Treatment method of kitchen waste

A treatment method and a technology of kitchen waste, which are applied in the direction of the device whose axial direction of the swirl can be reversed, the waste fuel, the swirl device, etc., can solve the problems of low quality, poor pretreatment working environment, etc., and achieve the oil extraction rate High efficiency, improved work efficiency and quality, less waste of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

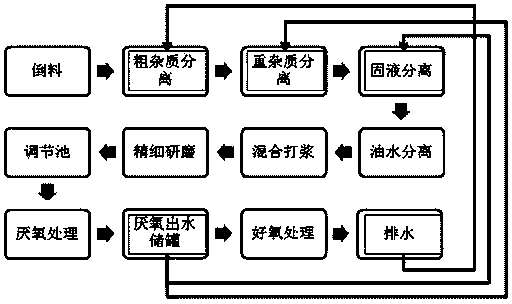

[0078] Such as figure 1 As shown, the collected food waste is poured into a collecting hopper, the output of the collecting hopper is connected with the input of the equipment used in the next step of coarse impurities separation, and the food can be transported by conventional conveyor belts, conveyor chains, etc. Trash to the next processing step. Bag breaking device, magnetic sorting device and other devices conventionally used for preliminary sorting of kitchen waste can be additionally set up during the dumping and transportation process to deal with the bag breaking and magnetic sorting of kitchen waste to remove the metal in the kitchen waste. The ingredients and no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com