Highly weather-resistant aesthetic resin and preparation method thereof

A technology of aesthetic resin and high weather resistance, which is applied in the field of high weather resistance aesthetic resin and its preparation, can solve the problems of restricting the application of aesthetic resin, achieve excellent weather resistance, promote dispersion, and improve the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

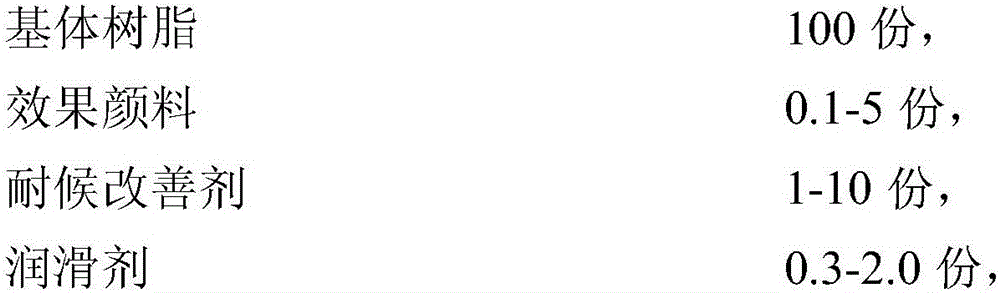

[0028] The high weather-resistant aesthetic resin described in this embodiment includes the following components in parts by weight:

[0029]

[0030] Among them, the matrix resin is one of high-gloss ABS, transparent ABS, ABS / PMMA alloy, PMMA, transparent HIPS, GPPS, high-gloss PP, PC / ABS alloy, PC, PET, PBT or ASA; effect pigment 1 is glass flake , the particle size is 50-200 μm; the weather resistance improving agent 1 is nano zinc oxide, the particle size is 1-100 nm; the lubricant is barium stearate; the antioxidant is Irganox B900.

[0031] Preparation:

[0032] (1) prepare materials according to the above-mentioned components and parts by weight;

[0033] (2) fully mix the materials prepared in the step (1) in a high-speed mixer;

[0034] (3) Send the premixed material obtained in step (2) into the twin-screw extruder through the metering device, and control the temperature of the twin-screw extruder to be 170-240° C. and 200-500 rpm under the screw speed condition...

Embodiment 2

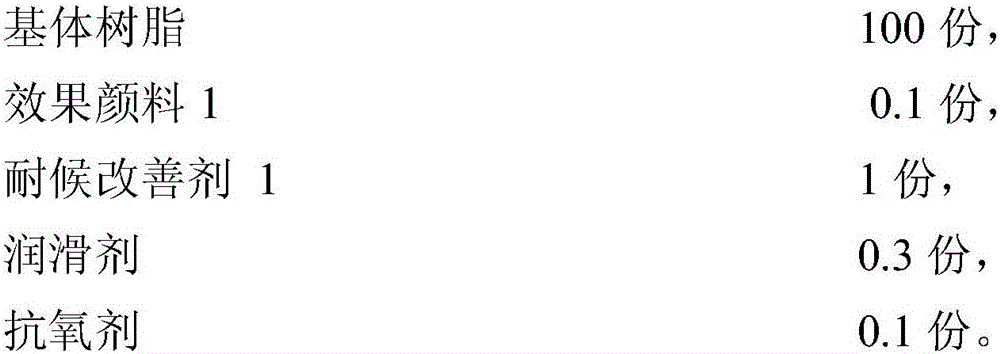

[0036] The high weather-resistant aesthetic resin described in this embodiment includes the following components in parts by weight:

[0037]

[0038] Among them, the matrix resin is one of high-gloss ABS, transparent ABS, ABS / PMMA alloy, PMMA, transparent HIPS, GPPS, high-gloss PP, PC / ABS alloy, PC, PET, PBT or ASA; effect pigment 1 is glass flake , the particle size is 50-200 μm; the weather resistance improving agent 2 is nano silicon dioxide, the particle size is 5-100 nm; the lubricant is barium stearate; the antioxidant is Irganox B900.

[0039] Preparation:

[0040] (1) prepare materials according to the above-mentioned components and parts by weight;

[0041] (2) fully mix the materials prepared in the step (1) in a high-speed mixer;

[0042] (3) Send the premixed material obtained in step (2) into the twin-screw extruder through the metering device, and control the temperature of the twin-screw extruder to be 170-240° C. and 200-500 rpm under the screw speed cond...

Embodiment 3

[0044] The high weather-resistant aesthetic resin described in this embodiment includes the following components in parts by weight:

[0045]

[0046] Among them, the matrix resin is one of high-gloss ABS, transparent ABS, ABS / PMMA alloy, PMMA, transparent HIPS, GPPS, high-gloss PP, PC / ABS alloy, PC, PET, PBT or ASA; the effect pigment 2 is metal aluminum The pigment has a particle size of 20-100 μm; the weather resistance improving agent 1 is nano zinc oxide, and the particle size is 1-100 nm; the lubricant is magnesium stearate; and the antioxidant is Irganox 168.

[0047] Preparation:

[0048] (1) prepare materials according to the above-mentioned components and parts by weight;

[0049] (2) fully mix the materials prepared in the step (1) in a high-speed mixer;

[0050] (3) Send the premixed material obtained in step (2) into the twin-screw extruder through the metering device, and control the temperature of the twin-screw extruder to be 170-240° C. and 200-500 rpm un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com