Airspace-engine test-bed long-range exhaust system

An aerospace engine and exhaust system technology, which is applied in the field of aviation and aerospace engine testing, can solve the problems of difficulty in meeting the requirements of large-flow and long-range testing of engines, short engine testing time, and large plant floor area, saving testing sites, Conducive to environmental protection and small investment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to meet the requirements of the long-distance exhaust test process of the engine, the gas mixture of several kilograms to several hundred kilograms in the test chamber can be discharged smoothly per second, so that the vacuum degree of the test chamber can always be maintained within the required range. The invention provides an aerospace engine. The long-distance exhaust system of the test bench has the ability to realize the direct connection test of the engine for more than 3000s and the free jet test for more than 350s.

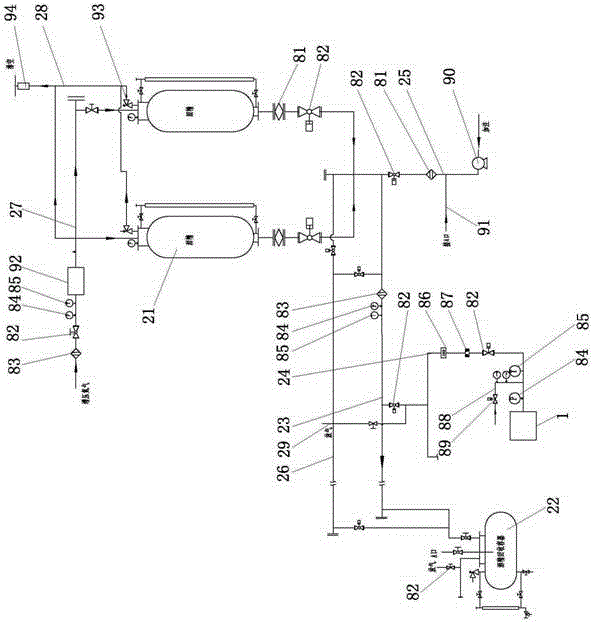

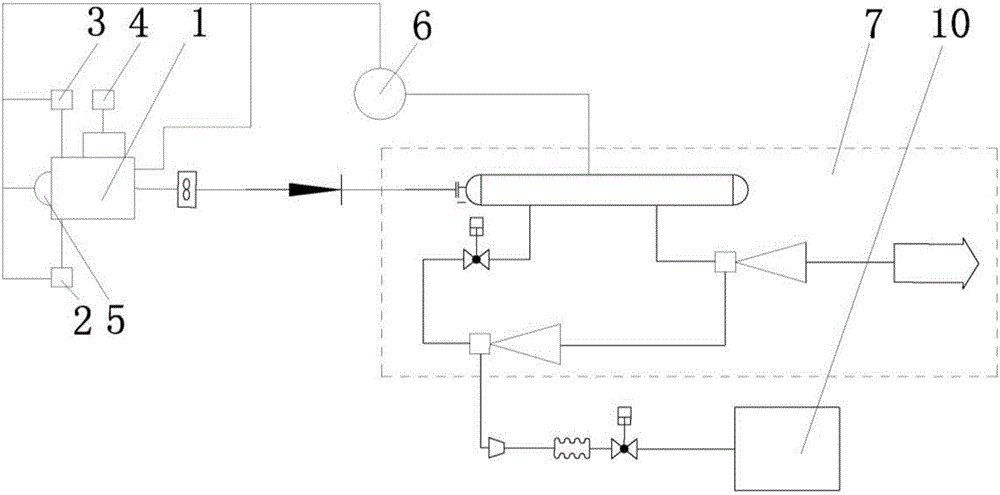

[0061] like figure 1 and figure 2 As shown, the system includes a steam generator 1, an alcohol supply system 2, a liquid oxygen supply system 3, a demineralized water supply system 4, a plasma igniter 5, a gas distribution system 6 and a steam injection system 7;

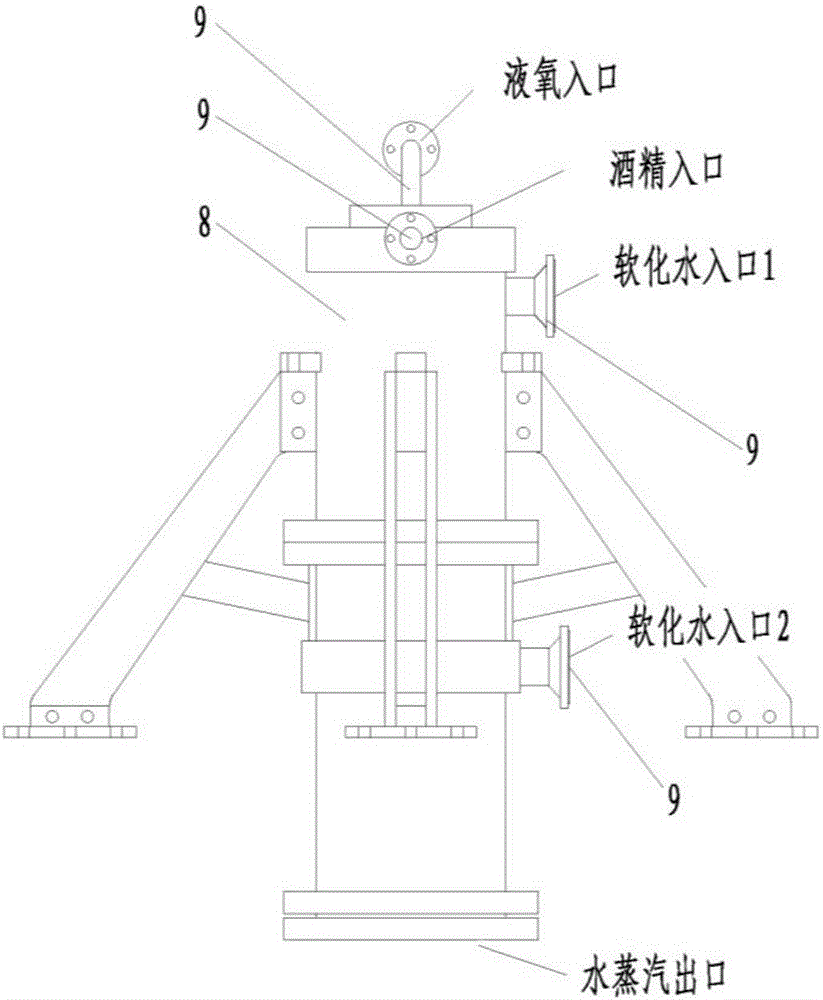

[0062] The steam generator 4 includes a straight cylinder 8 and four medium pipelines 9 installed on the straight cylinder 8; the four medium pipelines 9 include alcohol pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com