Robot visual guiding system

A technology of robot vision and guidance system, applied in the field of robot vision guidance system, can solve the problems of slow device speed, slow positioning efficiency, sheet material deviation, etc., to achieve rapid adjustment, improve position accuracy and product quality, and improve correction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

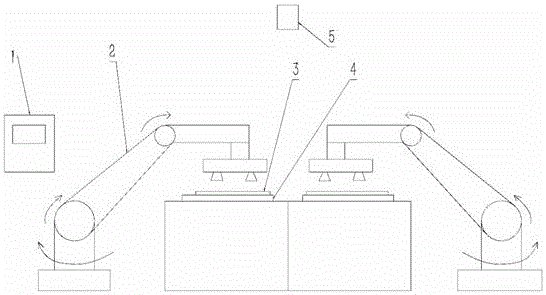

[0013] Such as figure 1 As shown, a robot vision guidance system includes a robot control system 1, a six-axis robot 2, a blank 3, a blank conveyor belt 4, and an industrial camera 5.

[0014] The robot control system 1 is composed of a PLC and a touch screen. The PLC controls the movement of the sheet conveyor belt 4, receives the image information sent by the industrial camera 5, and controls the six-axis robot to adjust the position of the sheet 3. The touch screen displays the image information captured by the industrial camera 1, selects the range of a part of the image and the difference between the actual position of the sheet 3 and the predetermined position.

[0015] There are two sheet material conveyor belts, which can realize the transportation of two sheet materials at the same time. Each blank conveyor belt is equipped with a six-axis robot 2, and the two six-axis robots are controlled by the robot control system, and the automatic adjustment of the blank positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com