Lock catch sticking cardboard to carton and carton making method

A box forming and locking technology, which is applied in papermaking, locking equipment, paper/cardboard containers, etc., can solve problems such as waste, scratches on the contents, and gussets falling off, so as to reduce production costs, avoid waste, and lock firmly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In a preferred embodiment of carton single-piece cartoning, the following methods can be used: add multiple layers of glue-eating holes to the sticky mouth, destroy the original physical indicators of the sticky cardboard and crush it, and use the sticky cardboard as an anti-package Scratch and sticky lock into box lock box buckle penetration hole drilling treatment, mechanical box into box, install anti-scratch sticky lock box box lock box snap box, electric drill assembly screw in anti-scratch and sticky lock by package The box lock has a blade buckle, and the carton is glued and locked into a box. specifically:

[0071] Add multi-layer glue-eating holes to the sticky mouth: according to the size of the carton, the quality of the packaged goods, and the requirements for breaking resistance, do multi-layer glue-eat hole punching on the sticky mouth (completed simultaneously with printing);

[0072] Destroying the original physical indicators of the sticky cardboard an...

Embodiment 2

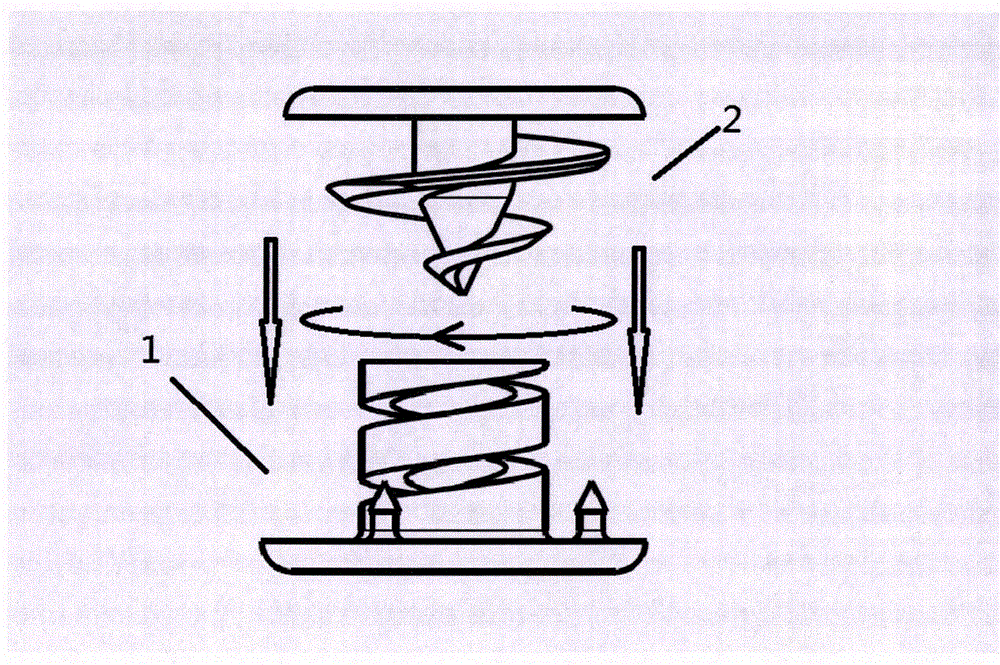

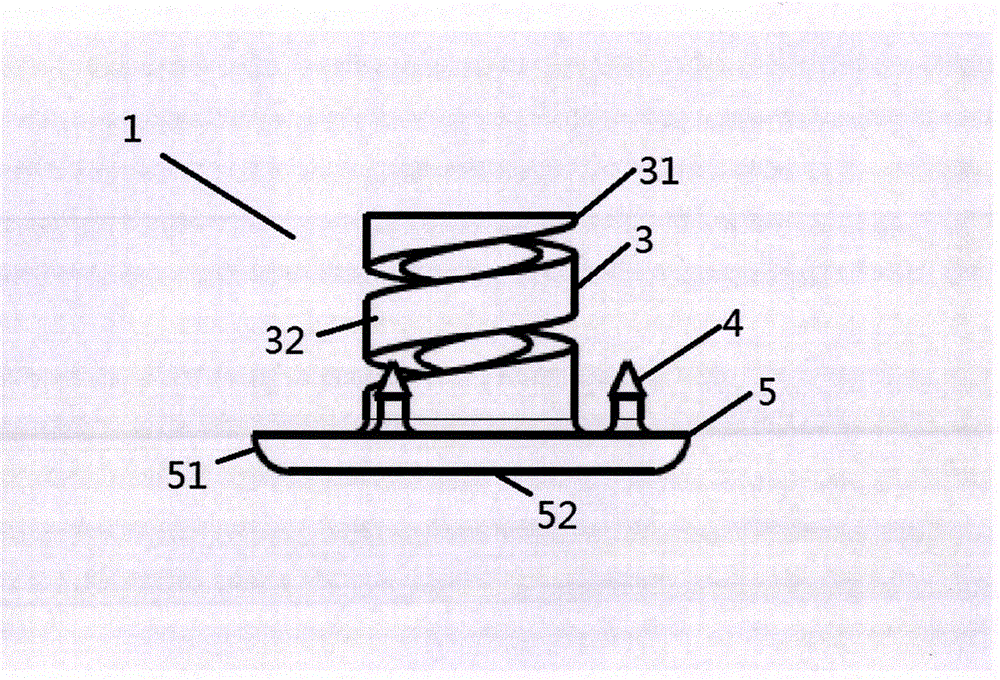

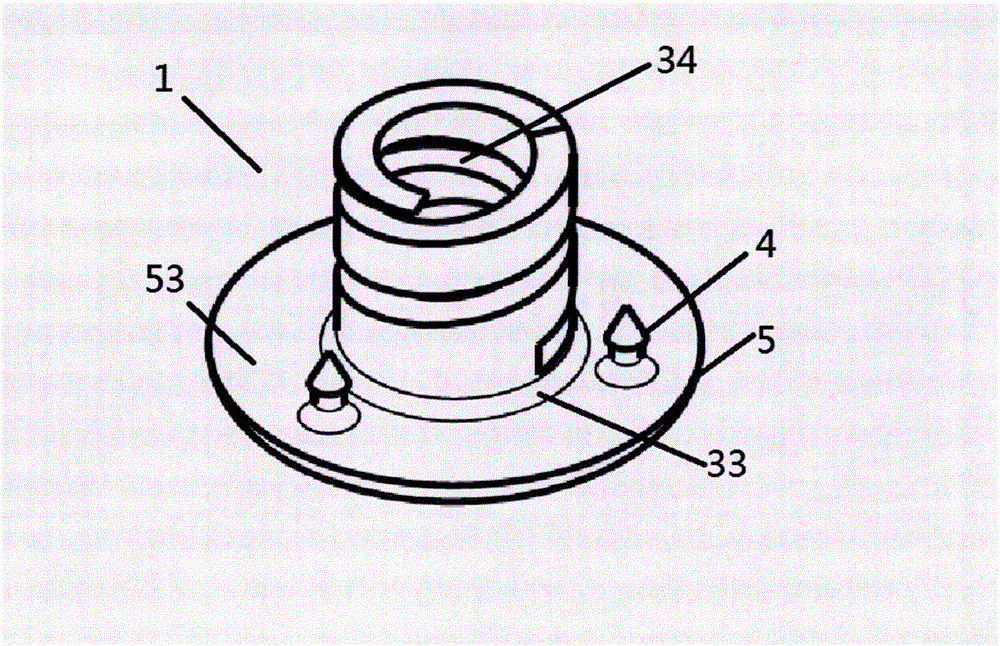

[0078] refer to figure 1 , a kind of sticky locking box lock, including a female buckle 1 and a child buckle 2, wherein the female buckle 1 includes a screw-in structure 3, at least one locking nail 4 and a bottom plate 5, and the screw-in structure 3 is arranged on the bottom plate 5 and used For the helical blade 6 accommodating the sub-buckle 2, the locking nail 4 is arranged on the base plate 5; 3 to realize the fastening of the female buckle 1 and the child buckle 2.

[0079] see Figure 2-Figure 8 as well as Figure 10-Figure 16 , the bottom plate 5 of the female button 1 is provided with the surface of the screw-in structure 3 as a first circular plane 53, the screw-in structure 3 is set at the center of the first circular plane 53, and the locking nail 4 is set at the first circular plane 53. On the plane 53 , the surface of the bottom plate 7 of the sub-clasp 2 on which the helical blade 6 is disposed is a second circular plane 73 , and the helical blade 6 is dispo...

Embodiment 3

[0098] In another preferred embodiment, the following scheme can be adopted: the third boxing method---sticking and locking into boxes (locking into boxes-directly linking two layers of cardboard with locks, no need to use glue for bonding). That is, the carton is made into a single piece of carton, and the adhesive mouth is processed by adding multiple layers of glue holes, destroying the original physical indicators of the adhesive cardboard, and the adhesive cardboard is used to prevent scratches from being scratched by the packaging. Hole punching treatment, mechanical gluing into boxes, installation of anti-scratch and sticky-locked box lock female buckles, electric drill assembly, screwing in anti-scratch and sticky-locked box locks with blade buckles, and completion of cartons Glued into boxes.

[0099] Add multi-layer glue-eating holes to the sticky mouth: according to the size of the carton, the quality of the packaged goods, and the requirements for breaking resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com