High temperature gas valve

A gas valve, high temperature technology, applied in the direction of sliding valve, multi-way valve, valve device, etc., can solve the problems that are difficult to meet aerospace vehicles, long response time of gas valve, valve stem stop working, etc., to improve safety guarantee, The overall weight is reduced to meet the effect of maneuvering

Inactive Publication Date: 2012-04-18

LINQUAN AEROSPACE MOTOR CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a long time, the valve body has been made of high-temperature alloy and the use of two electromagnets to control the gas valve has caused problems: the gas valve is large in size and heavy in weight; the response time of the gas valve is long, and the response time of the electromagnet is generally tens of milliseconds; When the gas enters the valve body, the medicine residue in the gas is easy to remain in the valve body. In severe cases, the valve stem will stop working, causing the gas valve to fail.

These problems have always been difficult to solve

Existing technologies are difficult to meet the maneuverability, flexibility, and higher precision requirements of aerospace vehicles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

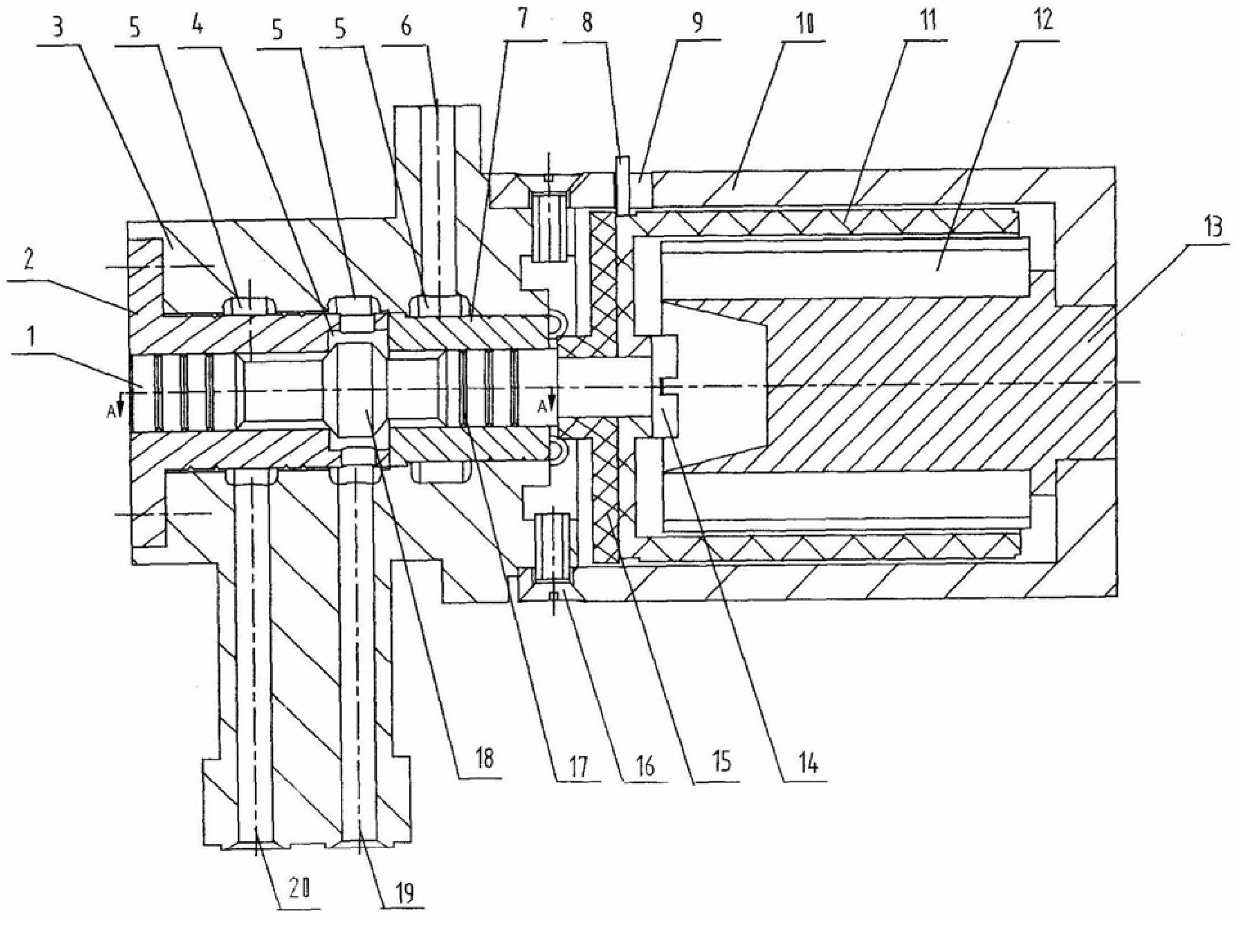

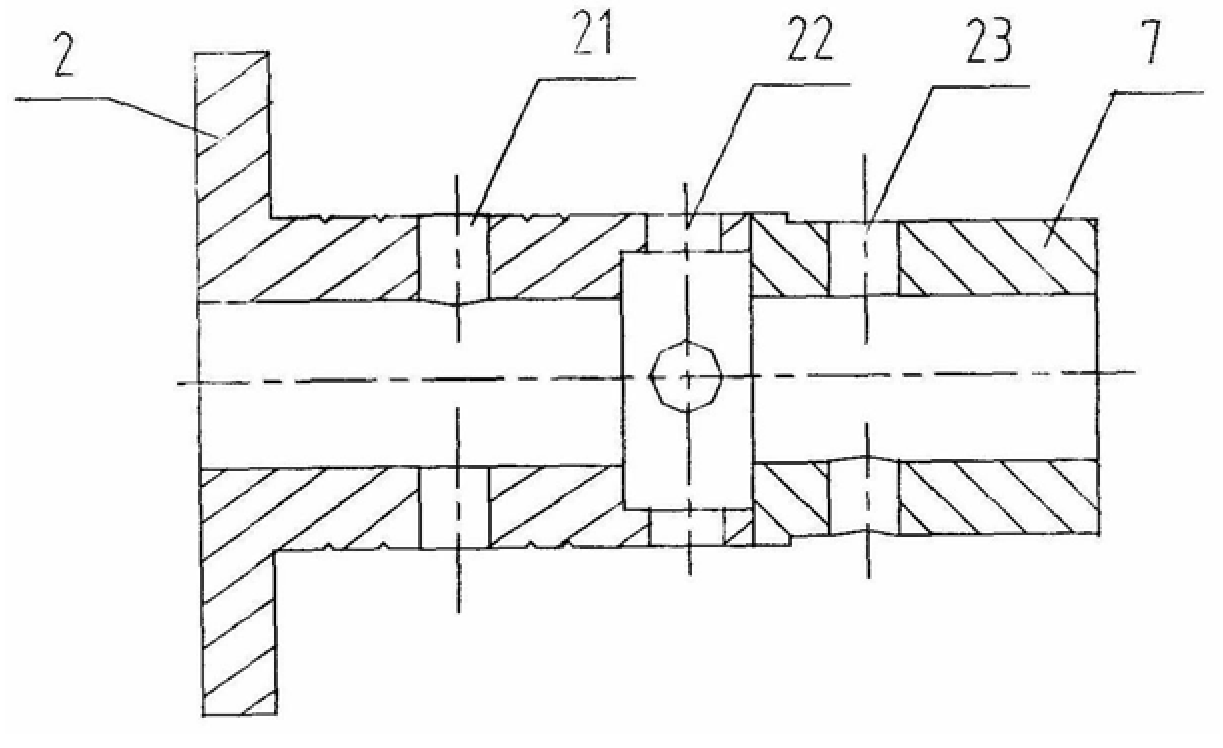

The invention discloses a high-temperature gas valve, which relates to the technical field of attitude and track control of aerospace vehicles. The attitude of the aircraft can be adjusted to enter a proper flight track through the control of the valve. By applying power to the linear motor in the forward or reverse direction, the moving coil drives the valve stem to move forward and backward, so as to control the movement of the balance ball head on the valve stem in the split cavity to form the left or right chamber. When the left chamber is connected to the high-pressure gas exhaust channel, high-pressure gas enters the exhaust channel from the left chamber and is discharged; when the right chamber is connected to the high-pressure gas channel, high-pressure gas enters from the right chamber through the jet channel working status. The control system can adjust the intake of high-pressure gas according to the flight status of the aircraft, so that the attitude of the aircraft can enter the proper flight track in a short period of time. The invention has the characteristics of small size, fast response and easy control, can meet the maneuverability, flexibility and high-precision requirements of aerospace vehicles, and improves safety guarantee.

Description

High temperature gas valve technical field The invention relates to the technical field of attitude and orbit control of an aerospace vehicle, in particular to a miniature high-temperature gas valve. The high-temperature gas can be controlled by the valve to adjust the attitude of the aircraft to enter a proper flight track. Background technique At present, the high-temperature gas valves used in many types of aerospace vehicles generally adopt the scheme of high-temperature alloy plus electromagnet. When the gas valve is in use, the temperature of the gas passing through the gas valve is very high, about 1000 ℃ ~ 1400 ℃, the adverse effects of high temperature gas must be considered in the design and manufacture. For a long time, the valve body has been made of high-temperature alloy and the use of two electromagnets to control the gas valve has caused problems: the gas valve is large in size and heavy in weight; the response time of the gas valve is long, and the respon...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16K3/00F02K9/58F16K11/078

Inventor 黄敬军郑泽明郑柳英田胤蓬李和飞

Owner LINQUAN AEROSPACE MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com