Two-stage internal gear pump

A technology of internal gear pump and pump casing, applied in the direction of pump, pump components, pump control, etc., can solve the problem that the gear pump cannot meet the working requirements of the high-pressure hydraulic system, and achieves the improvement of gap leakage, high pump hydraulic pressure and working conditions. Efficiency and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

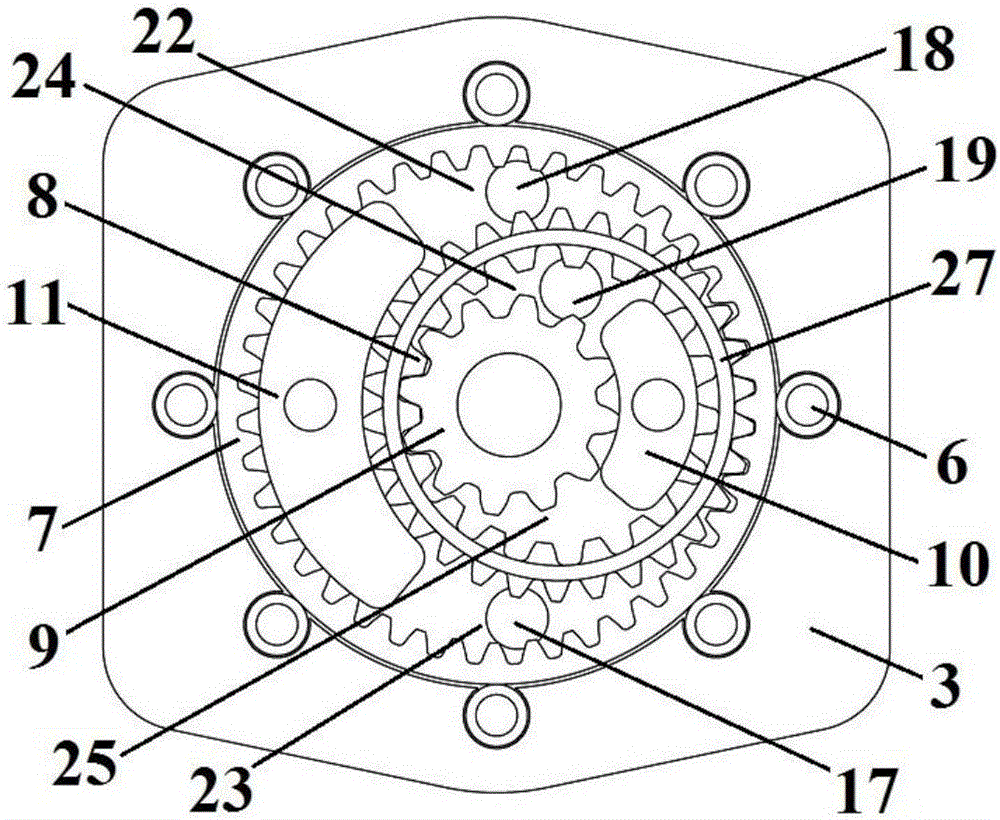

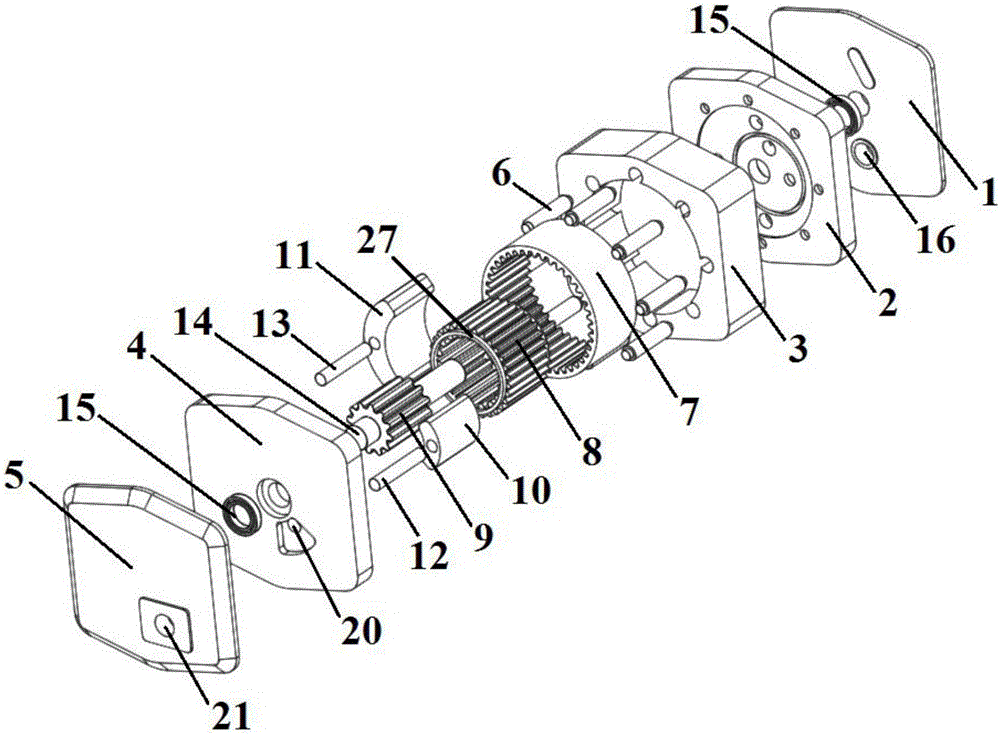

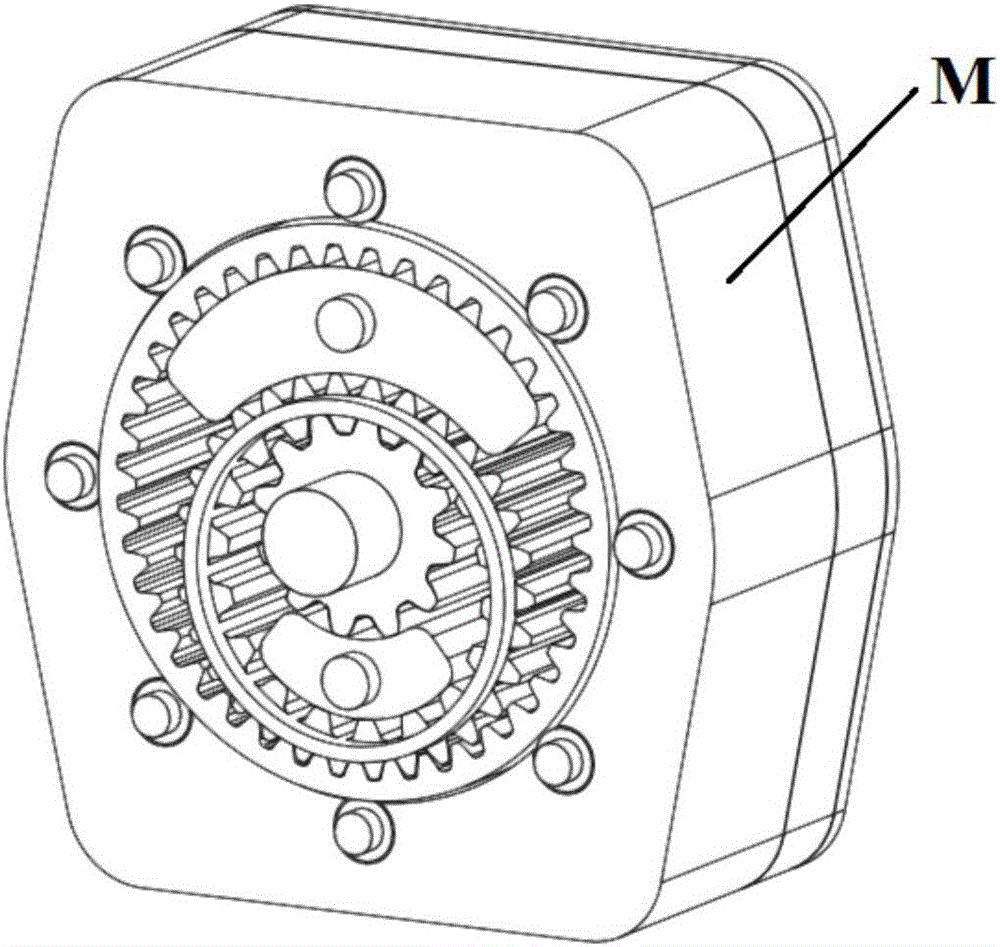

[0026] The two-stage internal gear pump shown in the figure includes an outer rotor 7, an intermediate rotor 8 and an inner rotor 9 closed by a sealing member M, and also includes a high-pressure sealing block 10 and a low-pressure sealing block 11, an outer rotor 7, an intermediate rotor 8 and the inner rotor 9 are sequentially meshed from outside to inside, the inner rotor 9 is connected to the power input device, and the high-pressure sealing block 10 and the sealing member M separate the inner rotor 9 and the intermediate rotor 8 into a closed secondary low-pressure area 24 and Secondary high-pressure zone 25, the low-pressure sealing block 11 and sealing member M separate the intermediate rotor 8 and the outer rotor 7 into a closed primary low-pressure zone 23 and a primary high-pressure zone 22, wherein the primary low-pressure zone 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com