Method for separating and preparing electronic grade nitrous oxide from medical grade nitrous oxide

An electronic-grade, nitrous oxide technology, applied in the directions of nitrous oxide, nitrogen oxides/oxyacids, etc., can solve the problems of unsatisfactory adsorption capacity and selectivity, and achieve no solvent volatilization and loss, high selectivity, The effect of large absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

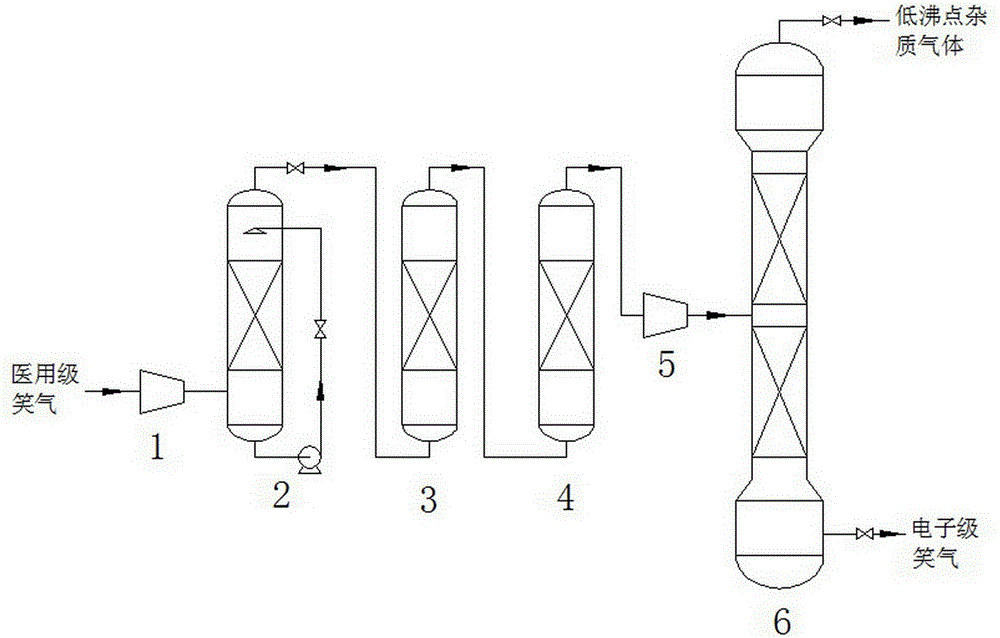

[0021] combined with figure 1 A method of separating and preparing electronic grade nitrous oxide from medical grade nitrous oxide in the method of the present invention is as follows: the first gas compressor (1) will contain N 2 O accounts for the medical grade laughing gas that volume fraction is 99% and is compressed to the pressure of 0.3 MPa, is then transported to the inlet of spray absorption tower (2) and is positioned at bottom side by pipeline; The tower top temperature setting of spray absorption tower (2) At 40°C, the medical grade laughing gas flowing from bottom to top will contact the trihexyltetradecylphosphonium methionine ionic liquid in the tower, thereby removing most of the CO in the medical grade laughing gas 2 、H 2 O, NO, NO 2 , and then enter the drying tower (3) through the upper outlet through the pipeline; in the drying tower (3), the medical grade laughing gas flowing from bottom to top will contact with the silica gel in the tower, thereby remov...

Embodiment 2

[0023] combined with figure 1 A method of separating and preparing electronic grade nitrous oxide from medical grade nitrous oxide in the method of the present invention is as follows: the first gas compressor (1) will contain N 2 O accounts for the medical grade laughing gas that volume fraction is 99% and is compressed to the pressure of 0.5 MPa, is then transported to the inlet of spray absorption tower (2) and is positioned at bottom side by pipeline; The tower top temperature setting of spray absorption tower (2) At 70°C, the medical grade nitrous oxide flowing from bottom to top will contact the trihexyltetradecylphosphonoproline ionic liquid in the tower, thereby removing most of the CO in the medical grade nitrous oxide 2 、H 2 O, NO, NO 2 , and then enter the drying tower (3) through the upper outlet through the pipeline; in the drying tower (3), the medical grade laughing gas flowing from bottom to top will contact with the silica gel in the tower, thereby removing ...

Embodiment 3

[0025] combined with figure 1 A method of separating and preparing electronic grade nitrous oxide from medical grade nitrous oxide in the method of the present invention is as follows: the first gas compressor (1) will contain N 2 O accounts for the medical grade laughing gas that volume fraction is 99% and is compressed to the pressure of 0.4 MPa, is then transported to the inlet of spray absorption tower (2) and is positioned at bottom side by pipeline; The tower top temperature setting of spray absorption tower (2) At 60°C, the medical grade nitrous oxide flowing from bottom to top will contact the trihexyltetradecylphosphonium methionine ionic liquid in the tower, thereby removing most of the CO in the medical grade nitrous oxide 2 、H 2 O, NO, NO 2 , and then enter the drying tower (3) through the upper outlet through the pipeline; in the drying tower (3), the medical grade laughing gas flowing from bottom to top will contact with the silica gel in the tower, thereby rem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap