Charging device of in-situ treatment of polluted bottom sludge

An in-situ treatment and feeding device technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as poor sludge treatment effect, save power consumption, reduce Dependence on electricity and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

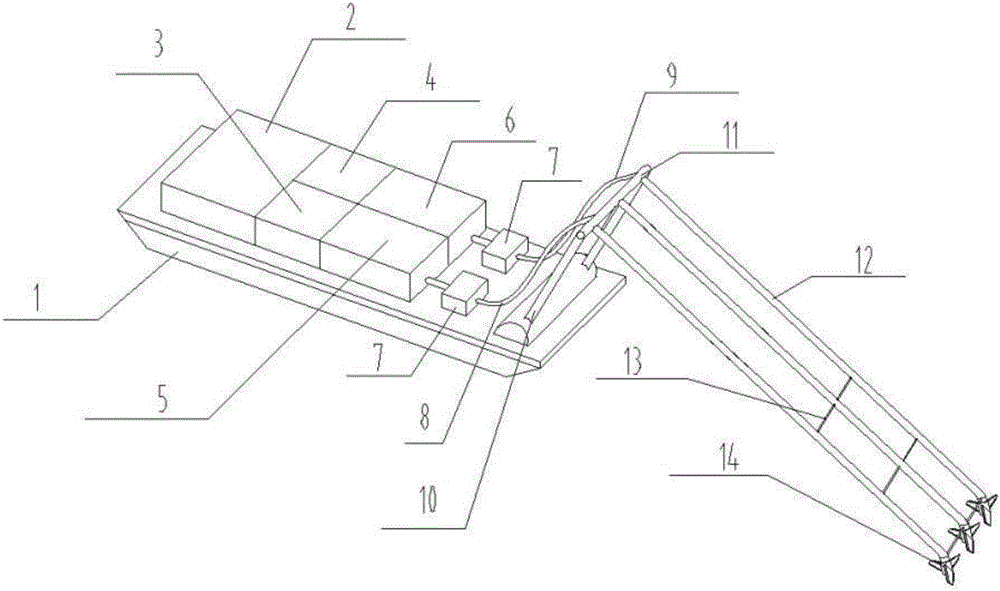

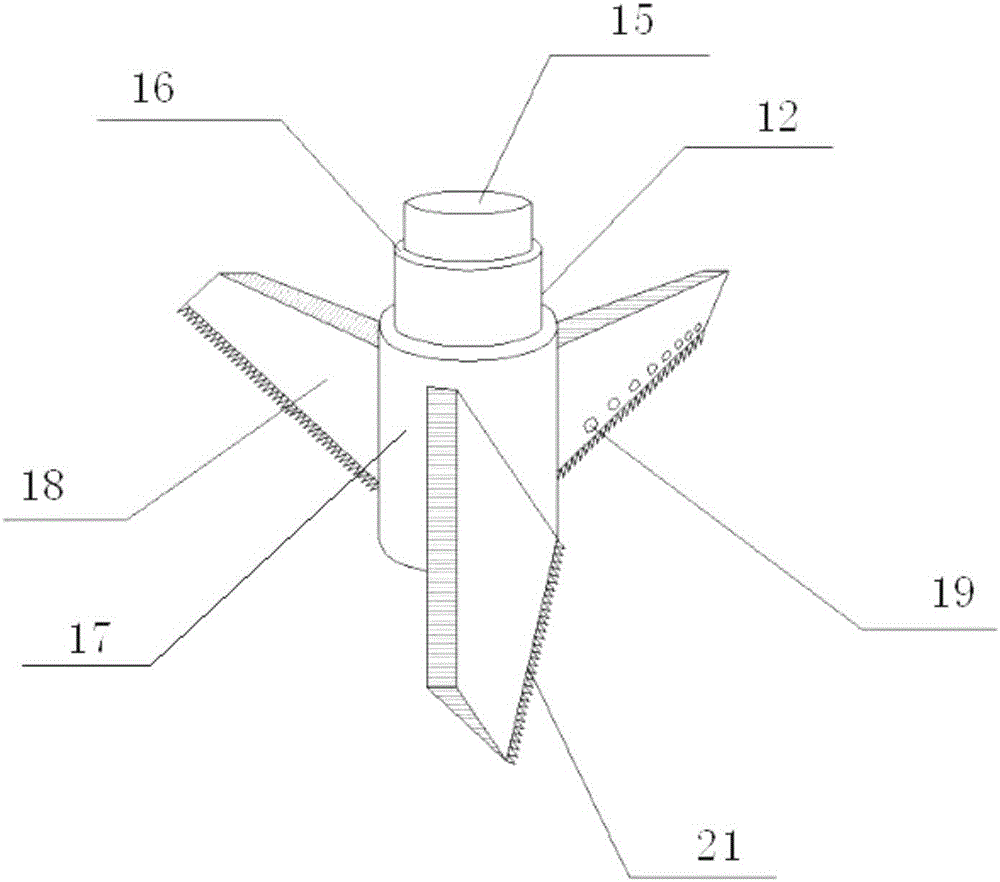

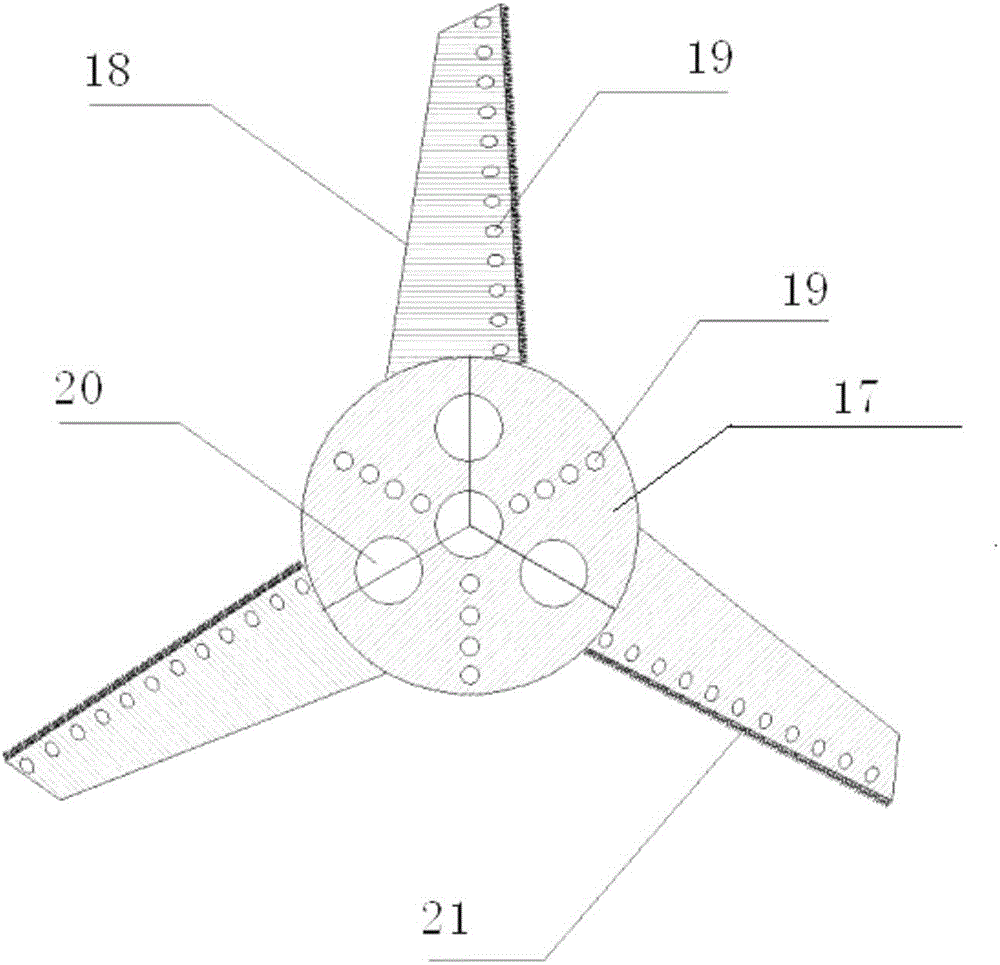

[0026] figure 1 , figure 2 , image 3 The feeding device for in-situ treatment of polluted sediment shown in the figure includes the hull, feeding main pipe, feeding branch pipe, and a hollow mixing head that can discharge materials. The hull is equipped with a central control machine room, a chemical feeding box, and a solid material feeding box. Frequency conversion pump, concrete pump, mechanical arm, the feeding main pipe is connected with the mechanical arm, and the main feeding pipe includes the main pipe for medicament feeding and the main pipe for solid material feeding. Connection, the solid material feeding box is connected to the main material conveying main pipe through the concrete pump and the second connecting pipe in turn. The frequency conversion pump, concrete pump and mechanical arm are respectively connected to the central control machine room. One end of each feeding branch pipe is connected to the main feeding pipe, and the other end of each feeding br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com