Oil temperature test device

A technology for testing device and oil temperature, applied in the direction of measuring device, thermometer, measuring heat, etc., can solve the problem of constant oil capacity and cannot be guaranteed, and achieve the effect of constant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

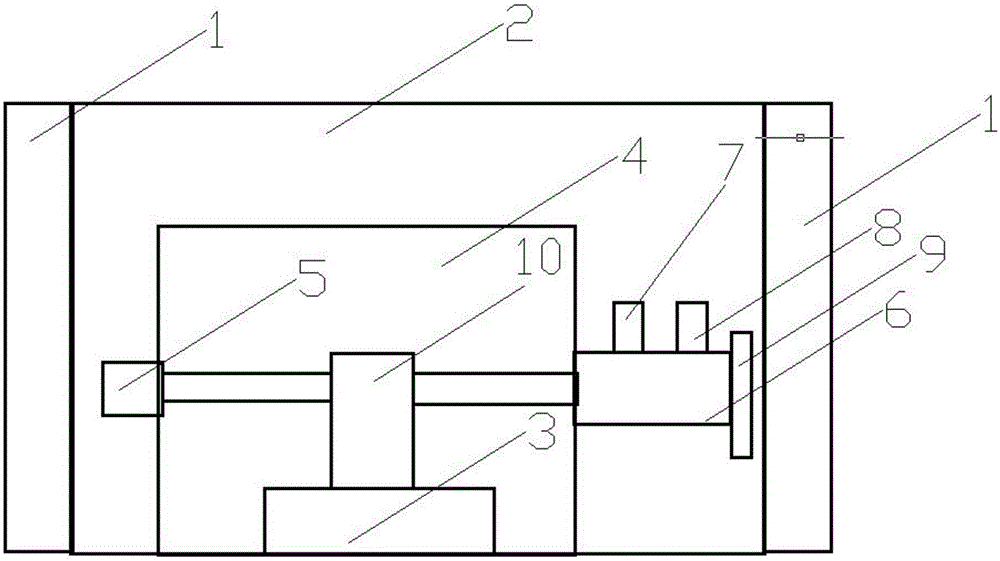

[0012] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0013] refer to figure 1 As shown, the oil temperature testing device includes a single hollow board box 2 with cooling fins 1, the material of the hollow board box 2 is a metal material, and a first temperature riser 3 is installed on the inner bottom surface of the hollow board box 2 , the casing 4 covers the first temperature riser 3, the casing 4 is connected with the inlet pipe 5, the casing 4 is also connected with the outlet pipe 6, the second temperature riser 7 and the valve 8 are arranged on the outlet pipe 6, and the outlet The pipe 6 is also connected with the oil bottle 9 containing oil. The inner surface of the oil bottle 9 is covered with a nitrile rubber layer, and a hollow metal box 10 is installed on the top of the first temperature riser 3. The hollow metal box 10 is connected with the introduction pipe 5 respectively. It is connected with outlet pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com