Heat dissipation device for flash lamp

A technology of heat dissipation device and flash lamp, which is applied in the direction of lighting device, cooling/heating device of lighting device, optics, etc., can solve the problem of heat transfer to the outside of the mobile terminal, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

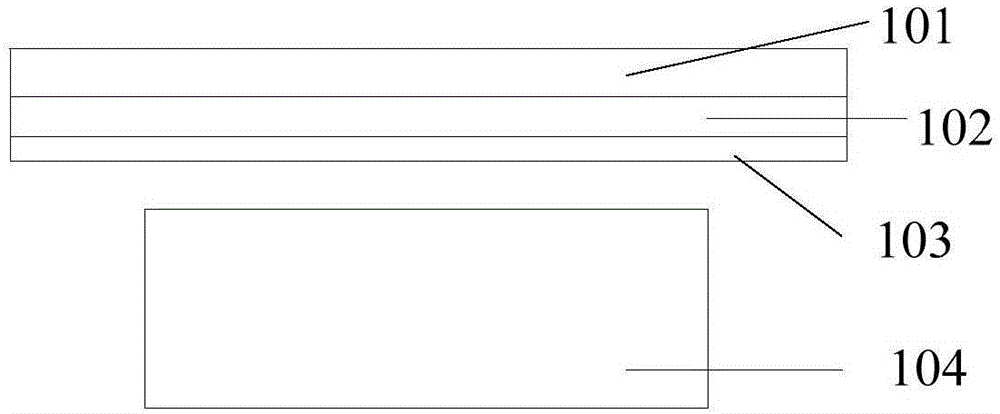

[0012] refer to figure 1 , showing a schematic structural diagram of a flashlight cooling device according to Embodiment 1 of the present invention.

[0013] The flash heat dissipation device of the embodiment of the present invention includes: a glass cover 101 , a heat dissipation layer 102 and an ink coating 103 arranged in sequence;

[0014] It should be noted that those skilled in the art can select the material of the heat dissipation layer according to actual needs, and any material with strong thermal conductivity can be used as the heat dissipation layer, which is not specifically limited.

[0015] In the specific operation process, since the thickness of the mobile terminal is fixed, the thickness of the ink coating and the thickness of the heat dissipation layer will affect the thickness of the mobile terminal, and ultimately affect the appearance of the mobile terminal. Therefore, the thickness of the ink coating and the thickness of the heat dissipation layer Not...

Embodiment 2

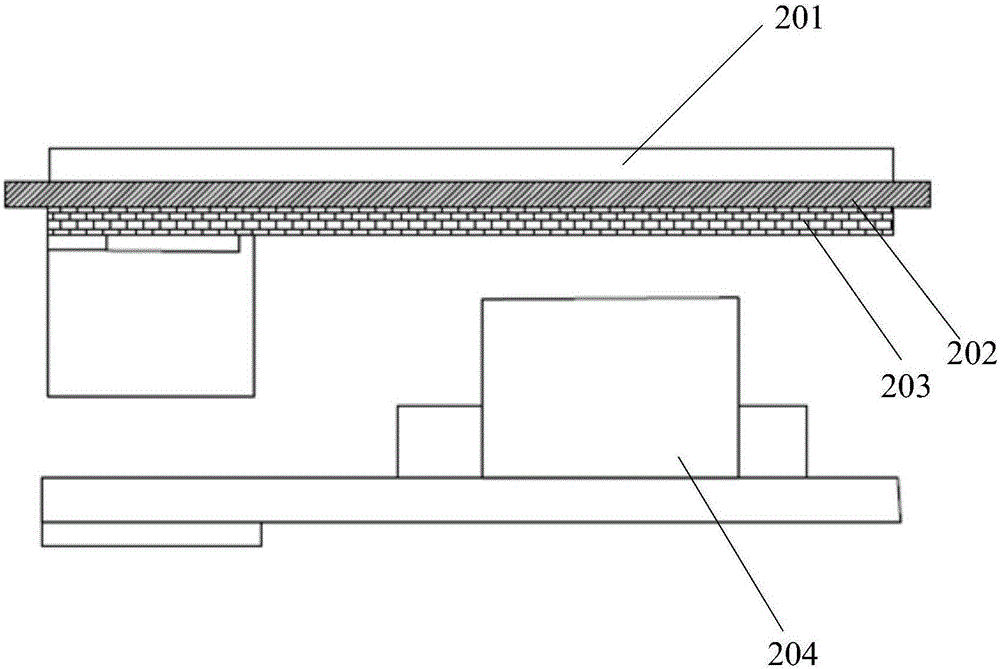

[0020] refer to figure 2 , showing a schematic structural diagram of a flashlight heat dissipation device according to the second embodiment of the present invention.

[0021] The flash heat dissipation device of the embodiment of the present invention includes: a glass cover plate 201 , a heat dissipation layer 202 and an ink coating 203 arranged in sequence;

[0022] The flash can be arranged on the front of the mobile terminal, that is, a front flash.

[0023] In the specific implementation process, the heat dissipation layer is set as a graphene layer, and the thickness is 1 μm˜10 μm.

[0024] Among them, graphene is a nano-material with mechanical properties and thermal conductivity. Its thermal conductivity is as high as 5300 / m·K. Using graphene, a new high-conductivity material, to prepare a heat dissipation layer can effectively improve the ability of thermal diffusion.

[0025] It should be noted that those skilled in the art can select the material of the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com