A single warehouse intelligent control terminal

A technology for controlling terminals and single warehouses, applied in program control, computer control, general control systems, etc., can solve the problem of not being able to grasp the grain situation of the warehouse as a whole, the upper computer being unable to collect and operating data for remote control, and the inability to achieve overall integration and associated control. and other problems to achieve the effect of data transmission and remote centralized control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

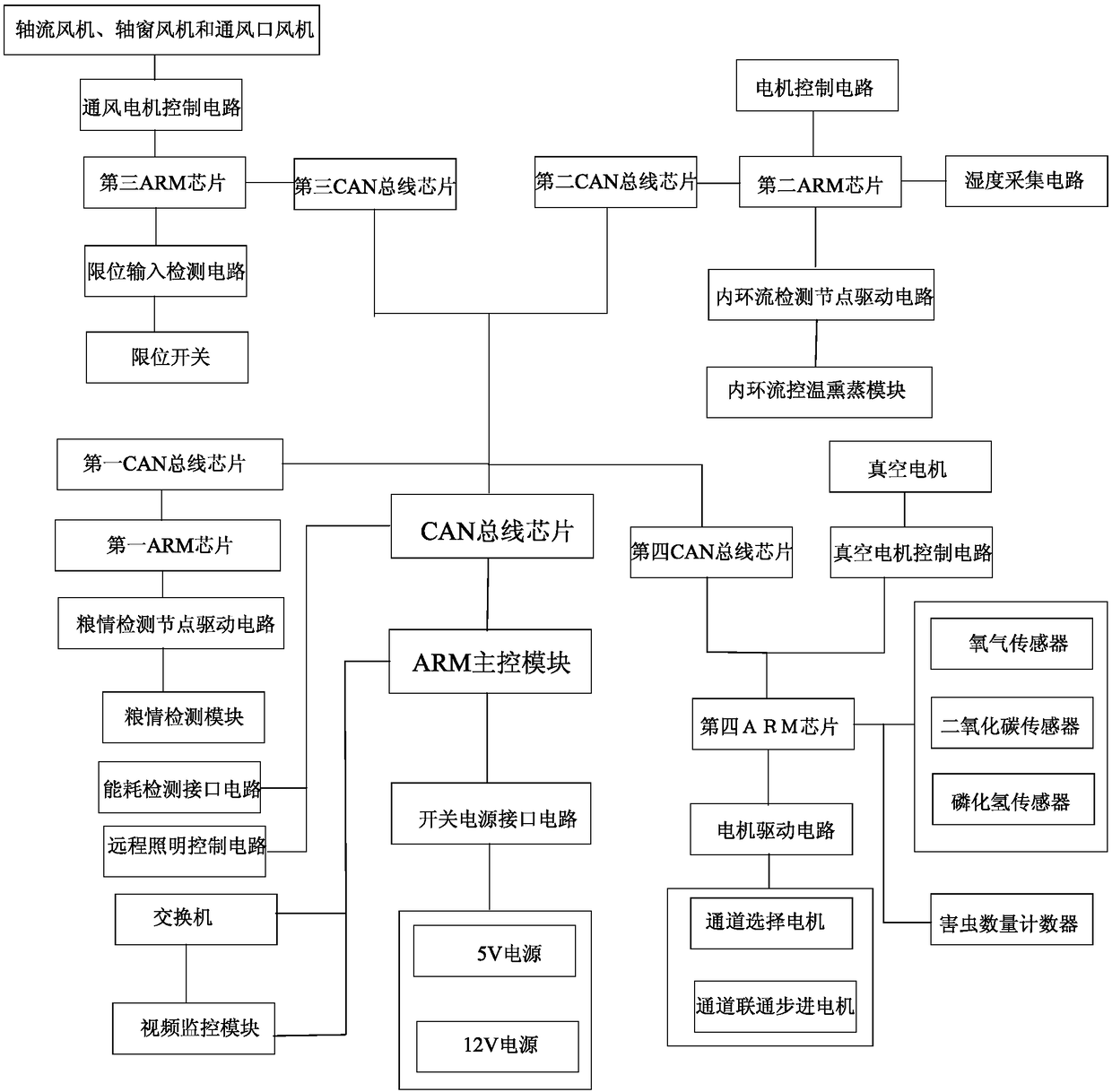

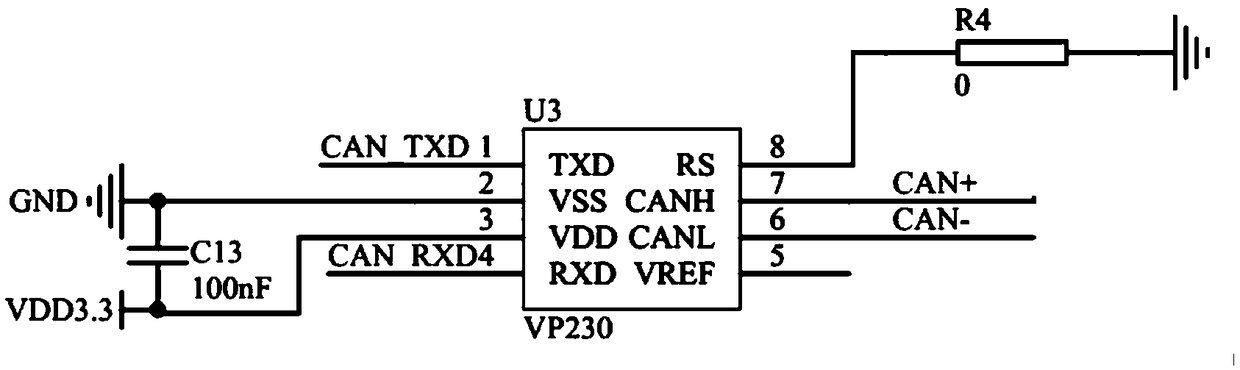

[0034] like figure 1 As shown, a single warehouse intelligent control terminal is characterized in that it includes an ARM main control module, a CAN bus chip, a switching power supply interface circuit, a grain condition detection interface circuit, and an inner circulating current detection interface circuit respectively connected to the ARM main control module. , Energy consumption detection interface circuit, pest gas detection control circuit, intelligent ventilation control circuit, remote lighting control circuit and switch.

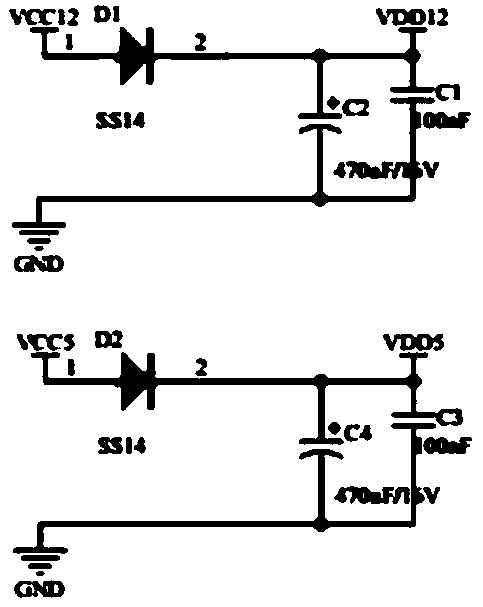

[0035] The switch receives the granary security data collected by the video monitoring module and the grain storage data collected by the inventory monitoring module. The input end of the switching power supply interface circuit is respectively connected with the 5V power supply and the 12V power supply, and the output end of the switching power supply interface circuit is connected with the power supply end of the ARM main control module.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com