Wear-resisting and noise-reducing automobile semi-axle

A car half shaft and noise reduction technology, applied in the direction of axles, wheels, vehicle parts, etc., can solve the problems of poor wear resistance and loud noise, and achieve outstanding wear resistance and noise reduction capabilities, performance improvement, wear resistance and Effect of Noise Cancellation Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

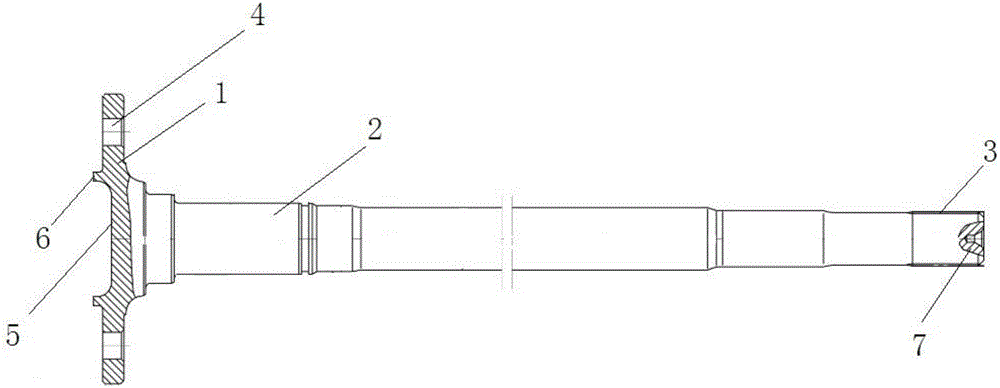

[0035] Its structure of the automobile semi-axle of the present embodiment is referring to figure 1 , including: a flange 1 used to connect the bridge body, a half-shaft 2 integrally formed with the flange 1, and a spline shaft 3 formed at the end of the half-shaft 2, formed on the flange 1 There are several bolt connection holes 4 for connecting with the bridge body, a central hole 7 is formed at the end of the spline shaft 3 for connecting with the hub, and spline teeth are processed on the surface of the spline shaft 3 .

[0036] It should be noted that a groove 5 is formed in the middle of the side of the flange 1 away from the spline shaft 3, and a pair of lugs 6 are symmetrically arranged between the groove 5 and the upper surface of the flange 1. Compared with the groove 5 The depth of the upper surface of the flange 1 is 1 mm, and the intersection of the side wall and the bottom wall of the groove 5 is rounded, and the height of the lug 6 compared to the upper surface ...

Embodiment 2

[0038] The structure of the automobile half shaft of this embodiment is the same as that of Embodiment 1, specifically including: a flange 1 for connecting the bridge body, a half shaft 2 integrally processed with the flange 1, and a half shaft formed at the end of the half shaft 2 The spline shaft 3 at the top of the flange 1 is formed with a number of bolt connection holes 4 to connect with the bridge body, the end of the spline shaft 3 is formed with a central hole 7 to connect with the hub, and the surface of the spline shaft 3 is processed with spline teeth.

[0039]It should be noted that a groove 5 is formed in the middle of the side of the flange 1 away from the spline shaft 3, and a pair of lugs 6 are symmetrically arranged between the groove 5 and the upper surface of the flange 1. Compared with the groove 5 The depth of the upper surface of the flange 1 is 2 mm, and the intersection of the side wall and the bottom wall of the groove 5 is rounded, and the height of t...

Embodiment 3

[0042] Its structure of the semi-axis of the automobile of the present embodiment is identical with embodiment 1, and it is important to emphasize that: the surface of the semi-axis of the automobile is also coated with a thick composite coating of 5 micrometers (μm), and the composite coating consists of the following parts by weight Each component is made: 50 parts of solvent (all parts by weight, the same below), 30 parts of binder, 10 parts of hollow silica microspheres, 5 parts of nano-titanium dioxide, 4 parts of aluminum tripolyphosphate, 3 parts of diatomaceous earth part and 2 parts of surfactant. Among them, the solvent is composed of 3 parts of polyvinyl alcohol and 47 parts of deionized water; the average particle size of the silica hollow microspheres is 1-3 μm, and the average particle size of nano-titanium dioxide is 50-80 nm; the adhesive is epoxy resin, The surfactant is selected from sodium fatty acid methyl ester sulfonate, fatty alcohol ether phosphate or f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com