Six traction device space debris net capture system

A space debris and traction device technology, applied in the aerospace field, can solve the problems of insufficient uniform size distribution of flying nets, difficulty in precise control of synchronization, poor target covering performance, etc., so as to achieve improved capture reliability and launch. The effect of fast response and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

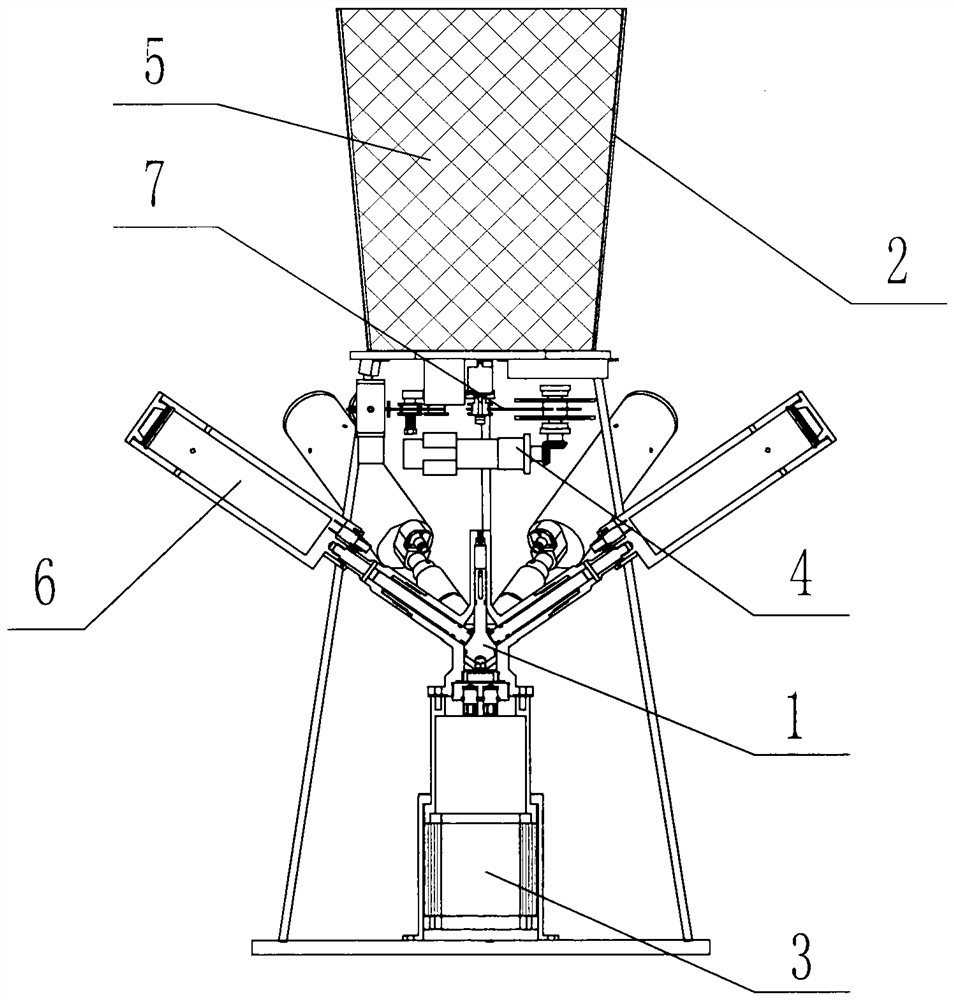

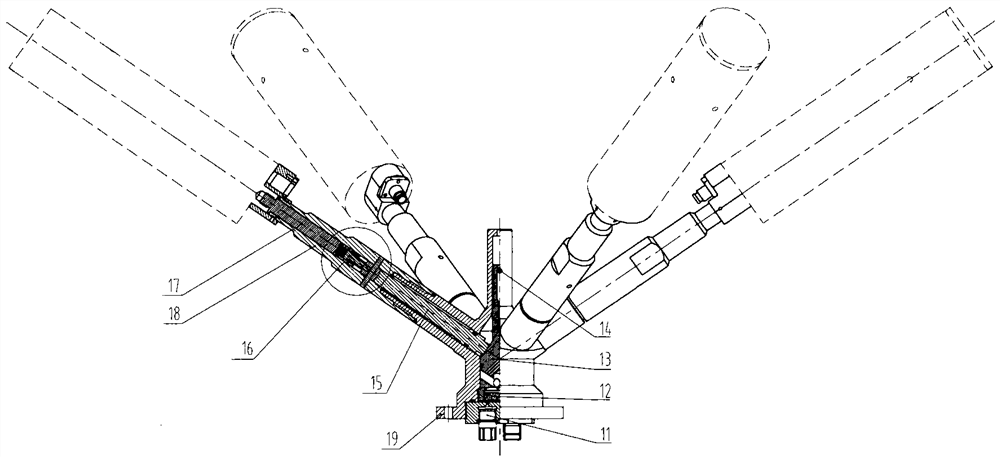

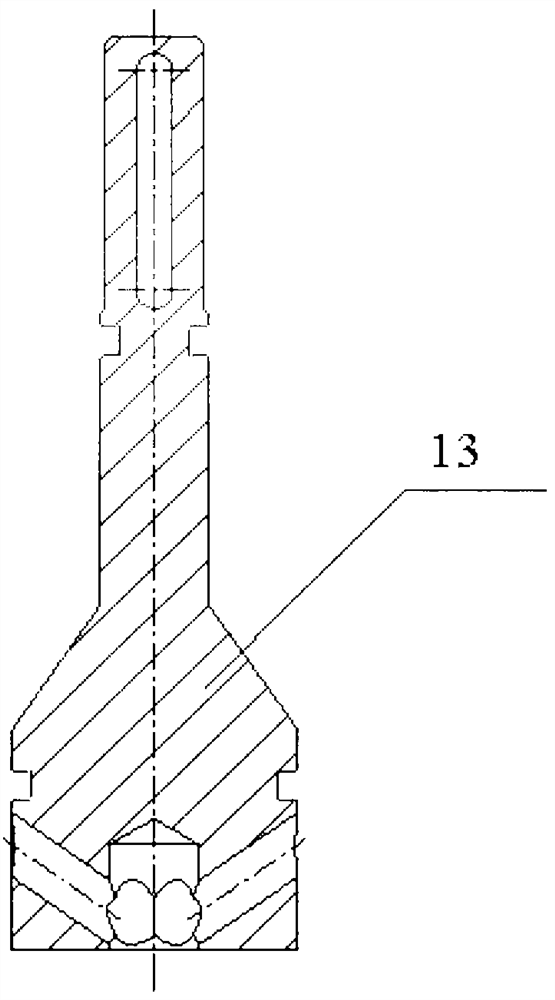

[0040] It should be understood that the space debris net capture system with six traction devices of the present invention includes a launching subsystem and a flying net subsystem, and the launching subsystem includes a launcher, a net cabin, a buffer device and a tether tension control device, and the flying net subsystem includes The rope net and the mass are determined; the transmitter pushes the six mass blocks to move according to the preset launch angle, and the mass blocks drive the rope net to be pulled out from the net cabin while unfolding and reach a fully expanded state. After reaching the target position, the net catches the target. The quality block controls the rope net to tighten the net mouth to complete the capture of the target; after the tether pulls the captured target out of orbit, the tether cutter cuts the tether to separate the target from the satellite platform. The invention adopts the one-stage launch and six-mass synchronous launch methods and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com