Polishing waste slag recycling method and facility used by method

A technology for polishing waste residue and waste residue, which is applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as no introduction, and improve mixing efficiency and efficiency , to reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

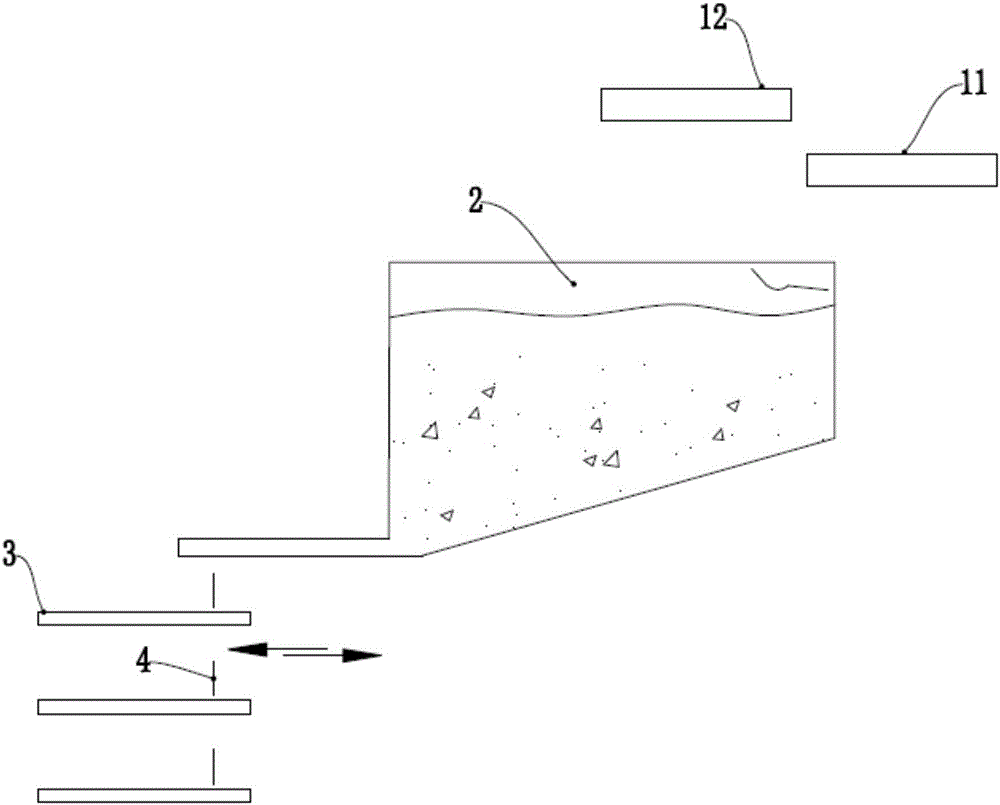

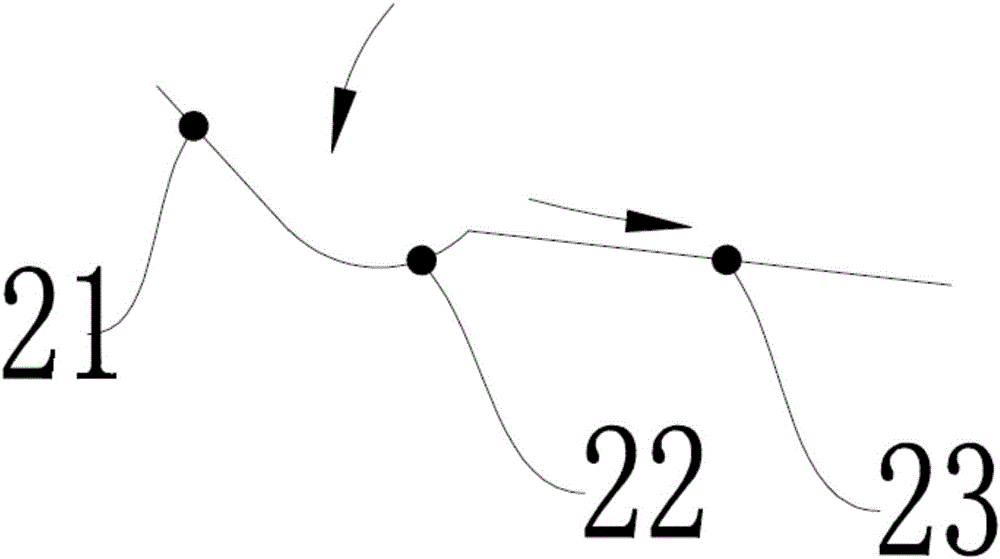

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] The polishing waste residue recycling method of this embodiment, the present embodiment divides the polishing waste residue into foaming waste residue and non-foaming waste residue, said foaming waste residue refers to polishing waste residue containing resin, silicon carbide, magnesium chloride and other components; said non-foaming waste residue Foaming waste refers to polishing waste that does not contain resin, silicon carbide, magnesium chloride, etc., and non-foaming waste can be recycled by existing conventional treatment methods, which will not be explained in detail here;

[0027] The recycling of foaming waste slag described in the present embodiment comprises the following steps:

[0028] A. Settling, after the flocculant is added to the polishing waste water of the foaming waste r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com