A super-high water head planar sliding accident gate groove structure

An emergency gate and high water head technology, which is applied in water conservancy projects, marine engineering, construction, etc., can solve problems such as cavitation, cavitation, water column cannot be closed, concrete damage, etc., so as to improve hydraulic conditions and reduce cavitation Effects of cavitation and wind speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

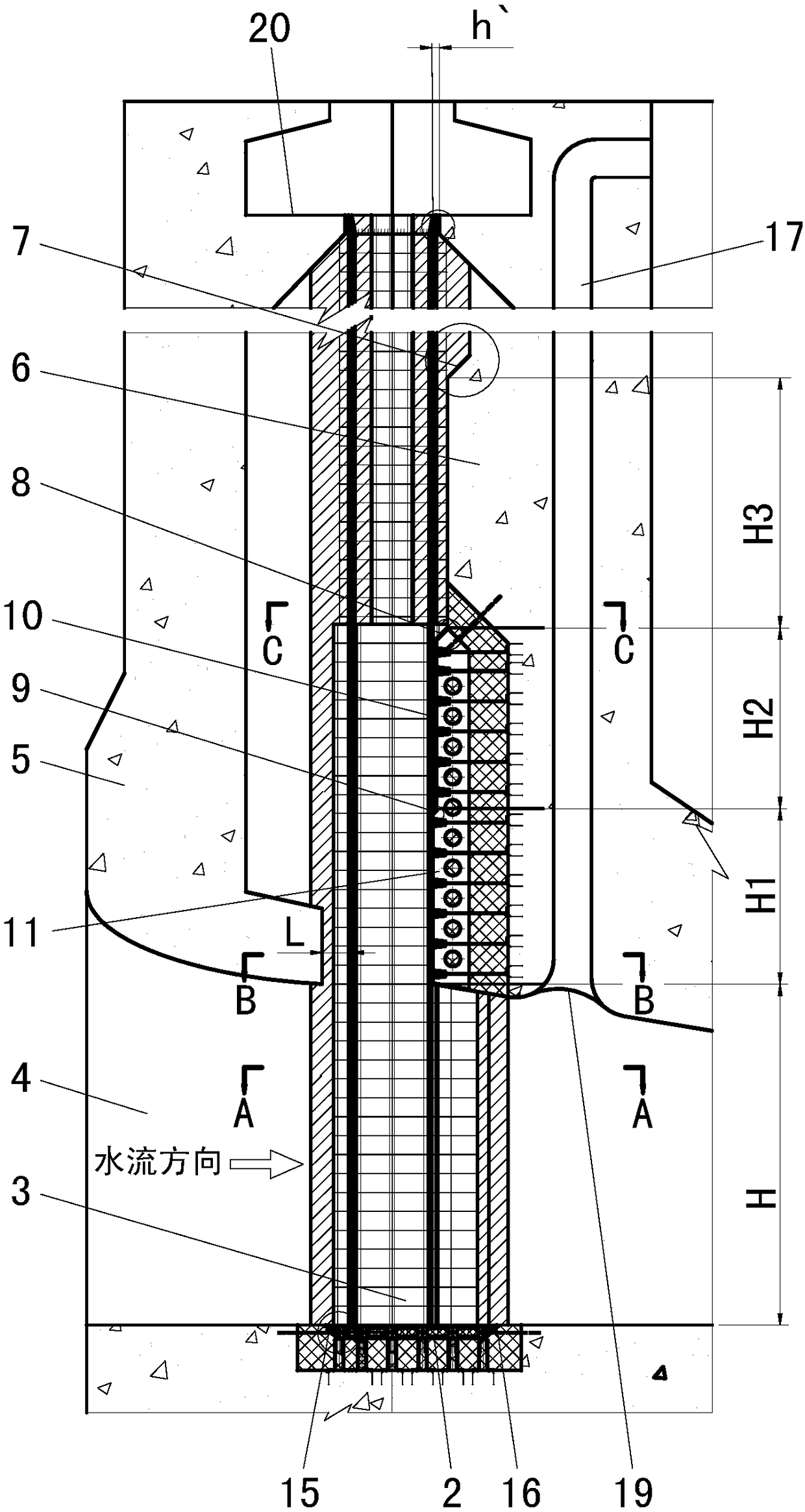

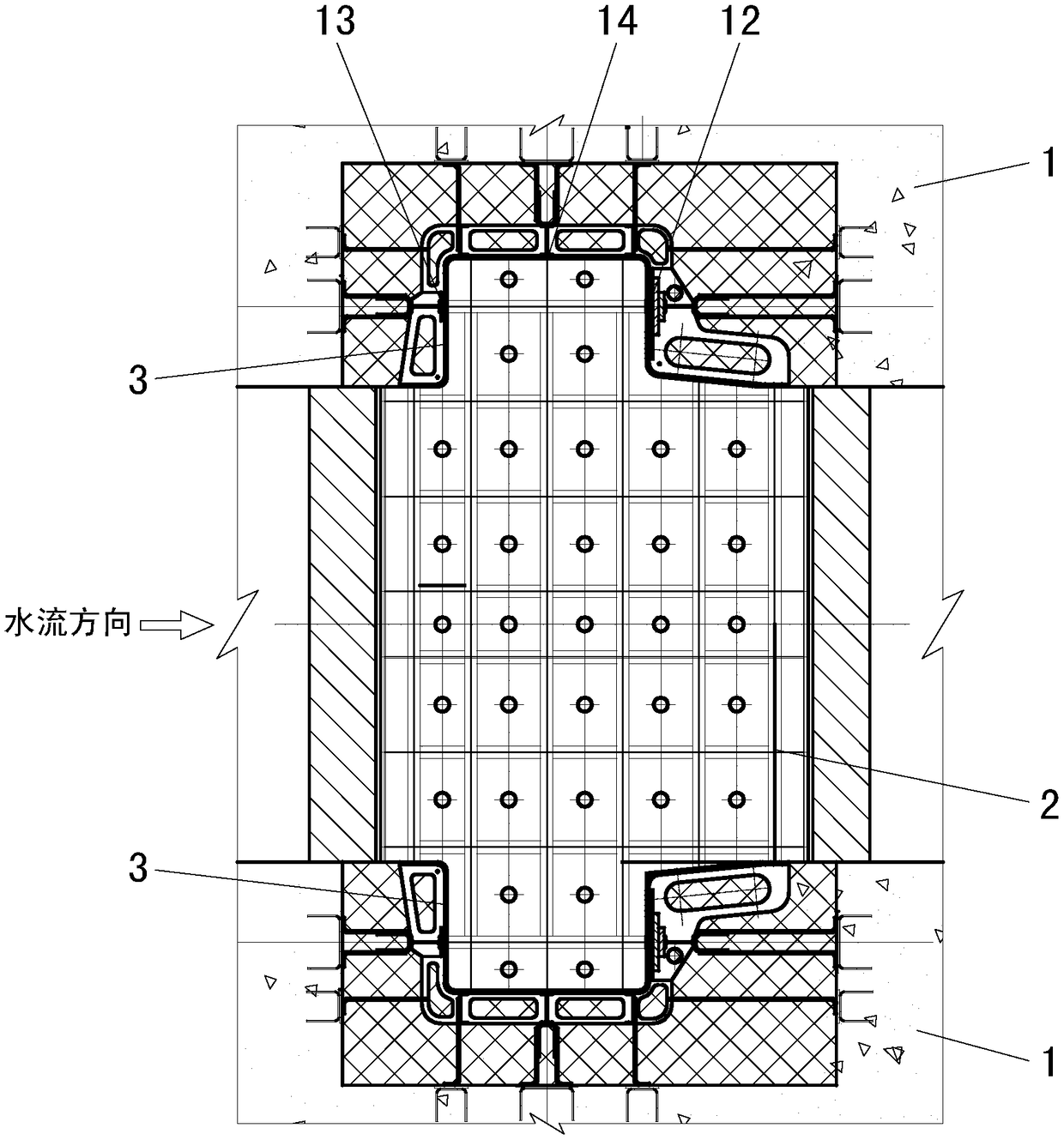

[0051] The extra-high water head planar sliding emergency gate groove in this example includes an upstream parapet 5 , a gate slot 3 and a downstream parapet 6 .

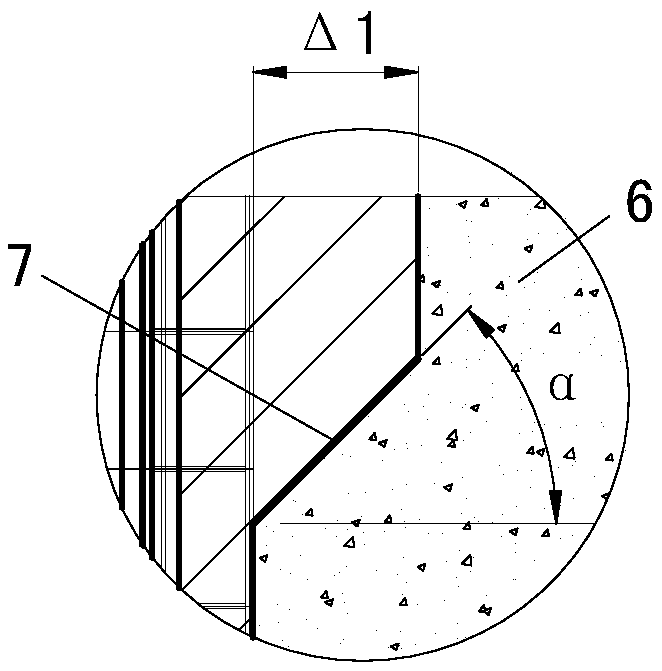

[0052] The relationship between the width W of the door slot and the depth D of the door slot is: W / D=1.55~2.0; the heights on both sides of the door slot 3 are different, and the relationship between the height difference △ and the width W of the door slot is: △ / W=0.05~0.08; The relationship between the height difference △ and the slope length X is △ / X=0.05~0.1; the outer corner of the upstream facing water surface of the door slot 3 is rounded, and the fillet radius R1=50~200mm, preferably 80mm or 100mm; the inner corner of the door slot 3 is rounded , the fillet radius R2=50~200mm, 80mm or 100mm is preferred; the external fillet of the downstream surface of the door slot 3, the relationship between the fillet R3 and the depth D of the door slot is: R3=0.1D, 50mm or 100mm is preferred; the upstream The relationshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com