3D glass candle lamp and manufacturing method thereof

A production method and technology of candle lamps, applied in lampshades, special patterns, decorative arts, etc., can solve the problems that three-dimensional graphics and lights cannot achieve 3D three-dimensional reality, and achieve the effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

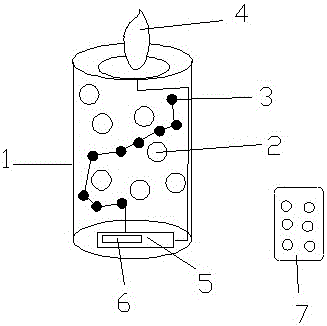

[0030] 1) Select transparent glass and clean it with detergent; 2) Use vacuum plating to uniformly plate chrome on the inside of the glass, the vacuum plating time is 8 minutes, and the oxygen flux is 320sccm; 3) According to the design requirements, laser circles on the glass 2; 4) Spray protective paint evenly on the electroplated chrome layer, and coat red colored sand on the protective paint; 5) Electroplate red film on the outside of the glass; 6) Spray electrostatic paint on the outside of the glass to obtain a 3D glass lampshade 1; 7) Install the LED light string 3 inside the lampshade 1, install the flame-shaped candle lamp bead 4 on the top of the lampshade 1, and connect the power supply device 5 fixedly to seal the lampshade 1.

Embodiment 2

[0032] 1) Select transparent glass and clean it with detergent; 2) Use vacuum plating to evenly plate a chrome layer on the inside of the glass, the vacuum plating time is 12 minutes, and the oxygen flux is 280sccm; 3) According to the design requirements, laser stars on the glass Pattern 2; 4) Evenly spray protective paint on the electroplated chrome layer, and coat yellow colored sand on the protective paint; 5) Electroplate yellow film on the outside of the glass; 6) Spray electrostatic paint on the outside of the glass to obtain a 3D glass lampshade 1; 7 ) Install the LED light string 3 inside the lampshade 1, install the diamond-shaped candle lamp bead 4 on the top of the lampshade 1, connect the power supply device 5 fixedly, and seal the lampshade 1.

Embodiment 3

[0034] 1) Select transparent glass and clean it with detergent; 2) Use vacuum plating to evenly plate a chrome layer on the inside of the glass, the vacuum plating time is 10 minutes, and the oxygen flux is 300 sccm; 3) According to the design requirements, laser flowers are placed on the glass Pattern 2; 4) Evenly spray protective paint on the electroplated chrome layer; 5) Electroplate silver film on the outside of the glass; 6) Spray electrostatic paint on the outside of the glass to obtain 3D glass lampshade 1; 7) Install LED light strings inside lampshade 1 3. A heart-shaped candle lamp bead 4 is installed on the top of the lampshade 1, and the power supply device 5 is fixedly connected to seal the lampshade 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com