High-efficiency non-doped ultra-thin light-emitting layer thermally activated delayed fluorescence organic light-emitting diode and its preparation method

A thermal activation delay, light-emitting diode technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components and other directions, can solve the problems of material difficulties, device preparation process difficulty, device preparation process difficulty, etc., and achieve suppression of quenching. quenching effect, significant external quantum efficiency, and the effect of reducing the difficulty of device fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

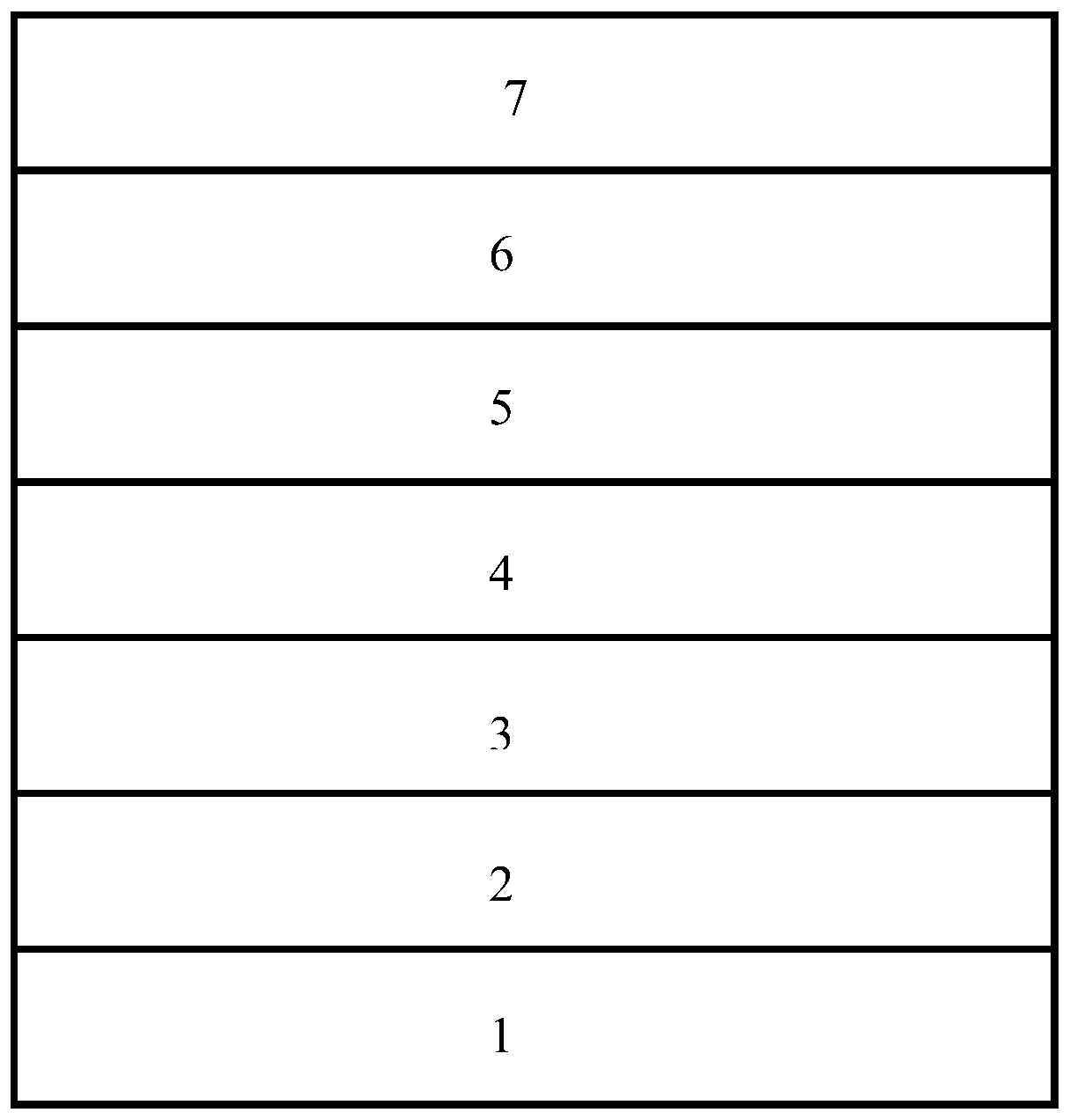

[0046] Such as figure 1 As shown, the high-efficiency non-doped ultra-thin light-emitting layer thermally activated delayed fluorescence organic light-emitting diode of this embodiment is composed of substrate 1, anode 2, hole transport layer 3, exciton isolation layer 4, light-emitting layer 5, Electron transport layer 6 and cathode 7 constitute.

[0047] Take a 15-20Ωsq covered with a 95nm thick sheet resistor -1 Indium tin oxide (ITO) glass substrate. First, thoroughly clean the substrate, and ultrasonically clean it in isopropanol, tetrahydrofuran, micron-sized conductive glass washing liquid, deionized water (resistivity greater than 18MΩ), deionized water, and isopropanol in an ultrasonic machine. Steps Sonicate for at least 10 minutes. Then dry it thoroughly in an electric blast drying oven to remove residual solvent on the surface. Then ionized oxygen treatment was carried out for 20 minutes to remove the pollutants on the ITO surface, improve the work function of ...

Embodiment 2

[0056] The preparation process was the same as in Example 1, wherein the non-doped ultra-thin light-emitting layer material was replaced by p-ACR-SO, and the thicknesses were 0.08, 0.1, 0.2, 0.4, 0.8, 1.2 nm. The obtained device structure is: ITO(95nm) / TAPC(30nm) / CBP(25nm) / p-ACR-SO(0.08, 0.1, 0.2, 0.4, 0.8, 1.2nm) / TmPyTB(55nm) / LiF(1nm) / Al (100nm). The corresponding conventional doped and undoped device structures are: ITO (95nm) / TAPC (30nm) / CBP:10%p-ACR-SO (25nm) / TmPyTB (55nm) / LiF (1nm) / Al (100nm ); ITO(95nm) / TAPC(30nm) / p-ACR-SO(25nm) / TmPyTB(55nm) / LiF(1nm) / Al(100nm).

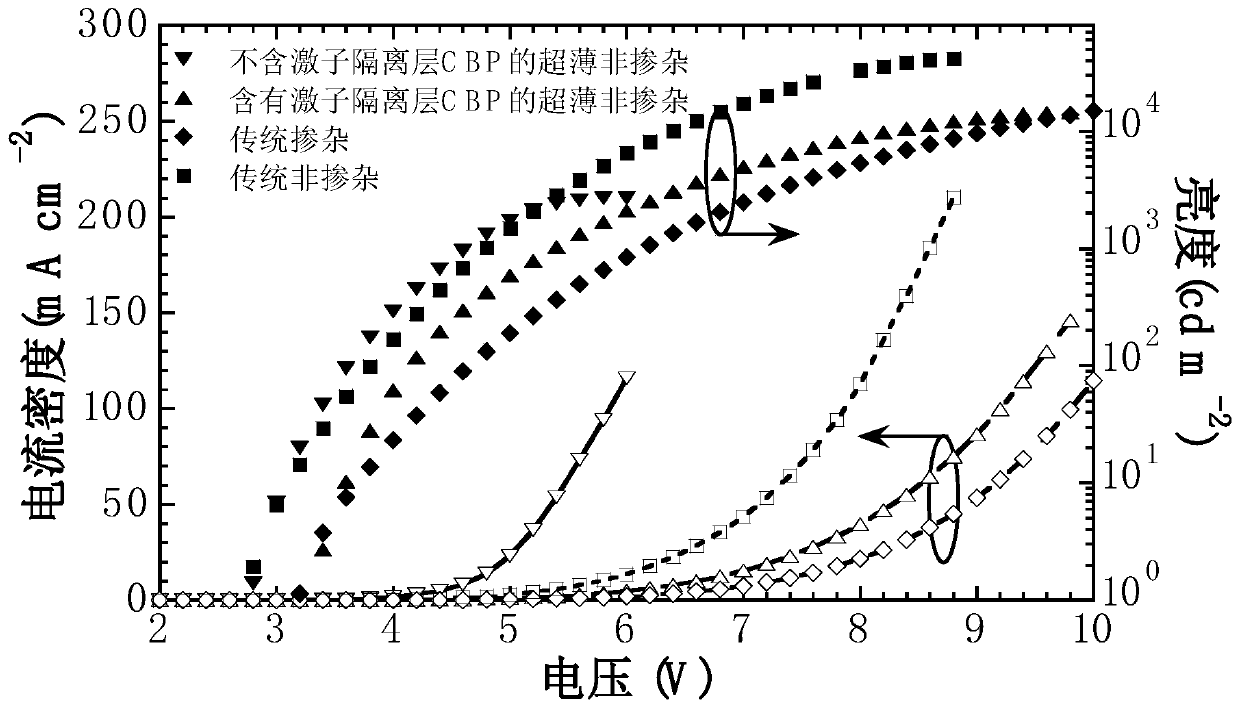

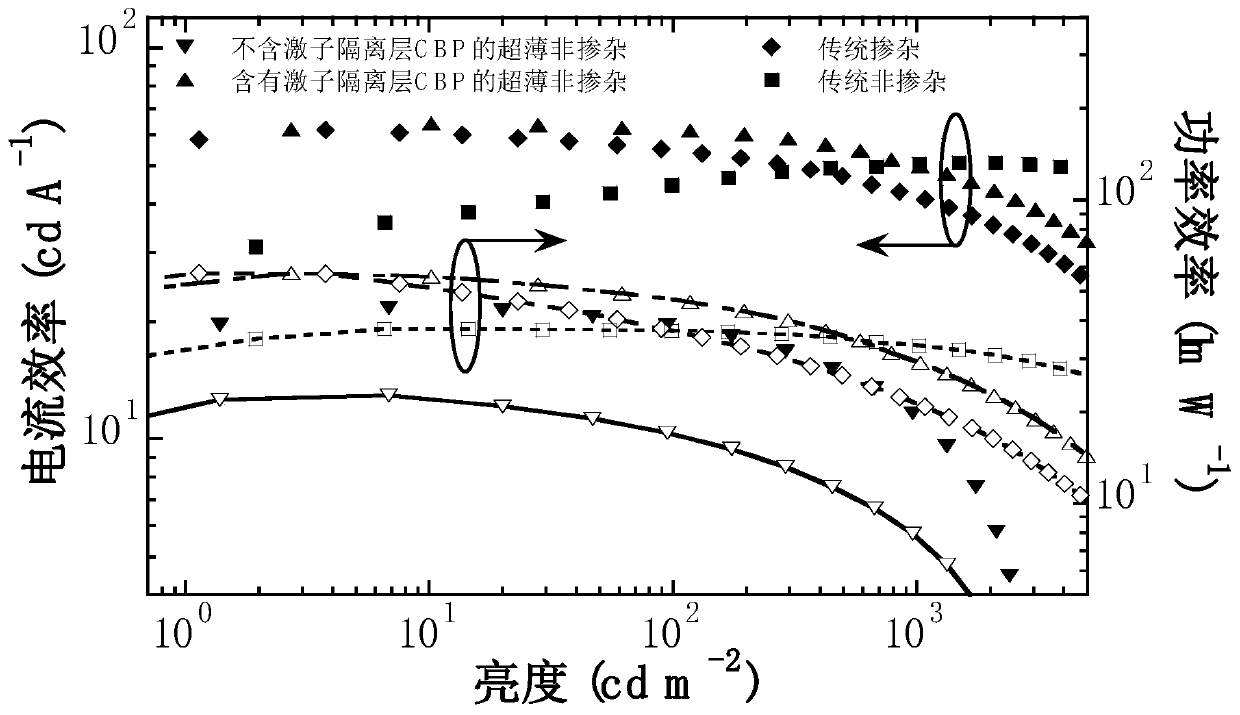

[0057] The current density-brightness-voltage characteristic curve, current efficiency-brightness-power characteristic curve efficiency diagram, and external quantum efficiency-brightness characteristic curve diagram of the above-mentioned three types of devices obtained in this embodiment are shown in Figure 7-9 shown.

[0058] Table 2 is a summary table of performance data of devices with different non-do...

Embodiment 3

[0062] The preparation process was the same as in Example 1, wherein the material of the non-doped ultra-thin light-emitting layer was replaced by TZ-SBA, and the thicknesses were 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8 nm. The exciton isolation layer was replaced by DEEPO with a thickness of 2nm. A hole blocking layer mCP and an electron blocking layer DPEPO are simultaneously introduced. The resulting device structure is: ITO(95nm) / TAPC(30nm) / mCP(10nm) / DPEPO(2nm) / TZ-SBA(0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8nm) / DPEPO(10nm) / TmPyTB(40nm) / LiF(1nm) / Al(100nm). The corresponding traditional doped and undoped device structures are: ITO (95nm) / TAPC (30nm) / mCP (10nm) / DPEPO:20% TZ-SBA (30nm) / DPEPO (10nm) / TmPyTB (40nm) / LiF(1nm) / Al(100nm); ITO(95nm) / TAPC(30nm) / mCP(10nm) / TZ-SBA(30nm) / DPEPO(10nm) / TmPyTB(40nm) / LiF(1nm) / Al(100nm ). In addition, in order to ensure that the overall thickness of the comparison device is consistent, the doped and non-doped device structures with the same thickness a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com