Radiation cross-linked flame-retardant coating composition for cables

A radiation crosslinking and composition technology, which is applied in the field of radiation crosslinking flame retardant coating composition, can solve the contradiction between mechanical properties and flame retardant properties, formula composition and thermal aging properties, antioxidant system and radiation crosslinking effect. Contradictions and other problems, to achieve the effect of excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adjust the control voltage of the front and back rolls of the double roll to 150V, keep it for 1 hour, increase the roll temperature to 130°C, add 40 parts by weight of EVA1 (base resin, VA content of 15%) and 20 parts by weight of EVA2 (base resin, The VA content is 30%) and the smelting is started for about 1 minute, and then 40 parts by weight of magnesium hydroxide are added for smelting for about 3 minutes, and then the sheet is pulverized with a pulverizer to obtain a flame-retardant masterbatch.

[0025] Add basic resins such as flame retardant masterbatch and EVA into a high-speed mixer, add a small amount of white oil, stir for about 15 seconds, and then add thiophenol antioxidant-1# (from Great Lakes Company, USA), fully stir and discharge the material, add The molten sensitizer is stirred evenly.

[0026] Add uniformly mixed materials into the extruder, and control the barrel temperature of the extruder to: 1800°C (feeding port), 220°C, 225°C, 220°C, 210°C (head),...

Embodiment 2

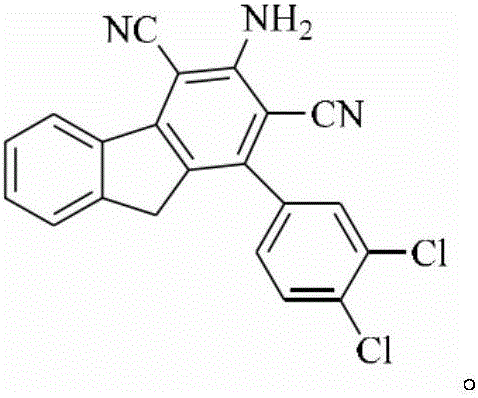

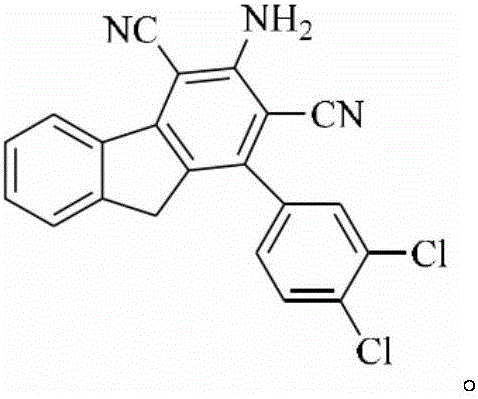

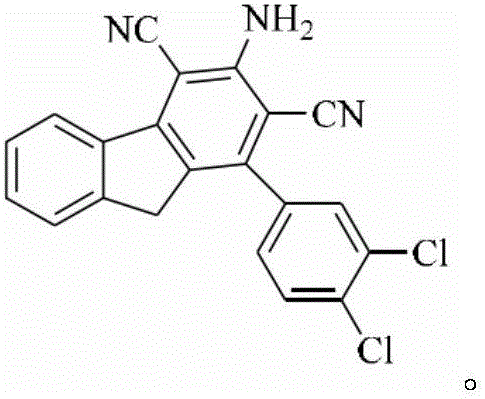

[0031] A radiation crosslinked flame-retardant coating composition was prepared in the same manner as in Example 1, except that no radiation crosslinked sensitizer was used, and the radiation crosslinked sensitizer had the following structure:

[0032]

[0033] Then use the same method to test. As a result, the oxygen index was less than 23, the tensile strength was 18.4, and the elongation at break was 570%. The temperature resistance of the sample is poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com