Thrust mechanism for filling device of universal aircraft

The technology of a loading device and a driving mechanism is applied to aircraft parts, ground devices, and equipment for loading and unloading cargo, etc. It can solve the problems of large floor area, high management costs, high maintenance costs, and difficulty in universal loading devices. Improve work efficiency, simple and reliable structure, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

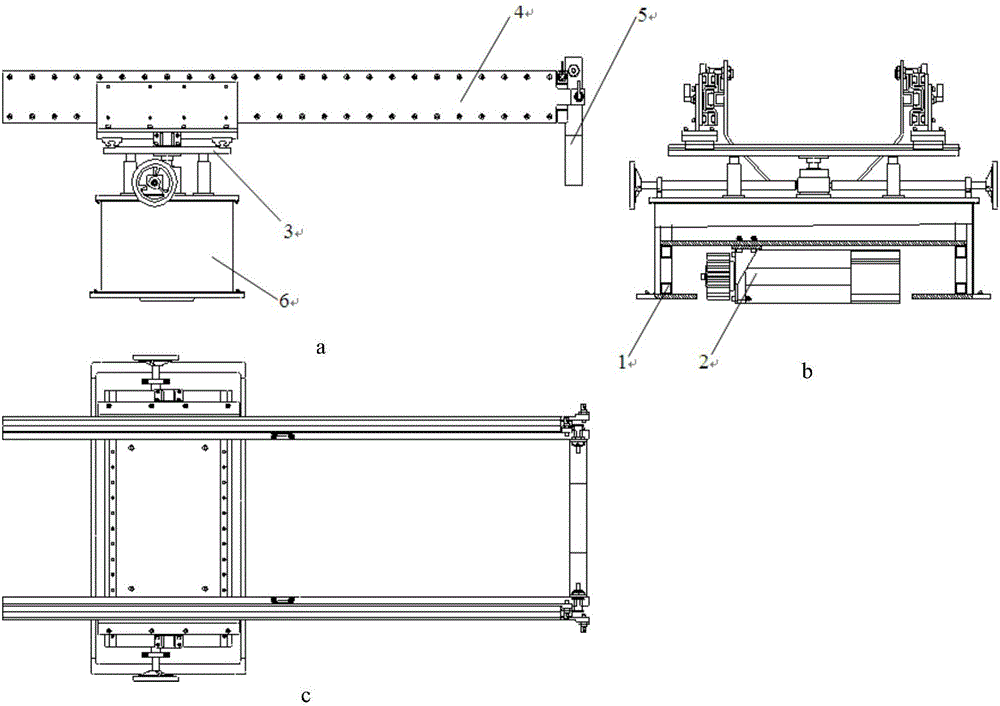

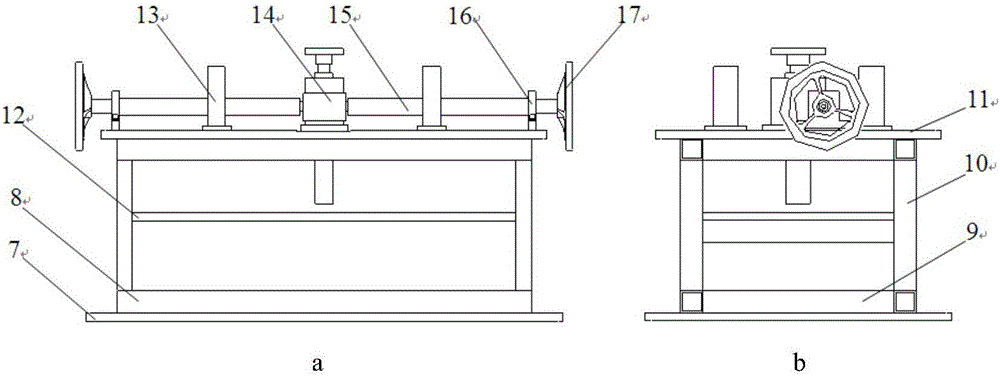

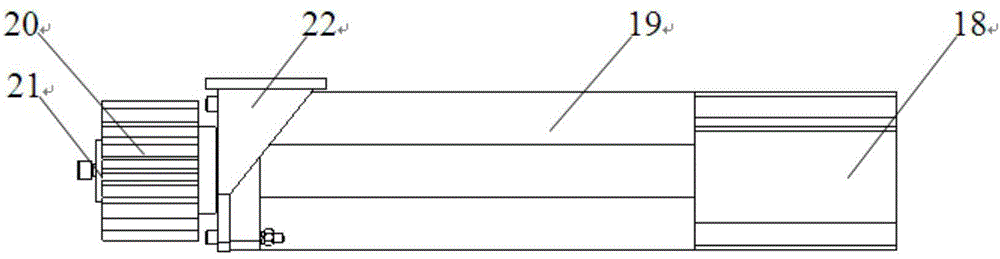

[0025] like figure 1 As shown, the pushing mechanism for a general-purpose aircraft loading device provided by the embodiment of the present invention includes a base 1 , a motor actuator 2 , a bodywork mounting seat 3 , a push rod mechanism 4 , a locking mechanism 5 and an outer cover 6 . The motor actuator 2 is fixed in the base 1 by bolts, the bodywork mounting seat 3 is screwed on the top of the worm gear screw lifter 14 in the base 1, and the push rod mechanism 4 has two groups, which are respectively fixed on the straight line of the bodywork mounting seat 3 by screws. On the guide rail pair 25, the distance between two groups of push rod mechanisms 4 is adjustable, the locking mechanism 5 is screwed to the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com