Outer front flap positioner

A locator and front flap technology, which is applied in the field of mechanical design and process equipment manufacturing, can solve problems such as single positioning function and complex tooling structure, and achieve the effect of overcoming multiple types, reasonable and compact structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

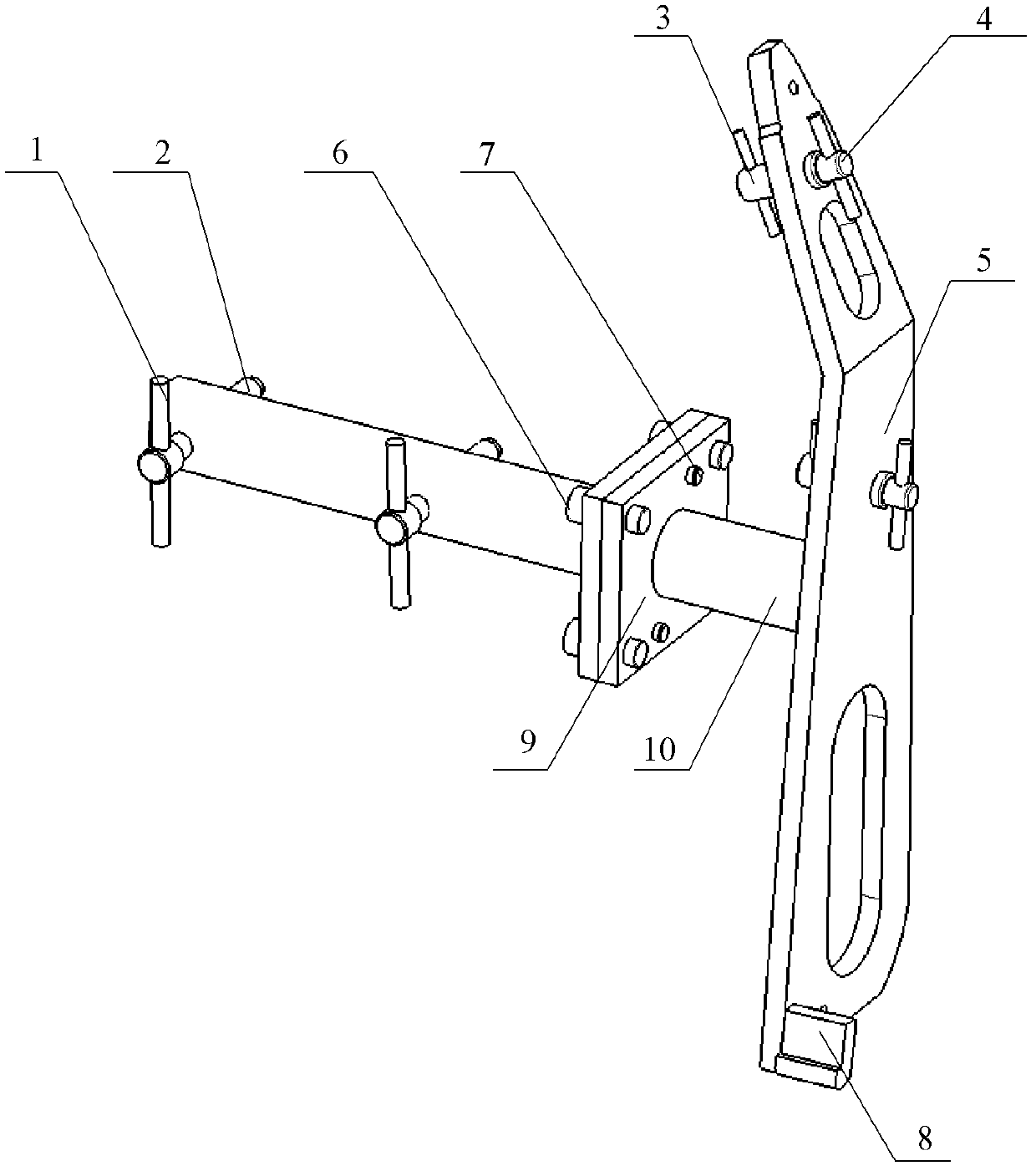

[0018] This embodiment is an outer front flap positioner, which is used for locating and clamping the big end parts of the outer front flap of an assembled aircraft. When in use, after adjusting the column of the mounting locator in place, insert the support arm sleeve into the mounting support, and after the installation is in place, match the positioning pin holes on the support through the two positioning pin holes on the support arm sleeve. Use two cylindrical pins with movable handles to insert into the positioning pin holes to complete the connection of the arm sleeve and the mounting bracket.

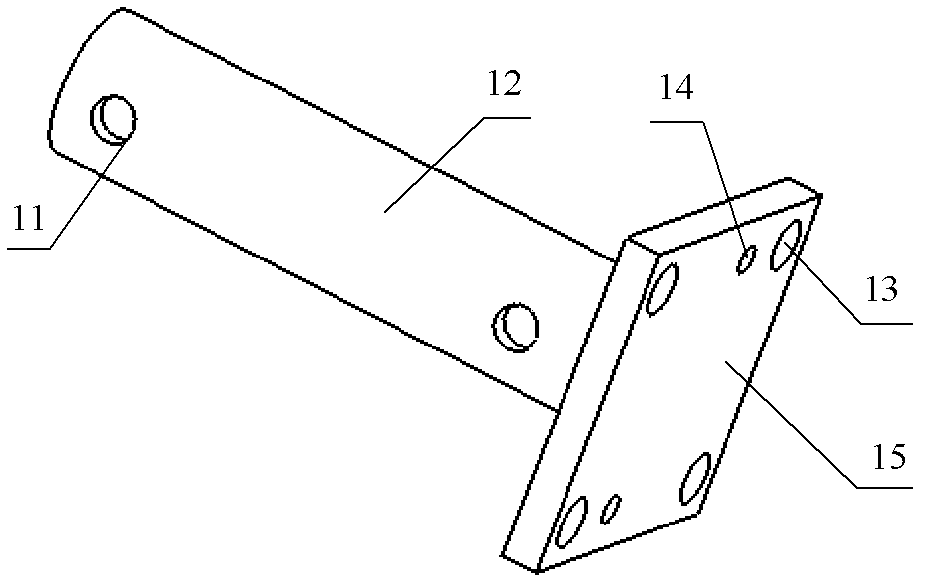

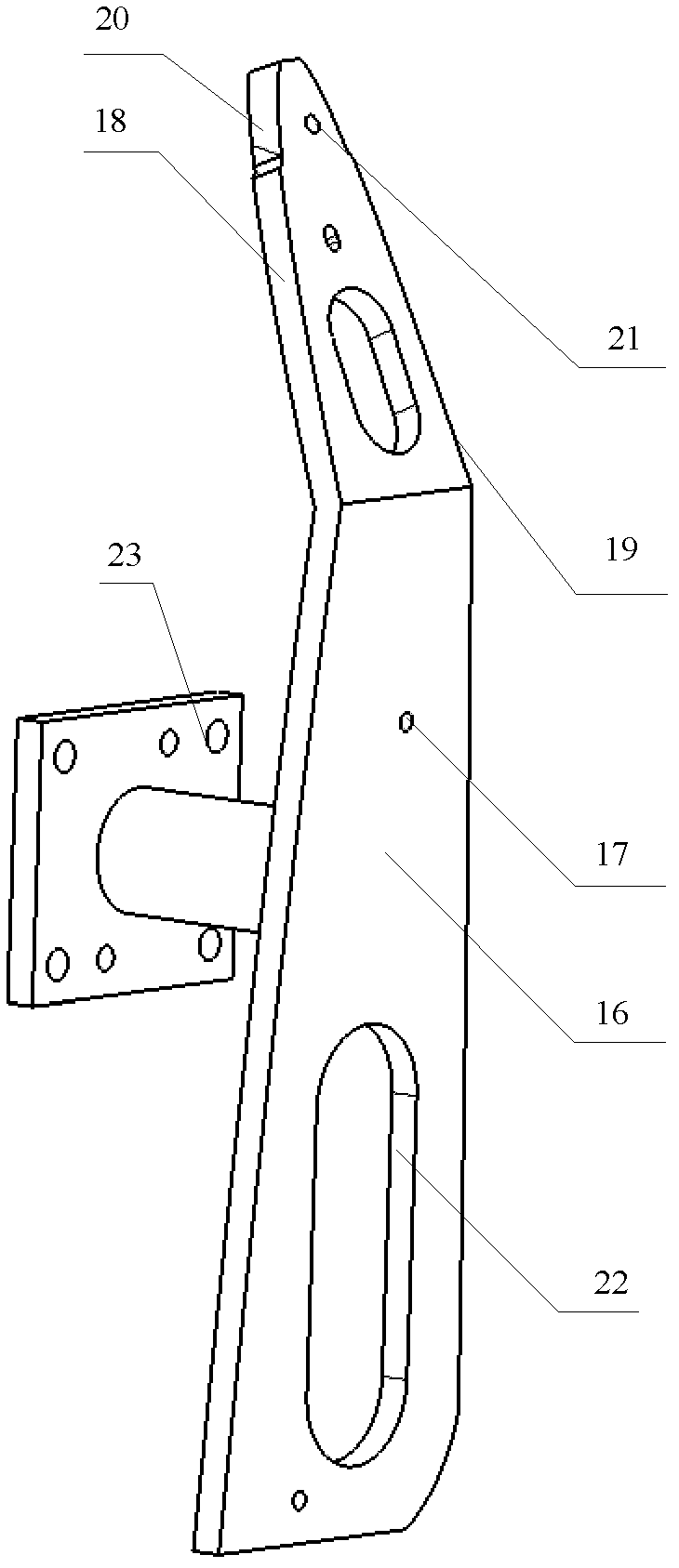

[0019] Such as figure 1 , figure 2 , image 3 As shown, the outer front flap positioner of the present invention includes a rib positioning plate 5, a connecting sleeve 10, a positioning plate connecting flange 9, a sleeve connecting flange 15, and a support arm sleeve 12, and the rib positioning plate also includes a front Edge strip inner shape positioning surface 20, wing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com