Punching assembly of plastic film production system

A technology of plastic film and production system, applied in the field of plastic film, can solve the problems that the size, shape, spacing and number of rows of holes cannot be adjusted in production, the quality of hole forming needs to be improved, the labor intensity is high, etc. High efficiency, low labor intensity and uniform hole formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

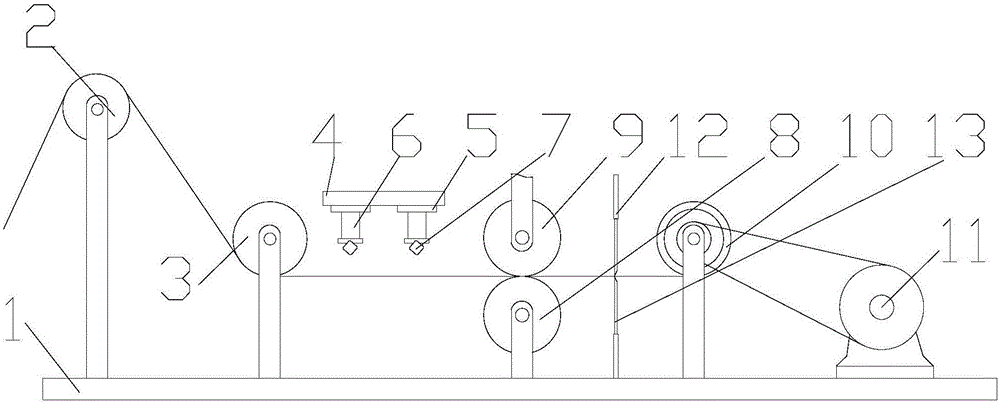

[0011] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a punching assembly of a plastic film production system proposed by the present invention.

[0012] refer to figure 1 , the perforating assembly of a kind of plastic film production system that the present invention proposes, comprises frame 1, is provided with discharge roller 2 on frame 1, is provided with laser punching mechanism on the discharge side of discharge roller 2, discharge roller and Guide roller 3 is arranged between described laser punching mechanism, and described laser punching mechanism comprises hanging mechanism 4, and hanging mechanism 4 is provided with at least two groups of punching assemblies, and described punching assembly includes slide block 5, Support bar 6 and laser puncher 7, slide block 5 can be horizontally slidably arranged on the hanging mechanism 4, and is driven by the first driving device to move left and right, support bar 6 is slidably arranged on slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com