Perforated drum of an axial turbine-engine compressor

A technology for turbine engines, compressors, applied in the direction of engine functions, engine components, components of pumping devices for elastic fluids, etc., can solve problems such as unsatisfactory solutions, achieve small damage, and reduce the risk of clogging , the effect of simple geometric structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the following description, the terms inner or inner and outer or outer relate to a position relative to the axis of rotation of the axial turbine engine. The axial direction corresponds to a direction along the axis of rotation of the turbine engine. Upstream and downstream are referred to with reference to the main flow direction of the flow in the turbine engine.

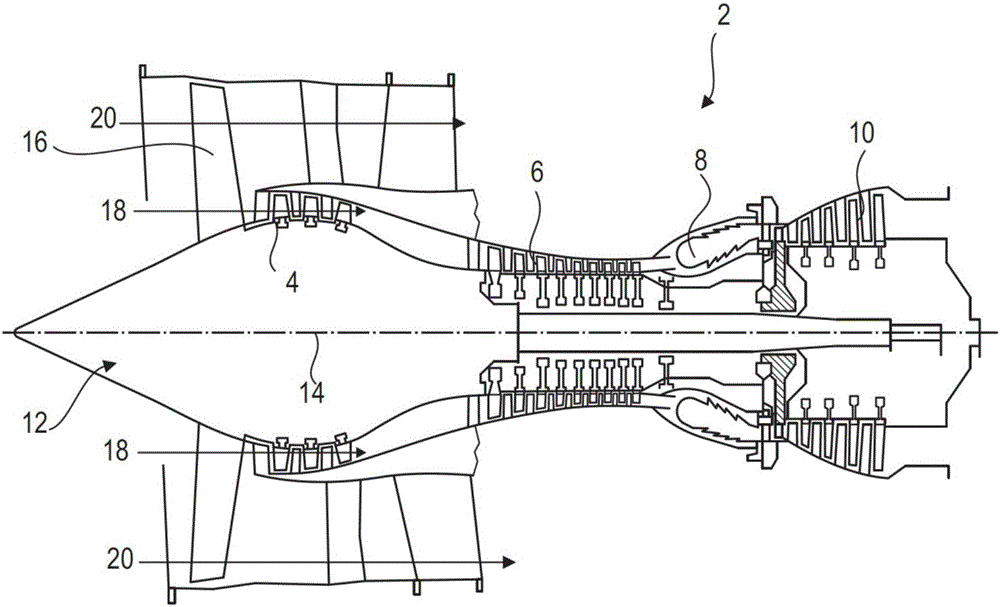

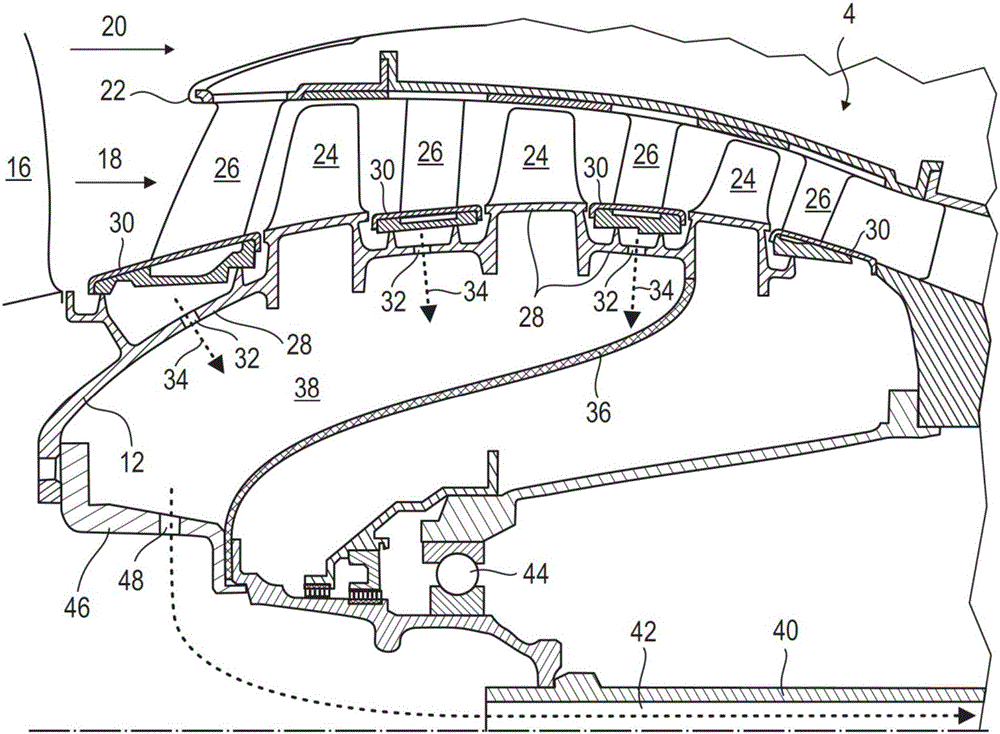

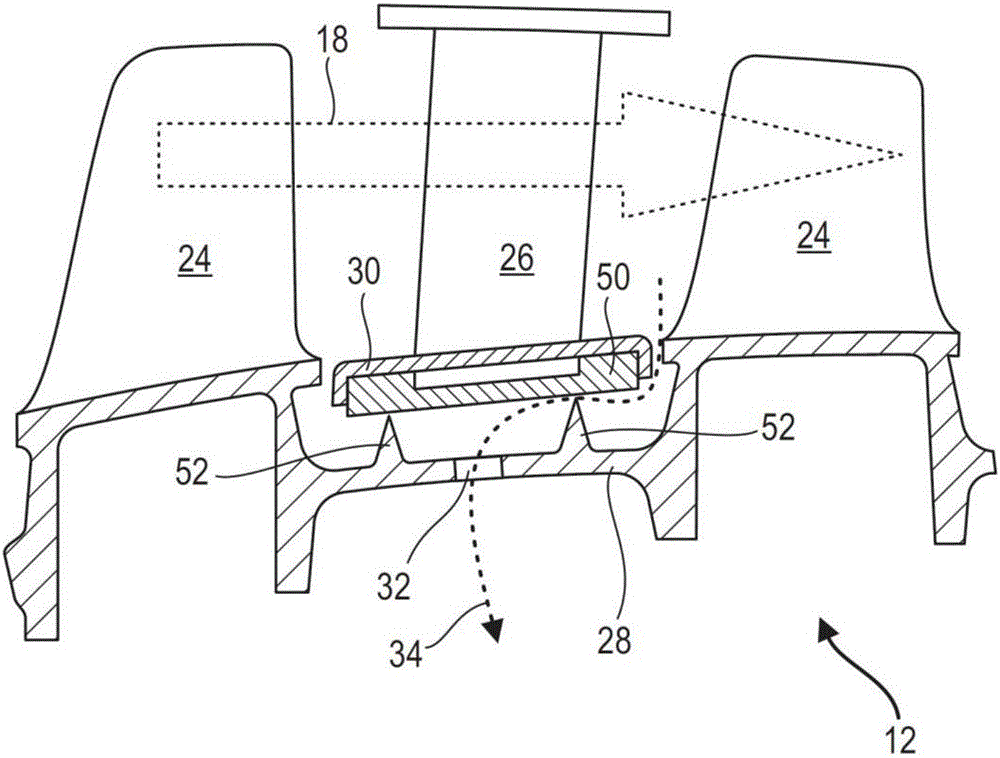

[0054] figure 1 An axial turbine engine is shown in a simplified manner. In this precise case, it's the ducted fan turbine engine used to power the aircraft. The turbojet engine 2 comprises a first compression stage called a low-pressure compressor 4 , a second compression stage called a high-pressure compressor 6 , a combustion chamber 8 and a one- or multi-stage turbine 10 . In operation, the mechanical power of the turbine 10 , transmitted via the central shaft to the rotor 12 , moves the two compressors 4 and 6 . The latter includes rows of rotor blades associated with rows of stator blades. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com