Bubble processing method and device

A treatment method and foam technology, which is applied to washing devices, textiles and papermaking, and other washing machines, etc., can solve problems such as poor foam effect, and achieve the effect of solving poor results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to an embodiment of the present invention, an embodiment of a foam treatment method is provided. It should be noted that the steps shown in the flowcharts of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and, although in The flowcharts show a logical order, but in some cases the steps shown or described may be performed in an order different from that shown or described herein.

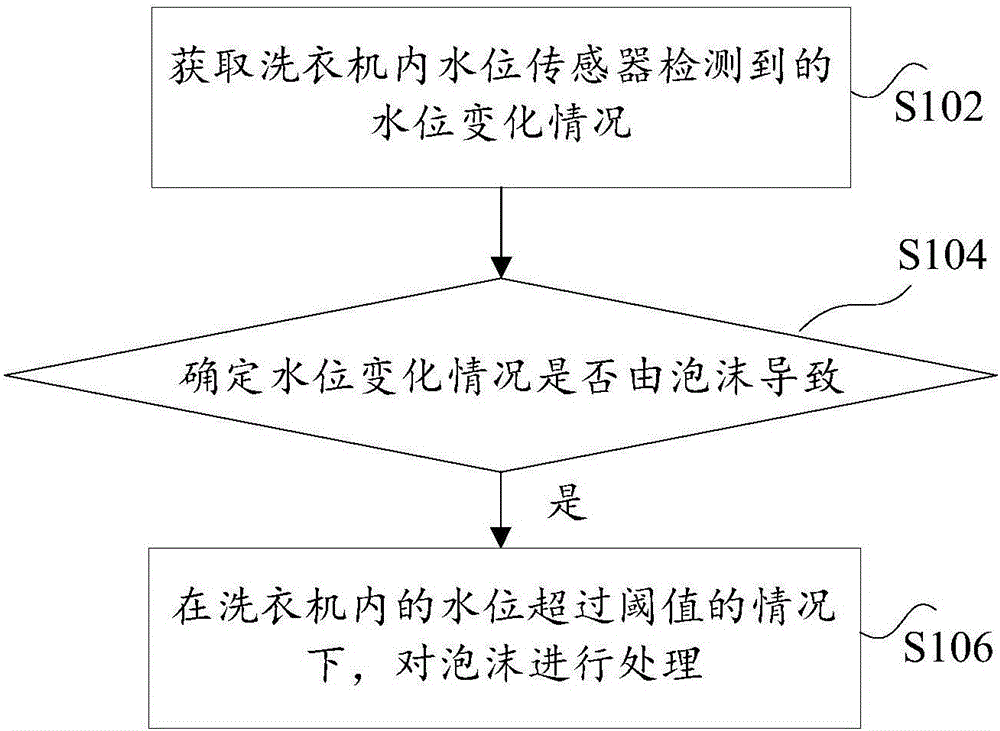

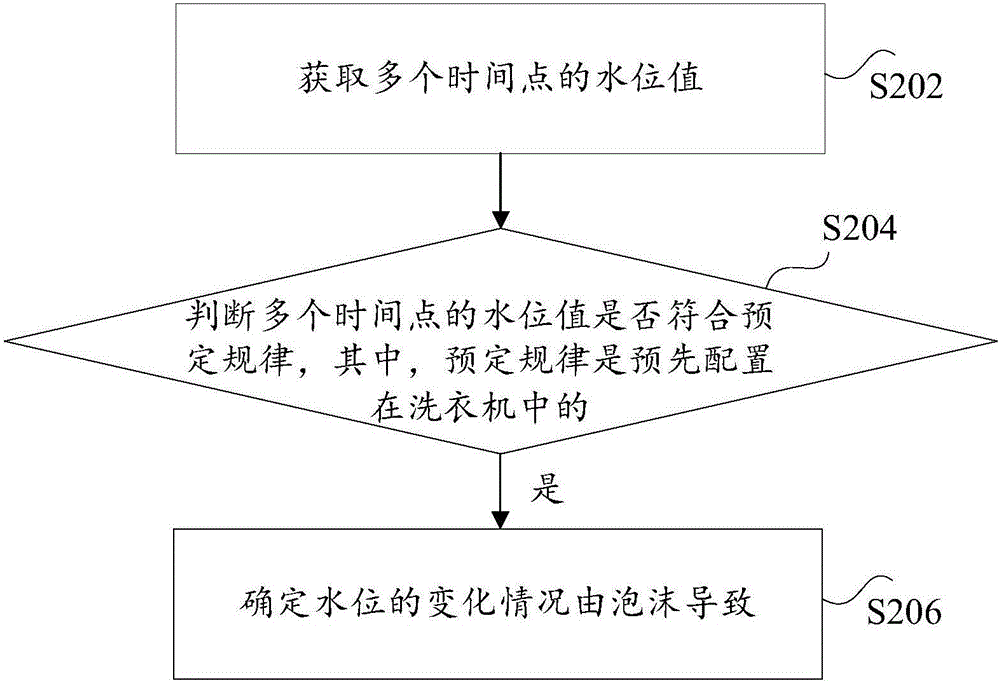

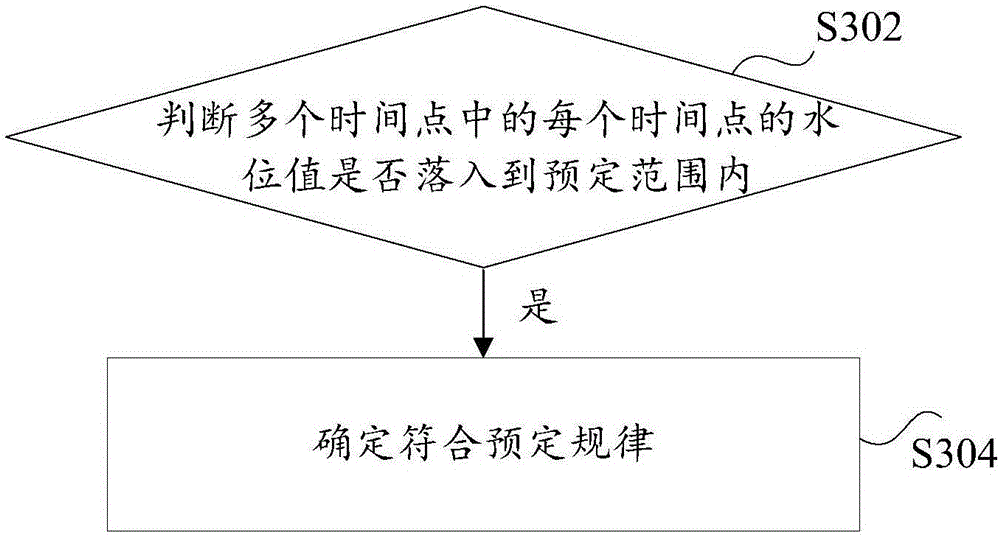

[0020] figure 1 It is a flow chart of a foam treatment method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0021] Step S102, acquiring the change of the water level detected by the water level sensor in the washing machine;

[0022] Step S104, determining whether the water level change is caused by foam;

[0023] In step S106, if the change in the water level is caused by foam, and the water level in the washing machine exceeds a threshol...

Embodiment 2

[0069] According to an embodiment of the present invention, an embodiment of a foam treatment device is also provided. The foam treatment method in Embodiment 1 of the present invention can be implemented in the device of Embodiment 2 of the present invention.

[0070] Figure 5 is a schematic diagram of a foam treatment device according to an embodiment of the present invention, such as Figure 5 As shown, the device includes: an acquisition module 501 , a determination module 503 and a processing module 505 .

[0071] Among them, the acquisition module 501 is used to obtain the water level change detected by the water level sensor in the washing machine; the determination module 503 is used to determine whether the water level change is caused by foam; the processing module 505 is used to determine whether the water level change is caused by foam. And, when the water level in the washing machine exceeds the threshold value, the foam is processed.

[0072] It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com