Mine grouting anchor cable supporting method

A technology of grouting anchor cables and grouting, which is applied in mining equipment, earthwork drilling, bolt installation, etc., can solve the problems of difficult construction, small support range, and low support strength, and achieve simplified construction procedures, The effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] A support method for grouting anchor cable bundles used in mines, comprising processing and manufacturing the grouting anchor cable bundles and installing and supporting the grouting anchor cable bundles.

[0044] 1) Processing and production of grouting anchor bundles:

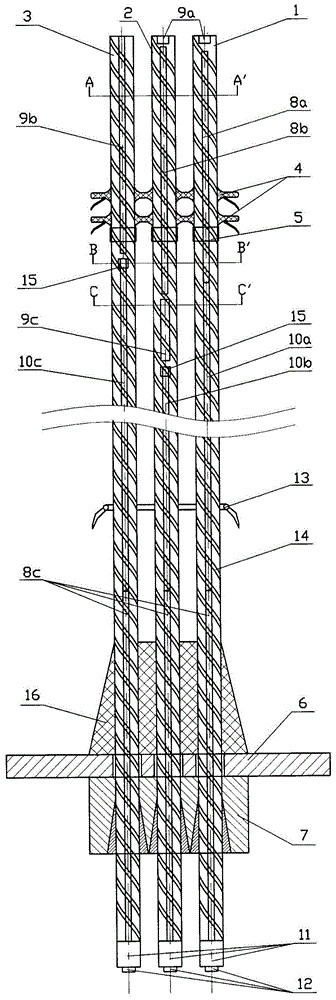

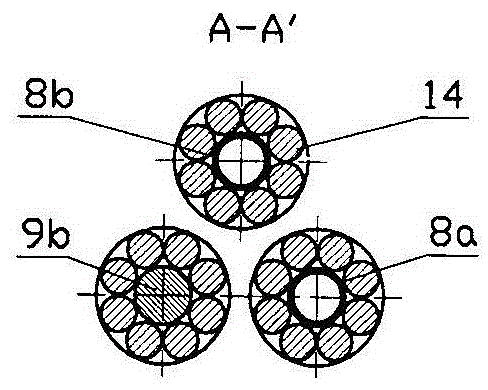

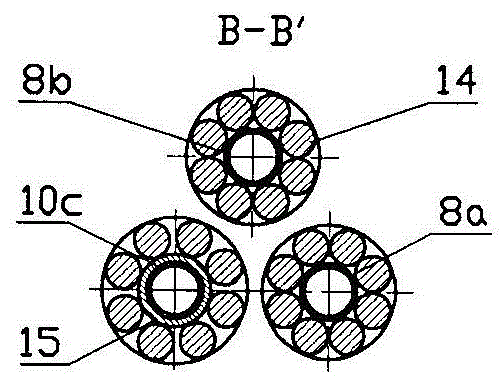

[0045] exist figure 1 A structure of the mine grouting anchor bundle used in the present invention is shown in . The "multiple anchor cable bodies" of the illustrated grouting anchor cable bundle are three anchor cable bodies, and are three grouting anchor cable bodies with different purposes. These three kinds of grouting anchor cable bodies are: end anchor grouting anchor cable body 1 , full anchor grouting anchor cable body 2 , exhaust grouting anchor cable body 3 . In this example, one each of the end anchor grouting anchor cable body 1, the full anchor grouting anchor cable body 2, and the exhaust grouting anchor cable body 3 is used, and the components that are sleeved on the three grouting anc...

Embodiment approach

[0079] 1. In the embodiment, the grouting anchor cable bundle is composed of three kinds of grouting anchor cable bodies, the end anchor grouting anchor cable body, the full anchor grouting anchor cable body and the exhaust grouting anchor cable body. It can increase the number of each type of grouting anchor cable body according to needs, and can also increase one or more cable bodies of ordinary anchor cables, that is, non-grouting anchor cables.

[0080] 2. After the installation and support of the grouting anchor cable bundle is completed, according to the deformation of the roadway, secondary grouting can also be performed on the core pipe of the unblocked exhaust grouting anchor cable body used as the exhaust pipe, Strengthen the newly developed surrounding rock fissures. At this time, the exhaust port at the upper end of the flexible circular pipe III (10c) of the exhaust grouting anchor cable body 3 is used as a grout outlet for secondary grouting.

[0081] 3. A spare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com