Etchant composition for metal layer containing silver or silver alloy

A technology of silver alloy and composition, applied in the field of etching liquid compositions containing etching regulators, can solve problems such as wiring short circuit, excessive etching, increase in etching deviation, etc., and achieve the effects of improving etching unevenness and maintaining etching deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 15 and comparative example 1 to 8

[0082] According to the component content disclosed in the following Table 1, each component was mixed to manufacture the etchant composition containing the silver or silver alloy metal film of Examples 1-15 and Comparative Examples 1-8.

[0083] 【Table 1】

[0084]

[0085]

[0086] The meanings of abbreviated terms used in the above tables are as follows.

[0087] IDA: iminodiacetic acid, DA: diacetic acid, EDTA: ethylenediaminetetraacetic acid, DTPA: diethylenetriaminepentaacetic acid, McA: malic acid, SA: succinic acid, TA: tartaric acid, LA: lactic acid, GA : glutaric acid, CA: citric acid, MA: malonic acid, Oz: oxalic acid.

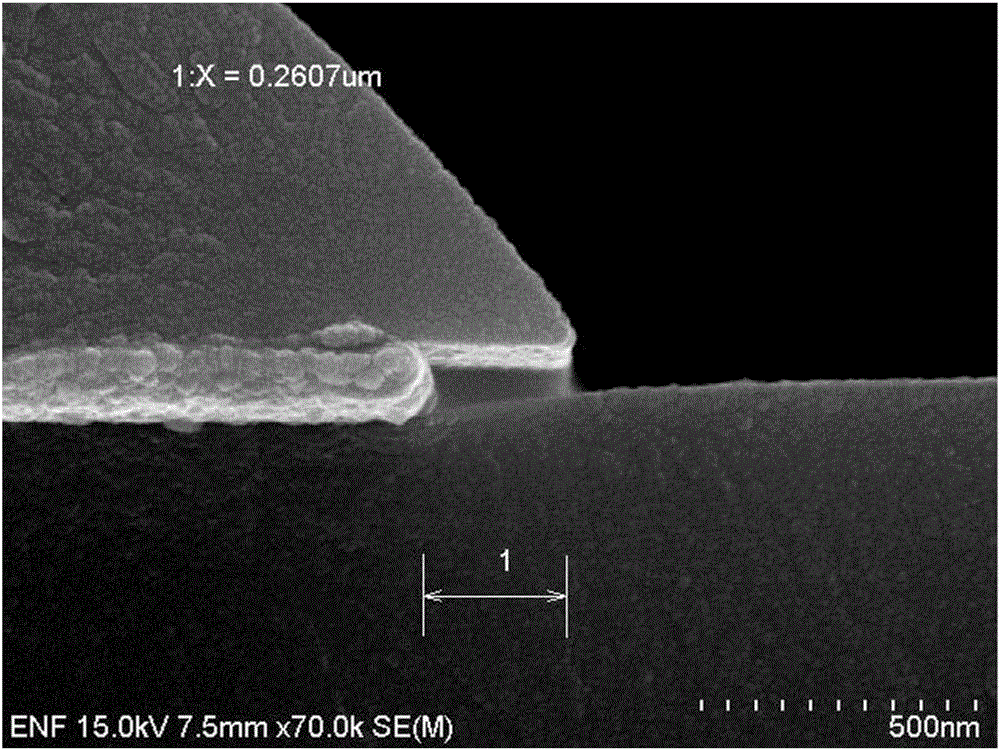

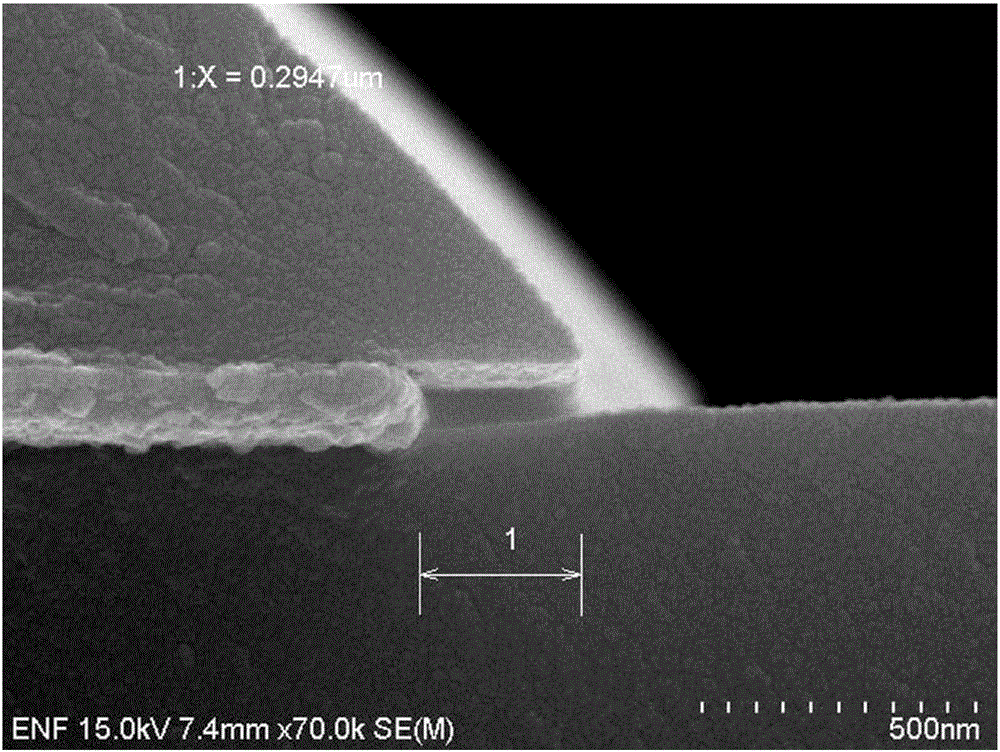

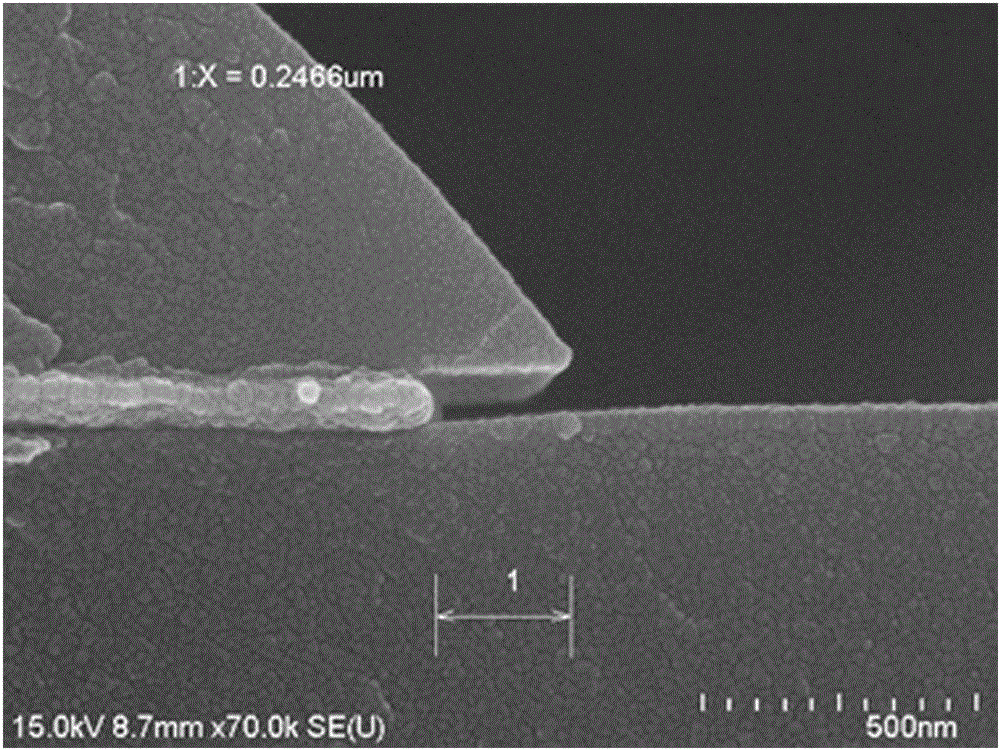

[0088] on a glass substrate with a thickness of and and After depositing the three layers of indium tin oxide-silver or silver alloy film-indium tin oxide respectively, a photolithography process is performed to form a pattern, thereby manufacturing a test piece. The aforementioned silver alloy film refers to a silver-copper-palladium a...

experiment example 1

[0089] Experimental example 1: Evaluation of etching characteristics as the number of pieces processed increases

[0090] Measure etch bias (CD bias) with silver powder addition. The aforementioned etching deviation means that the size of the photoresist pattern formed on the substrate is smaller than the size of the mask pattern.

[0091] In order to carry out the evaluation in the above-mentioned Experimental Example 1, using the etching solution composition provided in the above-mentioned Examples 1 to 15 and Comparative Examples 1 to 8, in a sprayable device (Mini-etcher ME-001), at 40 ° C Under the conditions of 120 seconds of etching.

experiment example 2

[0092] Experimental example 2: Evaluation of the time until a wiring short-circuit occurs

[0093] The time at which a short circuit occurred in the wiring was measured according to the etching process time. The above evaluation was carried out by measuring the change in etching characteristics with the time of jetting in a jetting device (Mini-etcher ME-001).

[0094] In order to carry out the evaluation of the above-mentioned Experimental Example 2, using the etching solution compositions provided in the above-mentioned Examples 1 to 15 and Comparative Examples 1 to 8, in a sprayable device (Mini-etcher ME-001), at 40°C Etching was carried out for 12 hours.

[0095] Table 2 shows the results of Experimental Examples 1 and 2.

[0096] 【Table 2】

[0097]

[0098]

[0099] As shown in the results of Experimental Example 1 shown in Table 2 above, for Examples 1 to 15 comprising the etching solution composition provided by the present invention, when carrying out the etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com