant part of the embodiment of the present invention is shown.

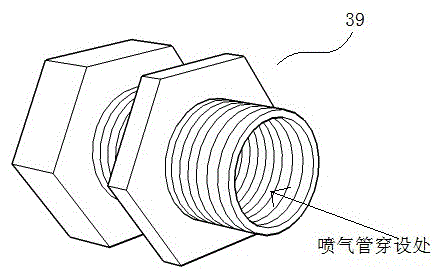

[0016] A dust removal device for a glass processing line is arranged between a film loading machine and a cutting table of the glass processing line, and its width is generally equal to the width of the cutting table according to the actual application, including a roller 2 arranged on a pair of support frames 1, The height of the roller 2 is set slightly lower than the conveying plane height of the film loading machine and the cutting table, so that the glass can be conveyed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com