Aluminum alloy billet for magnetic disk and aluminum alloy substrate for magnetic disk

A technology of aluminum alloy and billet, applied in the base layer of the recording layer, magnetic recording, magnetic recording layer, etc., can solve the problems of performance degradation, micro ripples cannot be removed, etc., and achieve excellent impact strength, surface smoothness, and excellent yield The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] First, an embodiment of a blank will be described.

[0040] The raw material in this embodiment includes Mg: 4.5 mass % or more and 6.0 mass % or less, Mn: 0.10 mass % or more and 0.55 mass % or less, Si: 0.025 mass % or less and Fe: 0.025 mass % or less, and the balance is Al and unavoidable impurities.

[0041] The blank in the present invention has the following characteristics: the average grain size on the surface is 27 μm or less, the aspect ratio of the average grain size on the surface is 1.2 or less, and the yield strength is 140 MPa or more.

[0042] The ingredient composition of the blank in this embodiment is described below, and then, the state of the recrystallized structure and the mechanical properties are described.

[0043]

[0044] (Mg)

[0045] Mg is an element effective for improving the yield strength of a billet. When the amount of Mg is less than 4.5% by mass, sufficient yield strength may not be obtained and the impact strength of the bille...

Embodiment

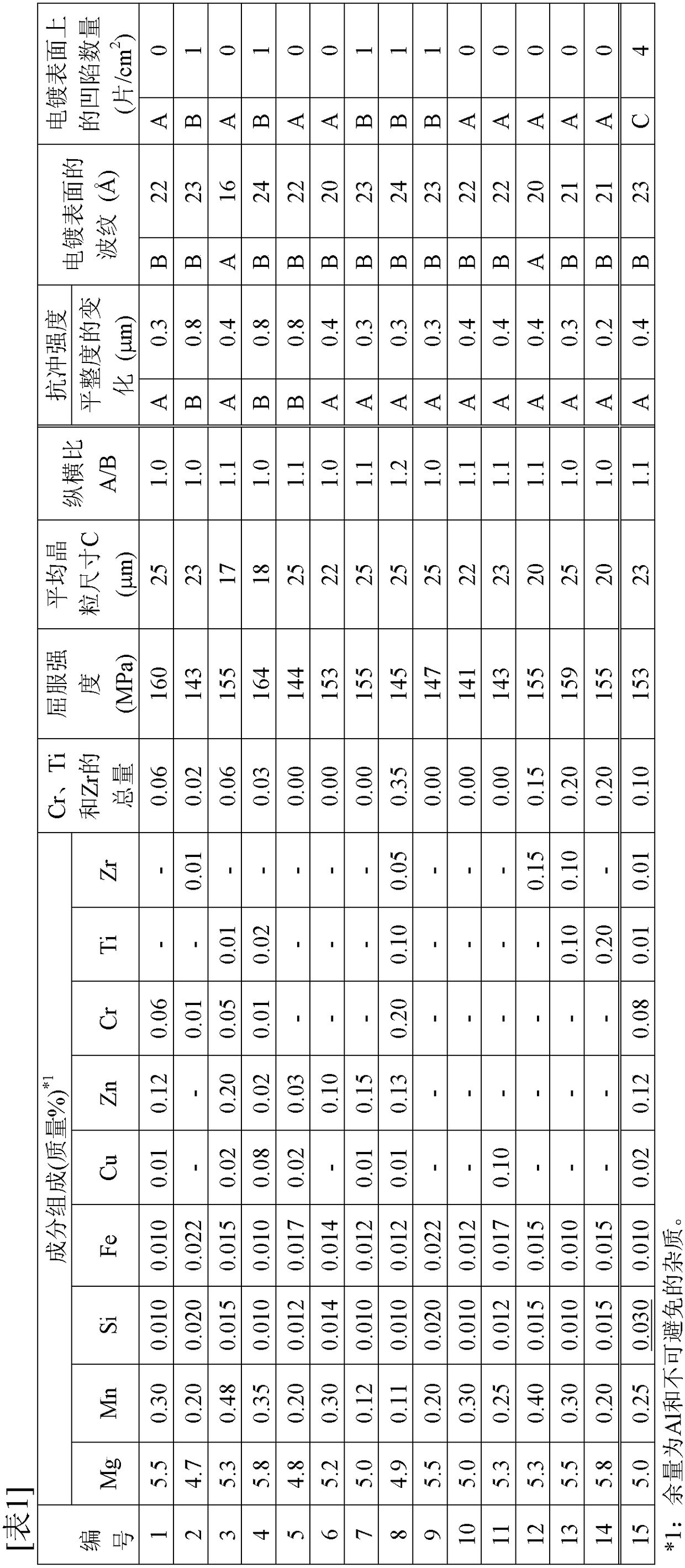

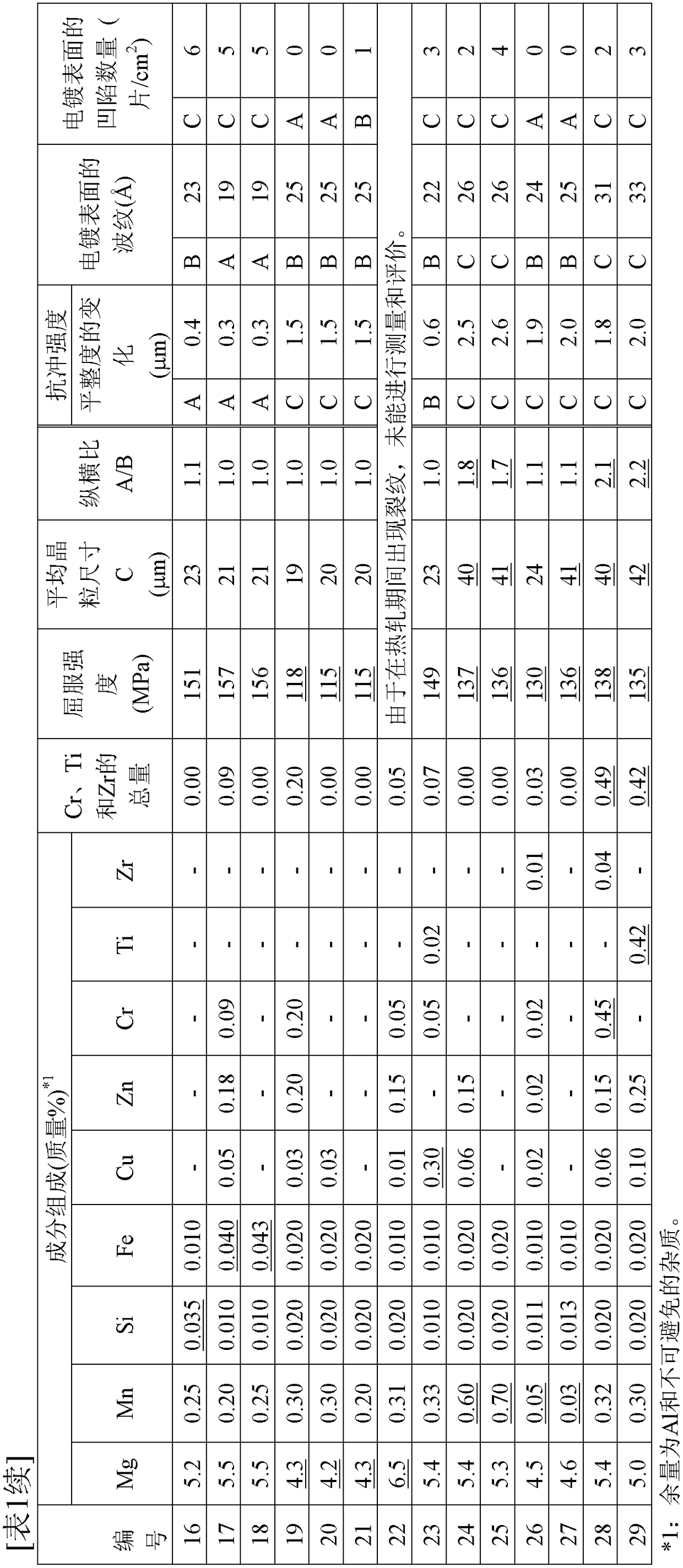

[0136] The contents of the present invention will be specifically described below with reference to Examples exhibiting the advantageous effects of the present invention and Comparative Examples not exhibiting the advantageous effects of the present invention.

[0137] First, the material was melted at 700° C., the composition was adjusted to have the component compositions shown in Nos. 1 to 43 of Table 1, and an ingot was cast.

[0138] Next, peeling for removing the segregation layer on the surface of each ingot was performed, and the ingot was kept at 530 to 560° C. for 4 hours. After that, heat treatment for homogenization is performed by maintaining it at 510 to 530° C. for 0.5 to 12 hours.

[0139] Immediately after the heat treatment for homogenization, hot rolling was started to prepare a hot-rolled sheet having a thickness calculated from a predetermined cold-rolling reduction ratio and a processed sheet thickness. Hot rolling was performed to complete within 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com