cam key

A positioning key and cam technology, which is applied to metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems affecting the positioning accuracy and repeat positioning accuracy, the force of the pin shaft and the rigidity of the transmission, and the accuracy of the attachment milling head. To meet the requirements and other issues, to achieve the effect of compact structure, good positioning accuracy and repeat positioning accuracy, cutting rigidity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

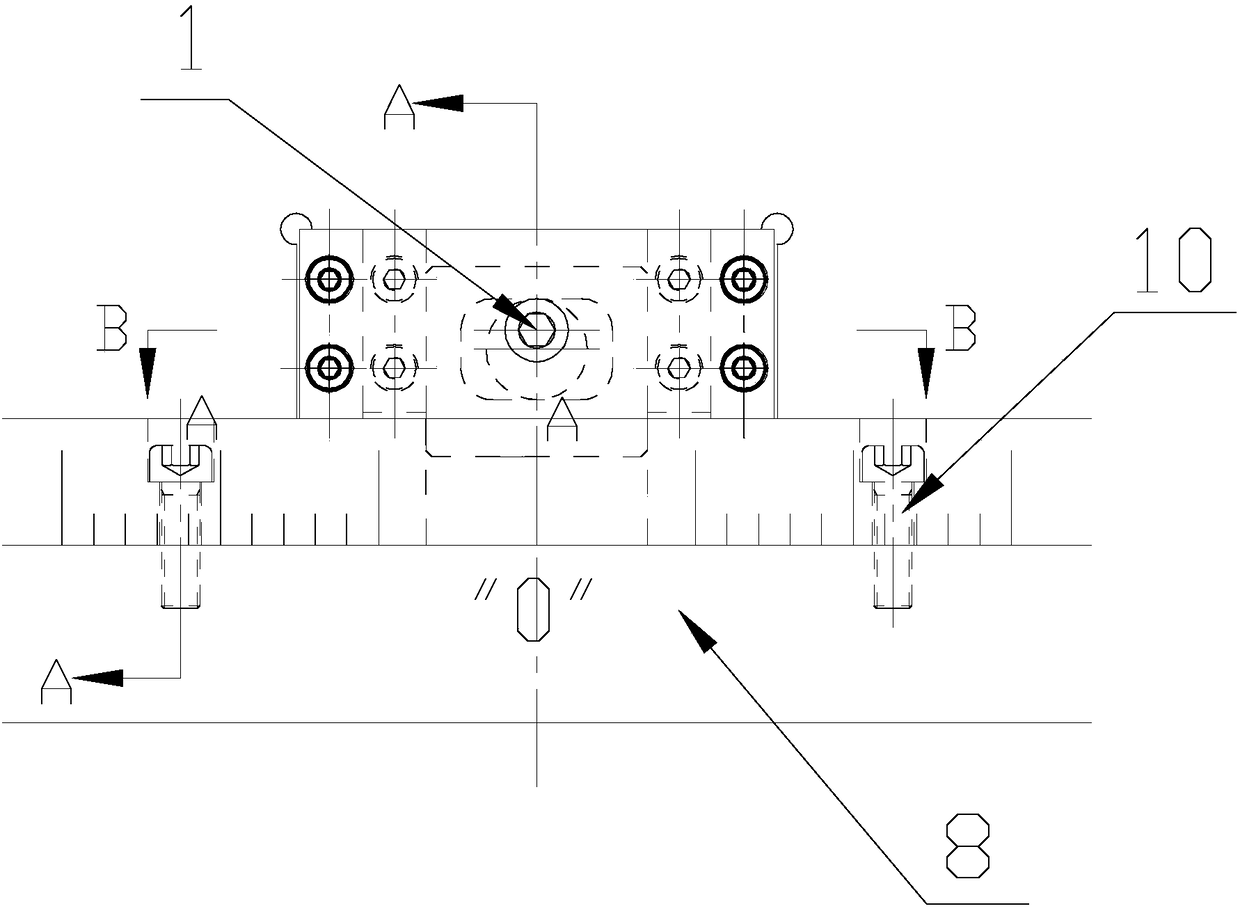

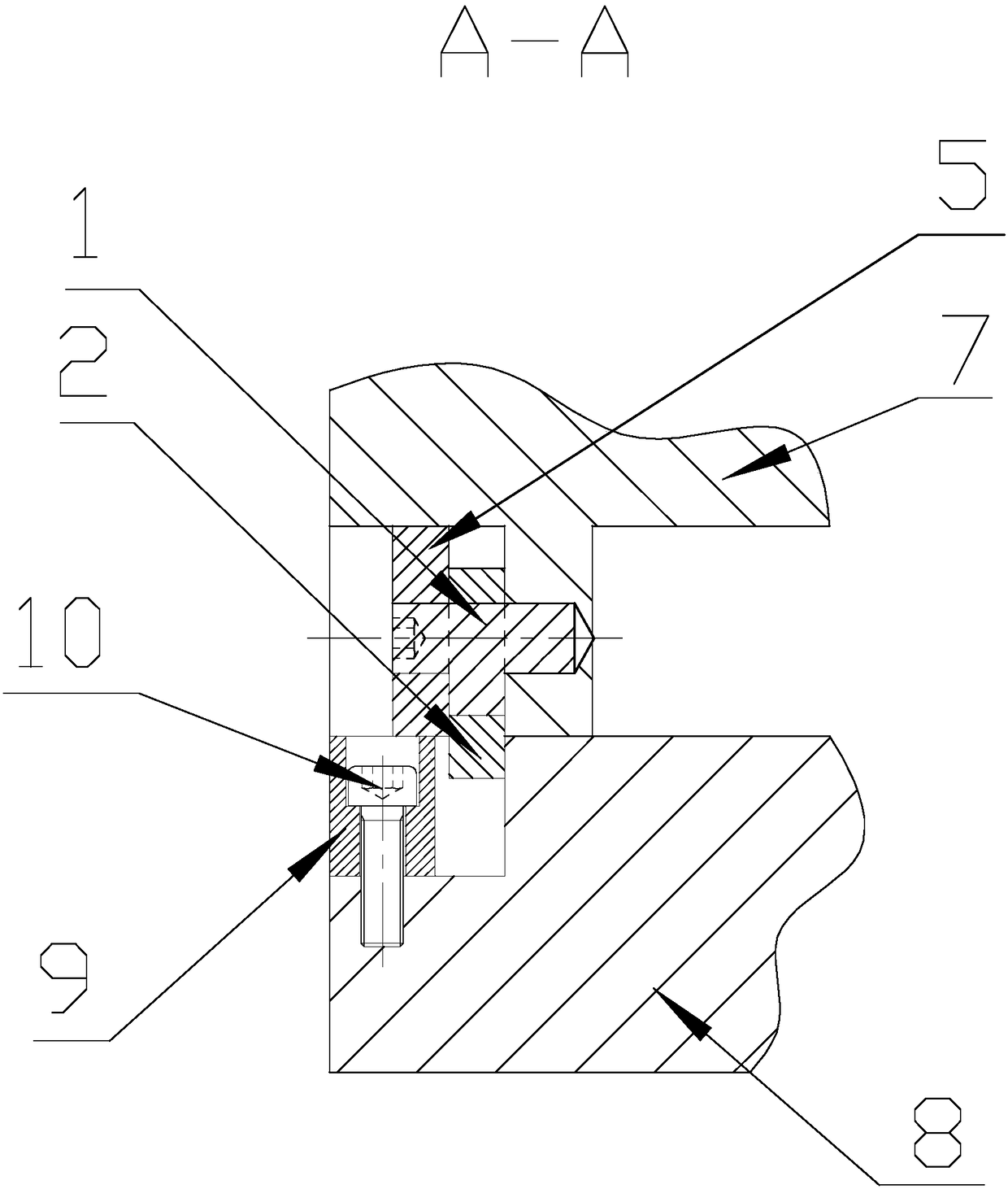

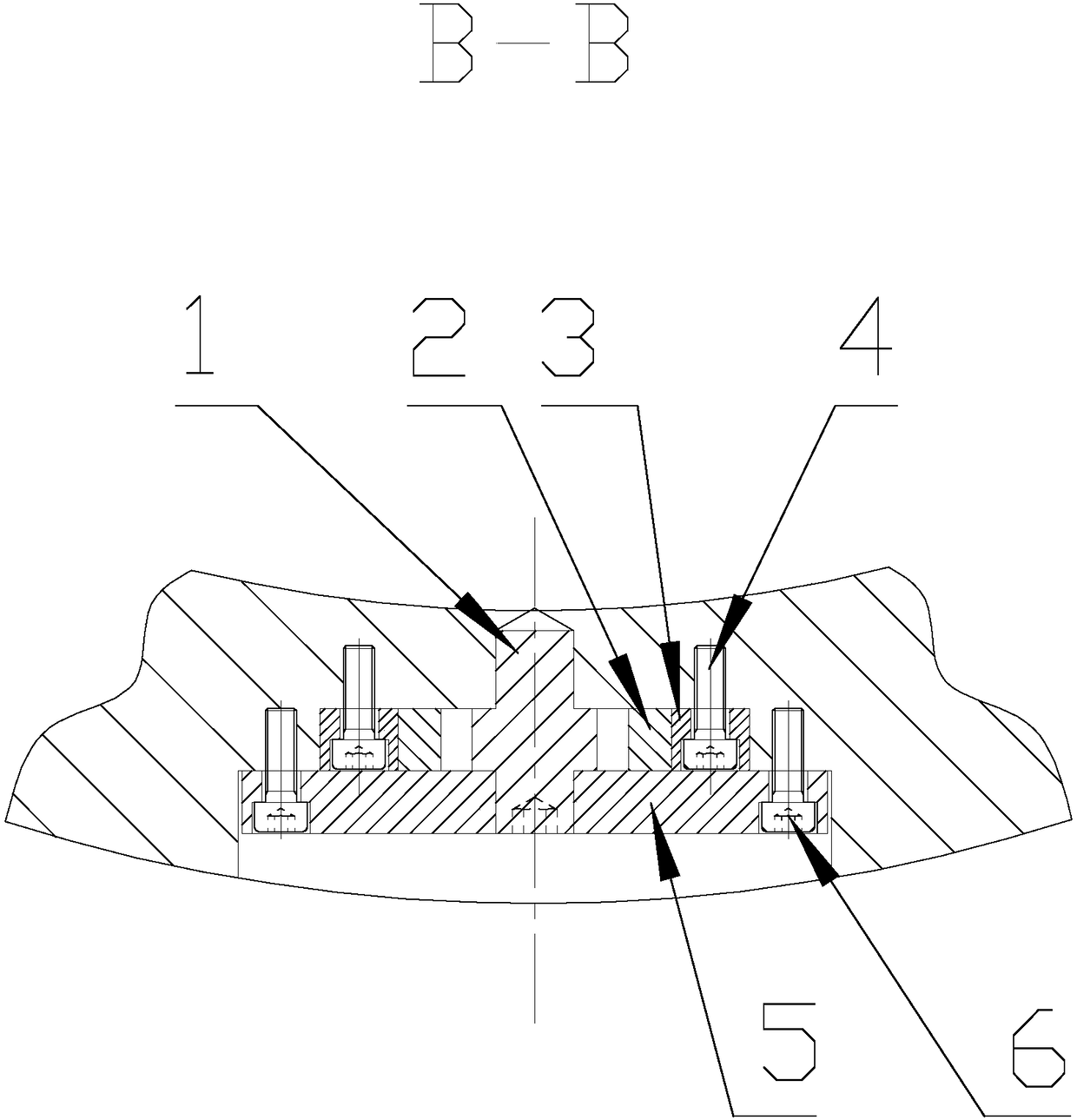

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a cam positioning key includes an upper rotary body 7, a cam, a stopper 3, a pressure plate 5, a hollow positioning key 2 and a lower rotary body 8, and the stopper 3 is fixedly connected to the upper rotary body 7 by screws 4 Above, the pressing plate 5 is fixedly connected to the upper rotating body 7 through screws 6, the cam has an eccentrically arranged camshaft 1, one end of the camshaft 1 is fixedly connected to the upper rotating body 7, and the other end is fixedly connected to the pressing plate 5, the The hollow positioning key 2 is set outside the cam, and the stopper 3, the pressure plate 5 and the upper rotary body 7 together form a slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com