Tray and anchor system for underground coal mine anchor rod supporting

A bolt support and pallet technology, which is applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problems of damage to the bolt body, affecting the strength of the bolt support, and insufficient pre-tightening force. The effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

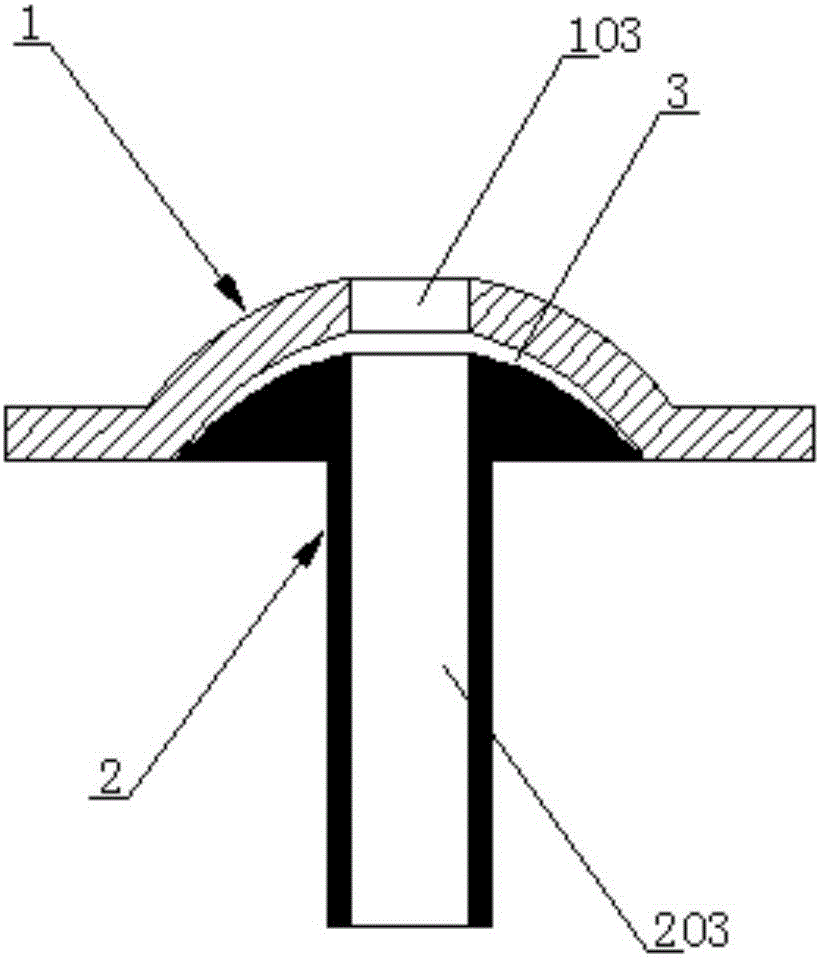

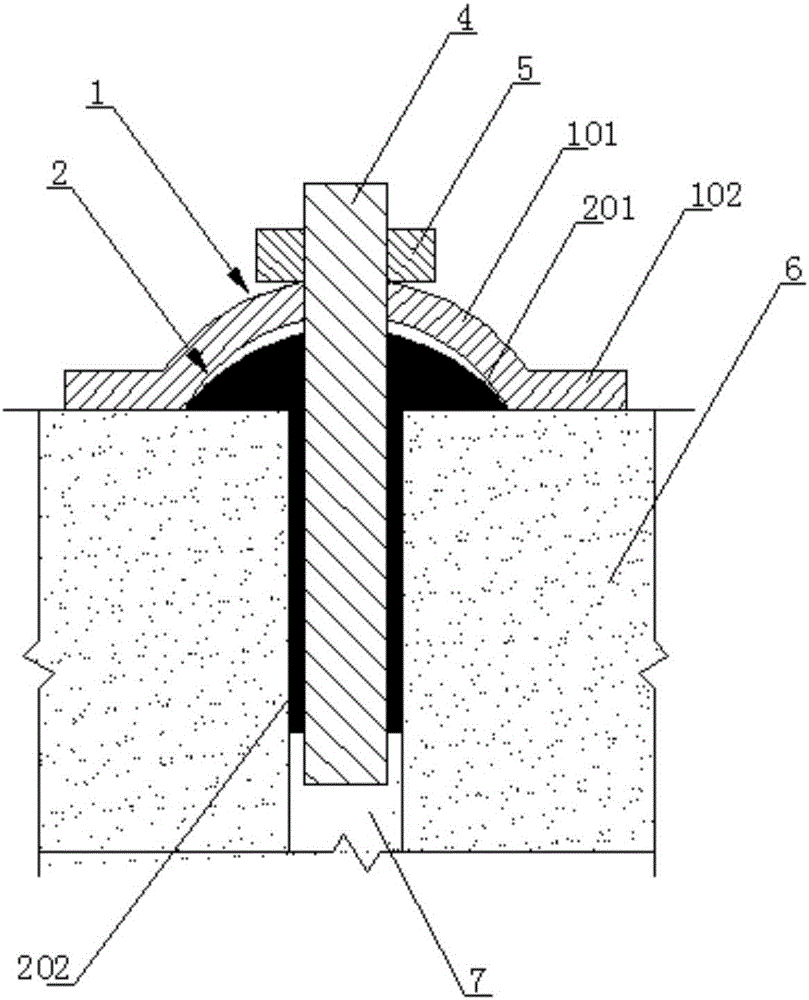

[0029] The pallet used for bolt support in coal mines includes a pallet back layer 1 and a pallet belly layer 2; the pallet back layer 1 includes a pallet back bulge 101, a pallet back flattened portion 102 and a pallet back anchor Through hole 103; the tray web 2 includes a tray web bulge 201, a tray web cylinder 202 and a tray web anchor rod through hole 203; the manufacturing material of the tray back layer 1 is steel, and the tray Abdominal layer 2 manufacture material is rubber.

[0030] In this embodiment, the raised portion 101 of the back layer of the tray is arc-shaped, and the tray cavity 3 is formed between the upper end surface of the raised portion 201 of the belly layer of the tray and the lower end surface of the raised portion 101 of the back layer of the tray; When carrying out support, the lower end surface of the flat part 102 of the back layer of the tray is in full contact with the end surface of the anchoring rock mass 5, and the lower end surface of the ...

Embodiment 2

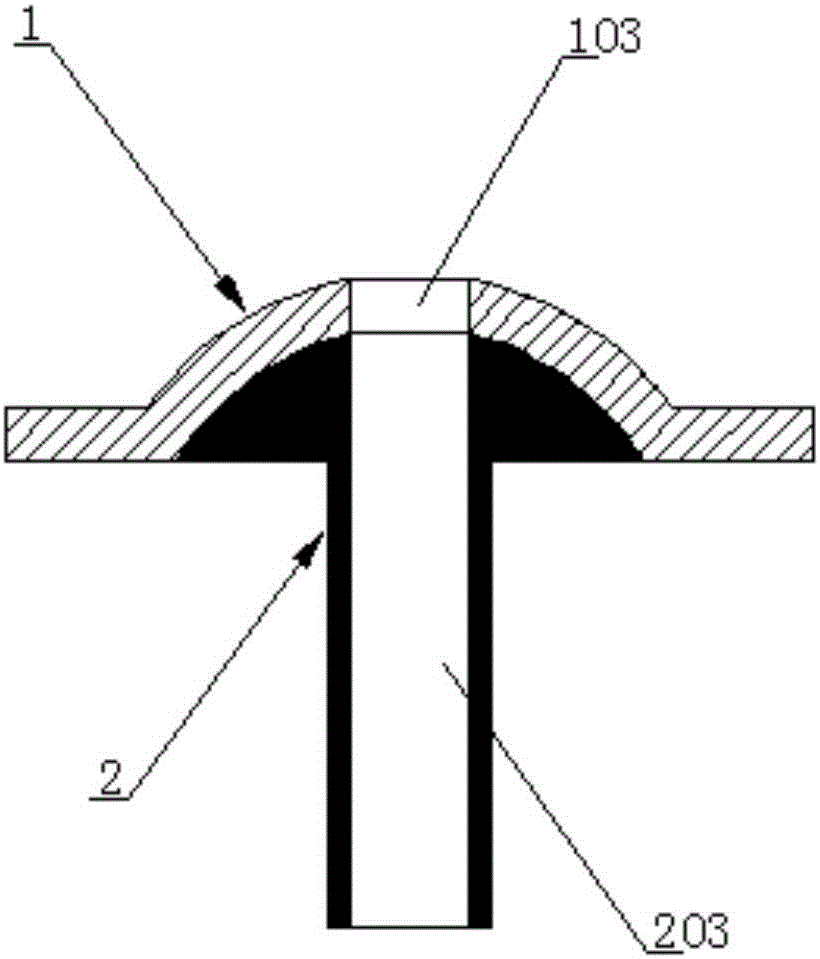

[0037] Compared with Embodiment 1, this embodiment has the same technical characteristics except the following technical characteristics:

[0038] The pallet back bulge 101 is arc-shaped, and the upper end surface of the tray belly bulge 201 is in full contact with the lower end surface of the tray back bulge 101; when supporting, the pallet back is flat The lower end surface of the portion 102 is in full contact with the end surface of the anchoring rock mass 6, and the lower end surface of the raised portion 201 of the belly layer of the tray is also in full contact with the end surface of the anchoring rock mass 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com