A Radar/IR Compatible Stealth Metasurface

A metasurface, infrared technology, applied in antennas, electrical components, etc., can solve the problems of complex structure and poor performance of radar and infrared compatible stealth materials, achieve good radar and infrared compatible stealth performance, suppress grating lobe effect, and optimize bandwidth. The effect of thickness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

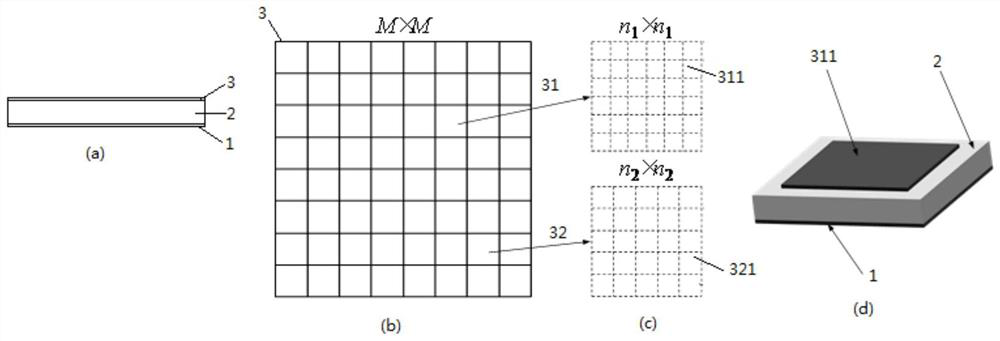

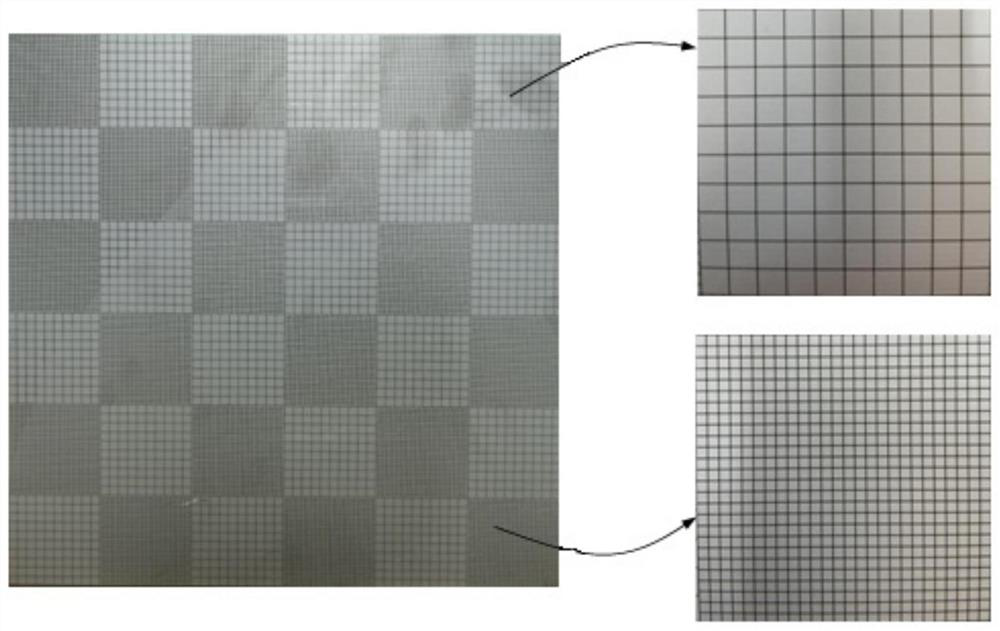

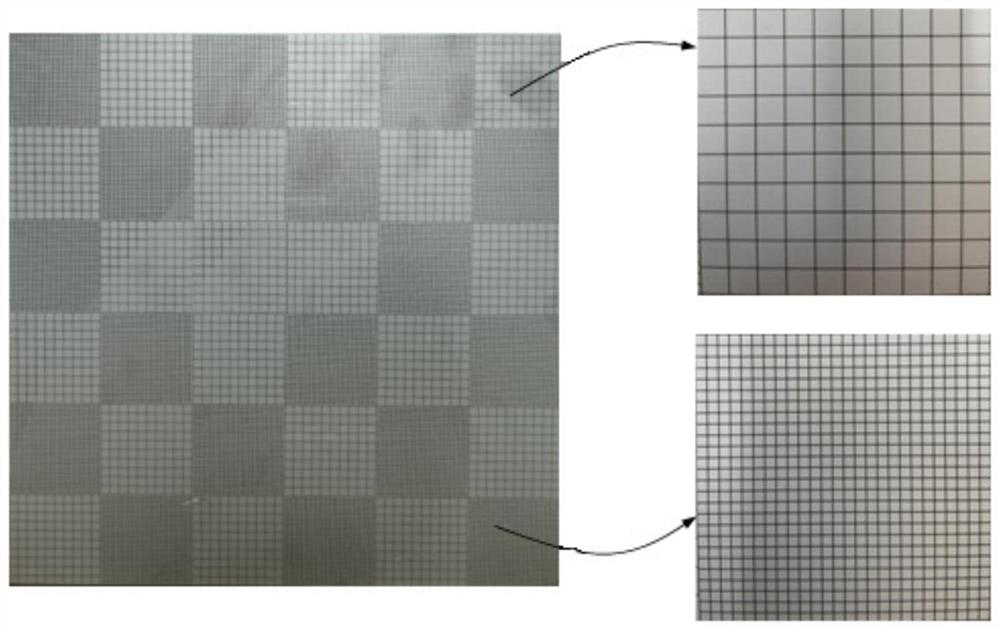

[0039] A radar / infrared compatible stealth metasurface, starting from the conductive metal copper reflective layer 1, from bottom to top, including FR4 dielectric layer 2 and conductive thin film functional layer 3, the thickness of the conductive metal copper reflective layer 1 is 0.02mm, and the FR4 dielectric layer The thickness is 1.5mm, the real part of the relative permittivity is 10, the loss tangent value is 0.2, and the functional layer of the conductor film is a metal copper film. The large unit II32 is arranged in a 6×6 array structure according to the checkerboard structure; the large patch unit I31 is arranged in a 26×26 structure by the small patch unit I311 with a size of 1.05mm, and the large patch unit II32 is composed of small patch units with a size of 2.97mm The small patch unit II321 is arranged in a 10×10 structure, the thickness of the patch small unit I311 and the patch small unit II321 are both 0.02mm, the gap between two adjacent patch small units I311...

Embodiment 2

[0042]A radar / infrared compatible stealth metasurface, starting from the conductive metal copper reflective layer 1, from bottom to top, including FR4 dielectric layer 2 and conductive thin film functional layer 3, the thickness of the conductive metal copper reflective layer 1 is 0.02mm, and the FR4 dielectric layer The thickness is 3.8mm, the real part of the relative permittivity is 5, the loss tangent value is 0.001, and the functional layer of the conductor film is a metal copper film. The large unit II32 is arranged in a 6×6 array structure according to the checkerboard structure; the large patch unit I31 is arranged in a 56×56 structure by the small patch unit I311 with a size of 0.7mm, and the large patch unit II32 is composed of small patch units with a size of 6.3mm The small patch unit II321 is arranged in an 8×8 structure, the thickness of the patch small unit I311 and the patch small unit II321 are both 0.02mm, the gap between the adjacent patch small units I311, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com