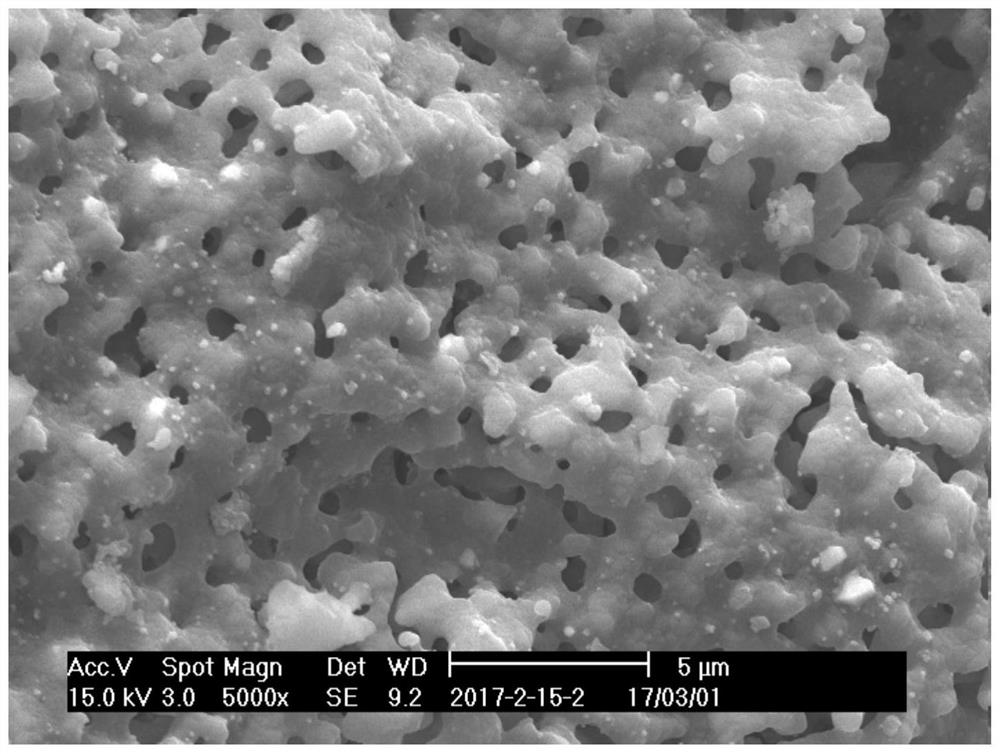

Strip-shaped silicon dioxide carrier with grid structure, preparation method thereof, catalyst and application

A technology of silica and grid structure, applied in the field of porous materials, can solve the problems of complex process, low strength, and limited application of porous silica strips, and achieve unbreakable, good compression resistance, and equipment requirements simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A first aspect of the present invention provides a method for preparing a strip-shaped silica carrier with a grid structure, wherein the method includes:

[0019] (1) mixing silicon dioxide with starch and / or Tianqing powder to obtain material A;

[0020] (2) Nitrate, paratungstate, silica sol and water are mixed to obtain material B;

[0021] (3) mixing and kneading the material A and the material B into a plastomer, and extruding the plastomer into a strand and drying and calcining;

[0022] Wherein, the nitrate is sodium nitrate and / or potassium nitrate;

[0023] Wherein, the paratungstate is one or more of sodium paratungstate, potassium paratungstate and ammonium paratungstate.

[0024] In the present invention, the average particle size is measured by a laser particle size distribution analyzer, and the specific surface area and pore volume are measured by a nitrogen adsorption method.

[0025] According to the present invention, the average particle size of th...

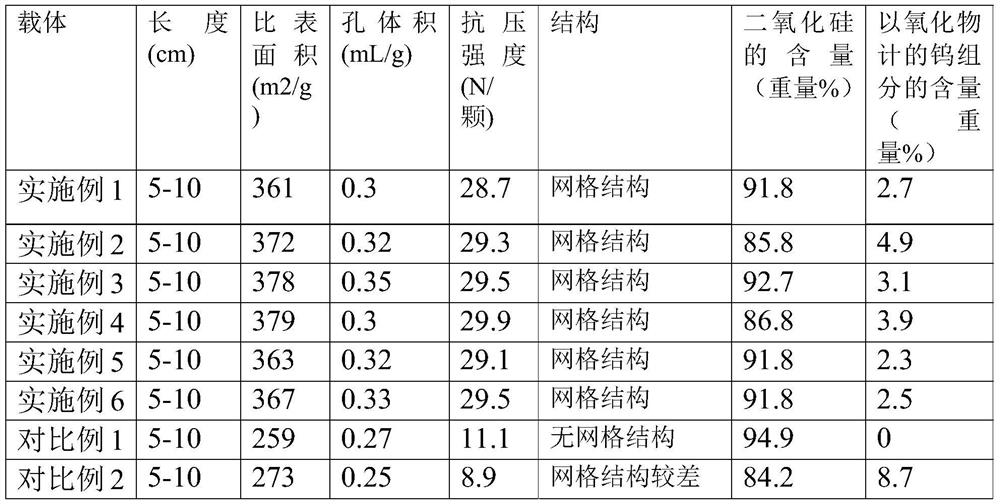

Embodiment 1

[0048] This example is to illustrate the strip-shaped silica carrier with grid structure prepared by the method of the present invention.

[0049] (1) fully mix 100g silicon dioxide solid powder (80 mesh) and 10g starch to obtain material A;

[0050] (2) fully mixing 12g of silica sol (calculated by silica), 6g of sodium nitrate, 4g of ammonium paratungstate and 45g of water with a silica content of 30% to obtain material B;

[0051] (3) Under the condition of continuous stirring at a stirring rate of 50 r / min, the materials A and B are fully mixed and kneaded into a wet plastic body; in a stainless steel kneading extruder, the extrusion rate is 150 r / min through an orifice plate of Φ2 mm. The elongated solid cylinder extruded under the conditions of ;

[0052] (4) drying at room temperature for 12 hours, drying at 80 ° C for 8 hours, then, calcining at 850 ° C for 8 hours, the temperature rise rate from room temperature to the set roasting temperature is 4 ° C / min, and the r...

Embodiment 2

[0056] This example is to illustrate the strip-shaped silica carrier with grid structure prepared by the method of the present invention.

[0057] (1) fully mix 100g silicon dioxide solid powder (100 mesh) and 25g starch to obtain material A;

[0058] (2) fully mixing 8g of silica sol (calculated by silica), 10g of sodium nitrate, 8g of sodium paratungstate and 64g of water with a silicon dioxide content of 25% to obtain material B;

[0059] (3) Under the condition of continuous stirring at a stirring rate of 140 r / min, the materials A and B are fully mixed and kneaded into a wet plastic body; in a stainless steel kneading extruder, the extrusion rate is 400 r / min through an orifice plate of Φ2 mm. The elongated solid cylinder extruded under the conditions of ;

[0060] (4) drying at room temperature for 10 hours, drying at 140 ° C for 4 hours, then, calcining at 900 ° C for 6 hours, the heating rate from room temperature to the set roasting temperature is 5 ° C / min, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com