Sintered ore cooling method adopting pre-sintering

A cooling method and a technology of sintering, which are applied in the field of iron and steel metallurgy, can solve the problems that there is no direct and effective way to improve the cooling efficiency of the ring cooler, and achieve the effects of quality improvement, ring cooling efficiency, and power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

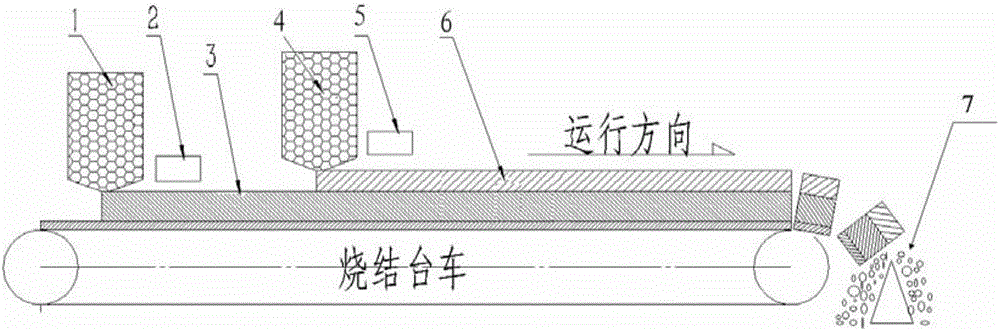

Image

Examples

Embodiment 1

[0015] During the pre-sintering production of the belt roaster, the thickness of the first cloth layer is 500mm, the thickness of the second cloth layer is 200mm, the total thickness of the material layer is 700mm, and the pre-sintering time is 10min. It is installed at the end of the belt roaster. There is a sinter separation device. During the unloading process of the whole trolley, the sinter hits the separation device. The sinter with red fire layer is about 250mm, which is less than or equal to 1 / 2 of the thickness of the total material layer. The about 250mm thick sinter with red fire layer and the temperature ≥ 600°C are separated from the remaining 450mm thick sinter. At the bottom, the red-hot high-temperature sinter is distributed to the upper part of the low-temperature sinter for ring cooling.

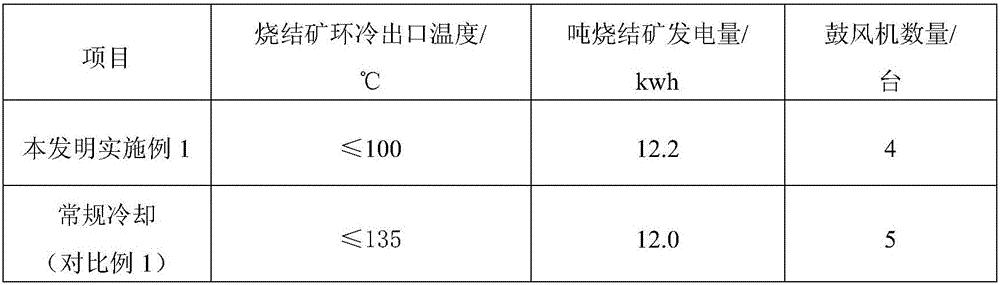

[0016] When the operating speed of the annular cooler is constant, the main production results are compared in Table 1.

[0017] Table 1 Comparison of production results ...

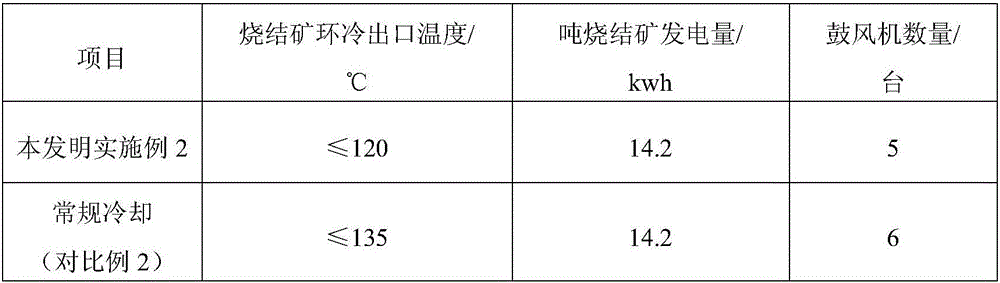

Embodiment 2

[0020] During the pre-sintering production of the belt roaster, the thickness of the first cloth layer is 650mm, the thickness of the second cloth layer is 300mm, the total thickness of the material layer is 950mm, and the pre-sintering time is 14min. It is installed at the tail discharge of the belt roaster There is a sinter separation device, and the separation device is 200mm away from the grate bar of the sintering trolley for unloading. During the unloading process of the whole trolley, the sintered ore hits the separation device, and the sintered ore with the red fire layer is about 450mm, which is less than or equal to 1 / 2 of the thickness of the total material layer. The about 450mm thick sinter with glow layer and temperature ≥ 400°C is separated from the remaining 500mm thick sinter, and after being broken by small crushers respectively, the low-temperature sinter without glow is distributed at the bottom of the ring cooler , The red-hot high-temperature sinter is di...

Embodiment 3

[0025] During the pre-sintering production of the belt roaster, the thickness of the first cloth layer is 700mm, the thickness of the second cloth layer is 400mm, the total thickness of the material layer is 1100mm, and the pre-sintering time is 25min. It is installed at the tail discharge of the belt roaster There is a sinter separation device, and the separation device is 250mm away from the unloading sinter trolley grate. During the unloading process of the whole trolley, the sintered ore hits the separation device, and the sintered ore with the red fire layer is about 500mm, which is less than or equal to 1 / 2 of the thickness of the total material layer. The about 500mm thick sinter with red hot layer and temperature ≥ 900°C is separated from the remaining 600mm thick sinter, and after being broken by small crushers respectively, the low-temperature sinter without red hot is distributed at the bottom of the ring cooler , The red-hot high-temperature sinter is distributed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com