An outer pin pressing area of a panel

A technology of press-fit area and outer pins, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problem of high cost, achieve the effects of improving yield, saving costs, and reducing the risk of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

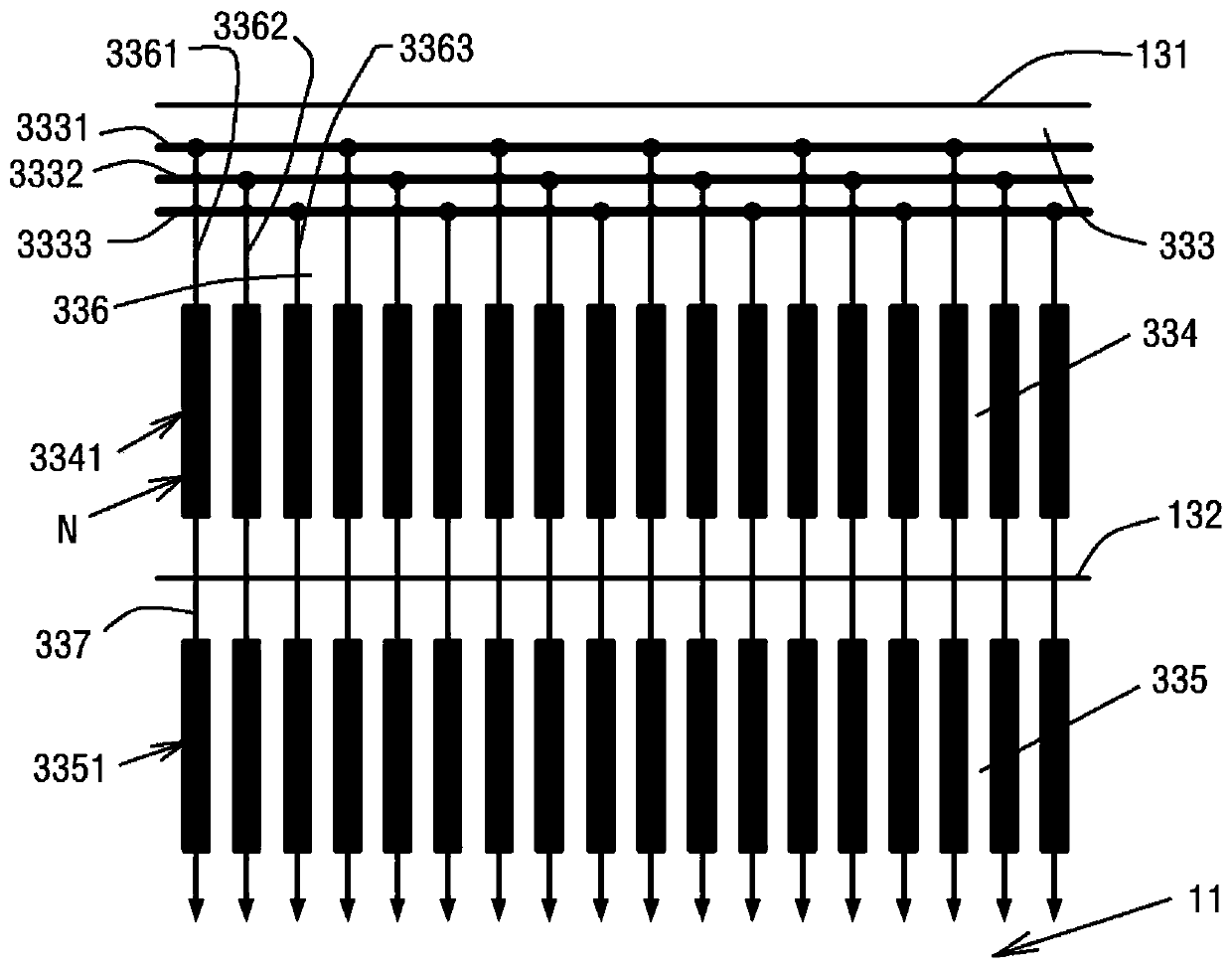

[0035] Such as image 3 It is a schematic diagram of the layout of the OLB area in the first embodiment of the present invention, including the first TFT cutting line 131, the first short wiring combination 333, the first group of bonding terminals 334, the second TFT cutting line 132, and the second group of bonding terminals 335. Display area 11.

[0036] combine image 3 To further illustrate, from the first TFT cutting line 131 to the display area 11, the first shorting wire combination 333, the first group of bonding terminals 334, the TFT second cutting line 132, the second Group bonding terminals 335 .

[0037] combine image 3 To further illustrate, the first short-circuit combination 333 and the first group of bonding terminals 334 are connected through a first metal wire 336, and the first group of bonding terminals 334 and the second group of bonding terminals 335 are connected through The second metal traces 337 are connected.

[0038] combine image 3 To fur...

Embodiment approach 2

[0045] Such as Figure 5 It is a schematic diagram of the layout of the OLB area in the second embodiment of the present invention, from Figure 5 It can be seen that in the second solution, a connecting unit 501 is added between the second TFT cutting line 132 and the second group of bonding terminals 335, and the connecting unit 501 is arranged on the second metal wiring 337 and disconnect the second metal trace 337 into two sub-segments 3371 and 3372 , and each of the second metal traces 337 is provided with one connection unit 501 .

[0046] combine Figure 5 To further illustrate, each of the connecting units 501 is staggered on the three adjacent second metal traces 337 and does not overlap each other. 6. 1+9... the connecting units are arranged on the same straight line, the 2nd, 2+3, 2+6, 2+9... the connecting units are arranged on the same straight line, the 3rd, 3+ 3, 3+6, 3+9... The connecting units are arranged on the same straight line.

[0047] combine Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com