Dynamic performance test device for linear rotating motor and testing method

A rotary motor and dynamic performance technology, which is applied in the field of linear rotary motor dynamic performance test device, can solve the problems of low accuracy of test results, complicated operation, inability to realize multi-motion performance test, etc., to achieve convenient data sorting and analysis, and high measurement accuracy , The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

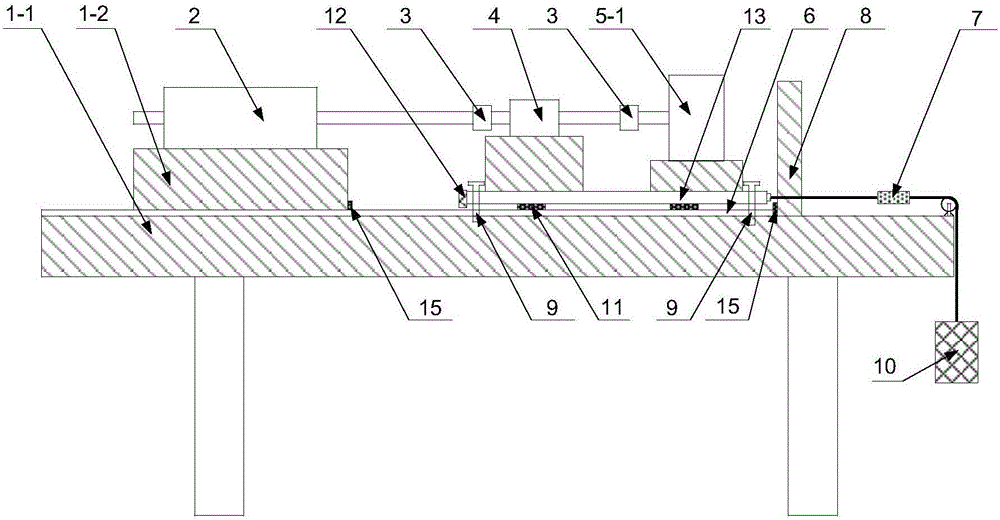

[0032] Embodiment 1, a kind of linear rotary motor dynamic performance testing device, such as figure 1 As shown; weight 10 is only used as a linear load, and the first rotating load 5-1 is a magnetic powder brake. The specific test method is as follows:

[0033] 1) When the device is performing a rotational motion test, insert the pin 9 into the position limiting hole to restrict the sliding of the second bottom plate 13, power the magnetic powder brake, start the linear rotary motor to perform rotational motion, and read it through the speed torque tester Speed and torque, record the data of each operating point, and then obtain the rotational motion load performance of the motor under test.

[0034] 2) When the device is performing a linear motion test, no pins are inserted in the position limiting hole, and a weight of 10 is hung on the wire rope to start the linear rotating motor to perform linear motion, and the thrust and displacement are read through the thrust senso...

Embodiment 2

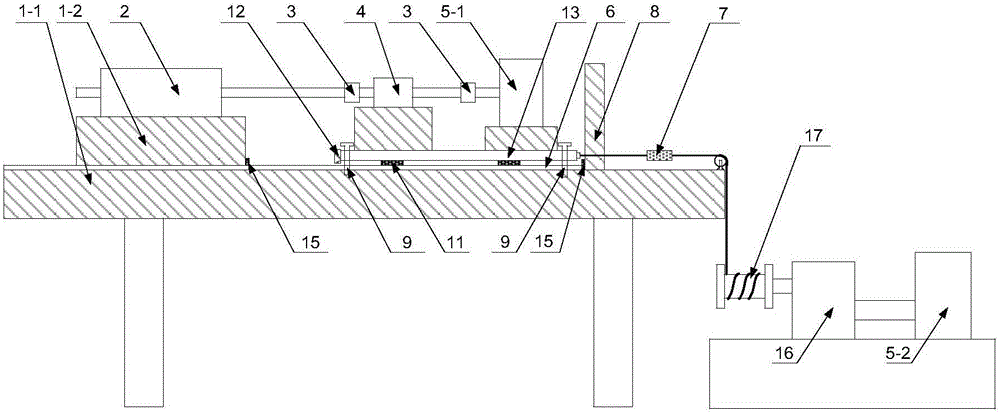

[0036] Embodiment 2, a kind of linear rotary motor dynamic performance testing device, such as figure 2 As shown; the line reel 17, the gearbox 16 and the rotating load 5-2 are combined to form a linear load, the gear ratio of the gearbox is 1:20, and the second rotating load 5-2 is a magnetic powder brake; the first rotating load 5-1 For magnetic powder brakes, the specific test methods are as follows:

[0037] 1) When the device is performing a rotational motion test, the pin 9 is inserted into the position limiting hole to restrict the sliding of the second bottom plate 13, the first rotational load 5-1 is energized, and the linear rotary motor under test is started to perform rotational motion, and through the speed rotation The torque tester reads the speed and torque, records the data of each operating point, and then obtains the rotational motion load performance of the motor under test.

[0038] 2) When the device is performing a linear motion test, the pin is not in...

Embodiment 3

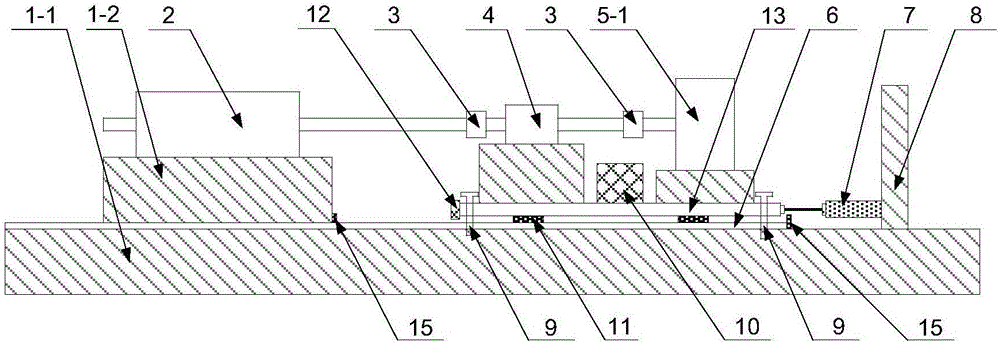

[0040] Embodiment 3, a kind of linear rotary motor dynamic performance testing device, such as image 3 As shown; the weight 10 is used as the linear load, and the first rotating load 5-1 is an eddy current dynamometer. The specific test method is as follows:

[0041] 1) When the device is performing a rotational motion test, insert the pin 9 into the position limiting hole to restrict the sliding of the second bottom plate 13, power on the eddy current dynamometer, start the linear rotary motor under test to perform rotational motion, and pass the speed and torque tester Read the rotational speed and torque, record the data of each operating point, and then obtain the rotational motion load performance of the motor under test.

[0042] 2) When the device is performing a linear motion test, no pins are inserted in the position limiting hole, and the weight 10 is placed on the second bottom plate, and the friction force of the slider that needs to be overcome by the linear moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com