A kind of table tennis racket positive glue rubber composite material

A technology of positive rubber and composite materials, applied in rackets, sports accessories, etc., can solve the problems of rubber hardness, shortened service life, difficulty in meeting high elasticity, high hardness, etc., and achieve fast return speed and stable hitting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of table tennis racket positive glue rubber composite material, and it comprises the raw material component of following parts by weight:

[0027] Natural rubber 50g;

[0028] Trans-1,4-polyisoprene rubber 30g;

[0029] 40g of butadiene rubber; (natural rubber, trans-1,4-polyisoprene rubber, and butadiene rubber are available conventionally);

[0030] Polyvinylimidazole (number average molecular weight 10000) 30g;

[0031] Hydroxy acrylic resin (number average molecular weight 10000) 20g;

[0033] 2,2'-dithiodibenzothiazole 2g;

[0034] Sulfur 1g;

[0035] 2,6-di-tert-butyl-p-cresol 2g;

[0036] Nanoscale titanium dioxide 10g.

[0037] The preparation method of above-mentioned table tennis racket positive glue rubber composite material comprises the following steps:

[0038] (1) The natural rubber, trans-1,4-polyisoprene rubber, butadiene rubber, polyvinylimidazole, and hydroxy acrylic resin ble...

Embodiment 2

[0041] This embodiment provides a kind of table tennis racket positive glue rubber composite material, and its preparation method is consistent with the embodiment 1, and the difference is that it includes the following raw material components in parts by weight:

[0042] Natural rubber 80g;

[0043] Trans-1,4-polyisoprene rubber 10g;

[0044] Butadiene rubber 10g;

[0045] Polyvinylimidazole (number average molecular weight 100000) 10g;

[0046] Hydroxy acrylic resin (number average molecular weight 100000) 10g;

[0048] 2-mercaptobenzothiazole 0.1g;

[0049] Sulfur 0.1g;

[0050] 2,2,4-trimethyl-1,2-dihydroquinoline polymer 0.1g;

Embodiment 3

[0053] This embodiment provides a kind of table tennis racket positive glue rubber composite material, and its preparation method is consistent with the embodiment 1, and the difference is that it includes the following raw material components in parts by weight:

[0054] Natural rubber 60g;

[0055] Trans-1,4-polyisoprene rubber 20g;

[0056] Butadiene rubber 20g;

[0057] Polyvinylimidazole (number average molecular weight 75000) 20g;

[0058] Hydroxy acrylic resin (number average molecular weight 75000) 15g;

[0059] Stearic acid 8g;

[0060] Diphenylguanidine 1g;

[0061] Sulfur 0.5g;

[0062] 0.5 g of 2,6-di-tert-butyl-p-cresol.

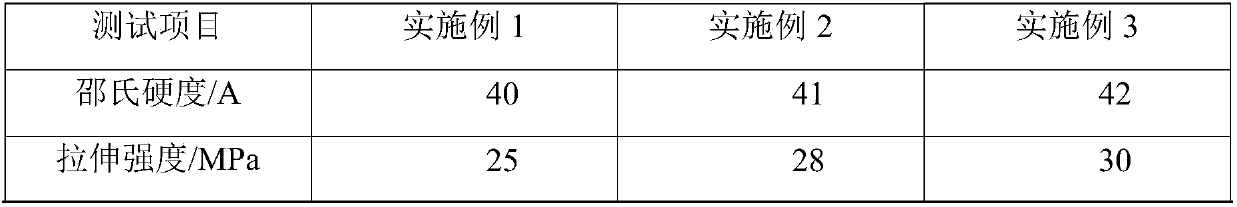

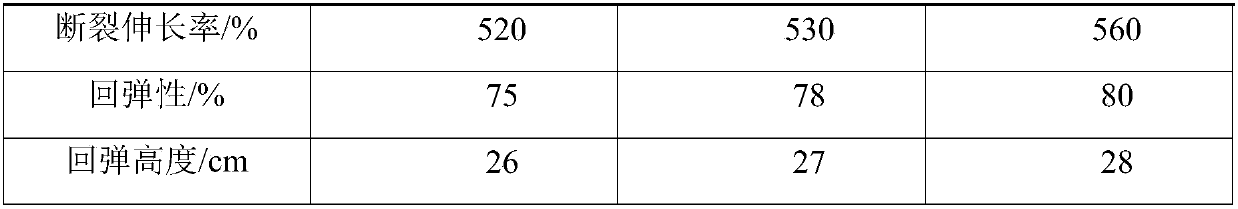

[0063] The table tennis racket positive rubber rubber composite material prepared in the above examples is subjected to a performance test, and the specific data are listed in Table 1.

[0064] Table 1 Table tennis racket positive rubber rubber composite performance test data table

[0065]

[0066]

[0067] Note: The rebound heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com