System and method for reducing power consumption of dry pump

A dry pump and power consumption technology, which is applied to pumps, pump combinations for elastic fluid rotary piston type/oscillating piston type, machines/engines, etc., can solve the problems of dry pump consumption, large power consumption, etc., and reduce load power , The effect of reducing loss and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

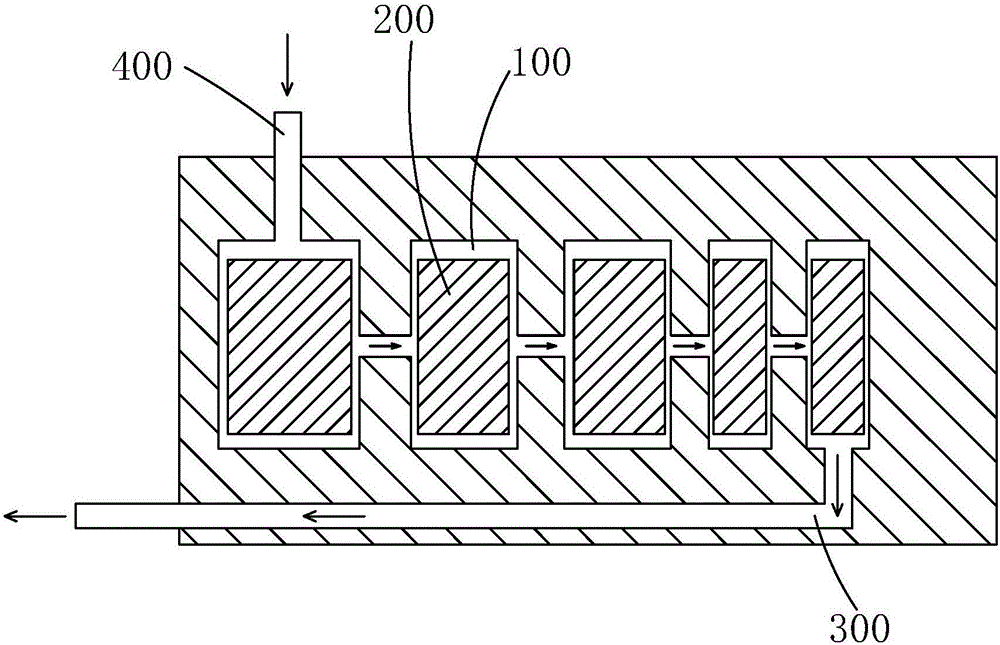

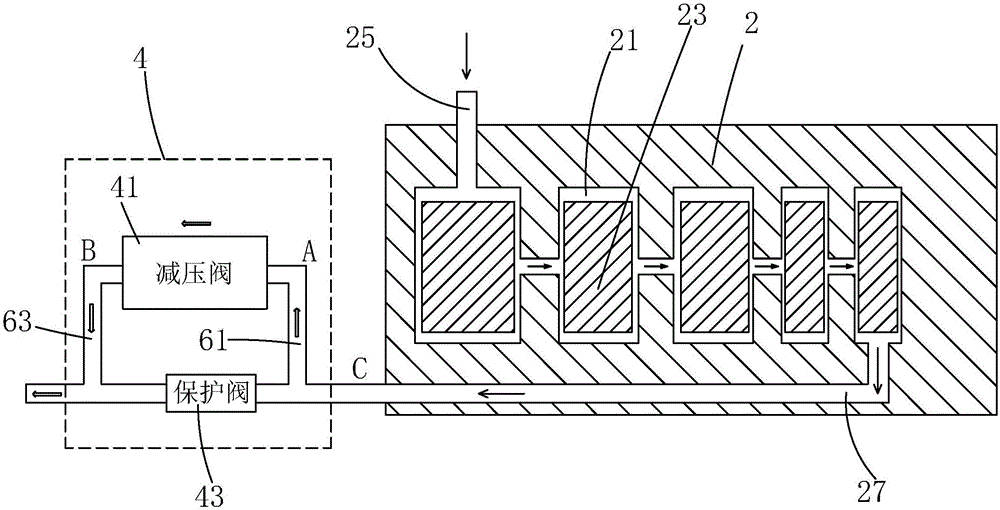

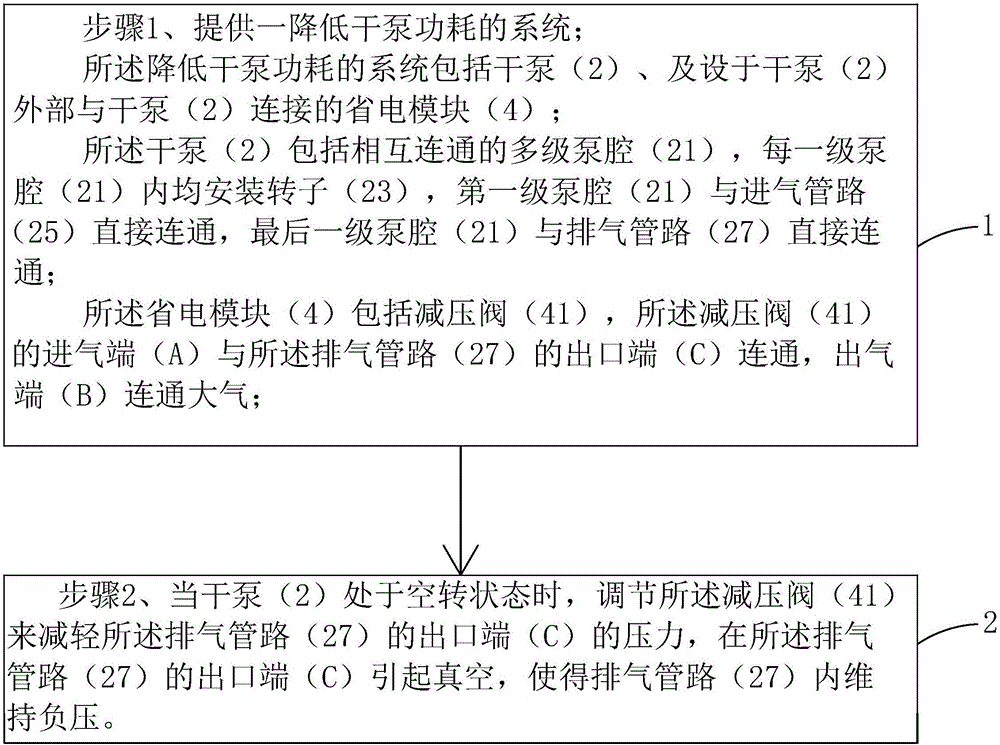

[0029] see figure 2 Firstly, the present invention provides a system for reducing power consumption of a dry pump, including a dry pump 2 and a power saving module 4 arranged outside the dry pump 2 and connected to the dry pump 2 .

[0030] The dry pump 2 includes multi-stage pump chambers 21 that communicate with each other. A rotor 23 is installed in each pump chamber 21. The first-stage pump chamber 21 is directly connected to the intake pipeline 25, and the last-stage pump chamber 21 is connected to the exhaust pipe. Pipeline 27 communicates directly. When the dry pump 2 is working, each rotor 23 rotates, so that the volume of the corresponding pump chamber 21 changes periodically, and the air pumping is realized by using the opening and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com