Phase-change cold storage device and cold supply system with same

A cold system and phase change technology, which is applied in the field of cooling systems and phase change animal cooling devices, can solve the problems of reducing cold storage efficiency and cold storage effect, large temperature stratification of energy storage materials, and loss of life of energy storage materials, etc., to achieve improved Cool storage efficiency and cool storage effect, improve energy utilization efficiency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

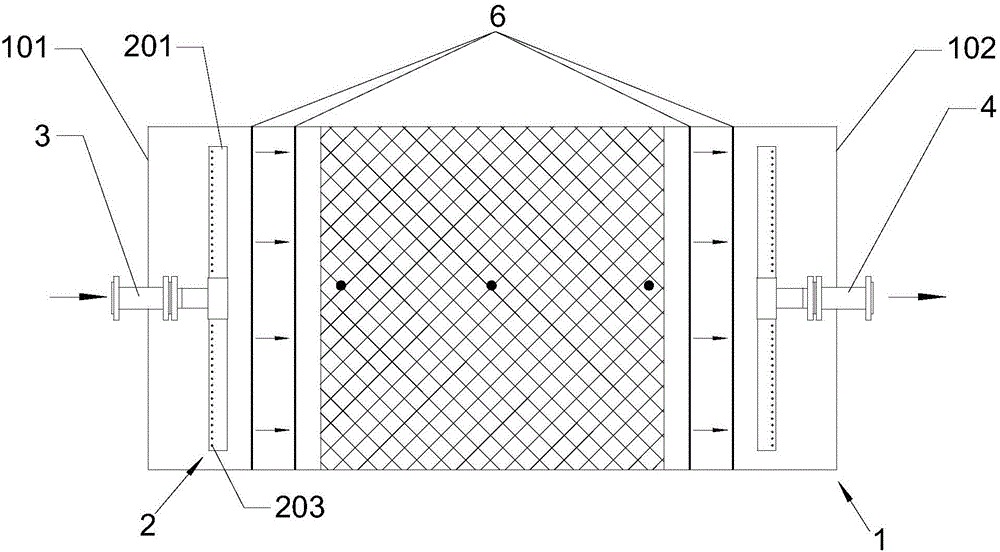

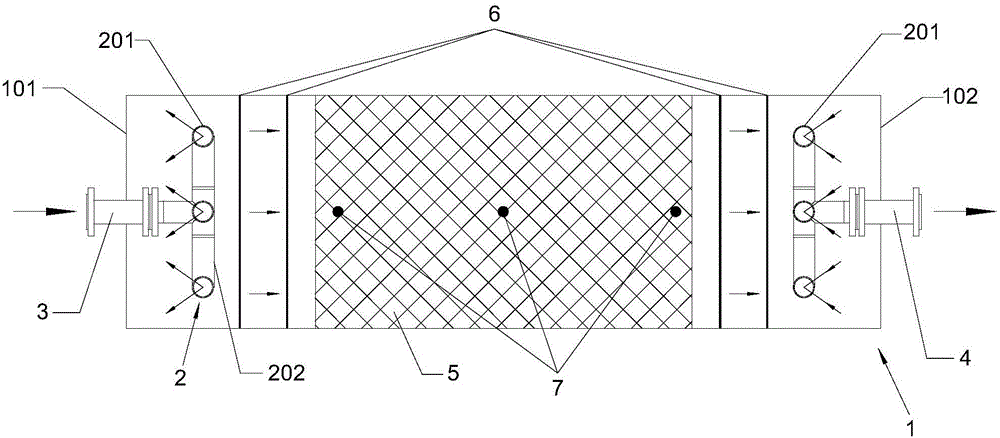

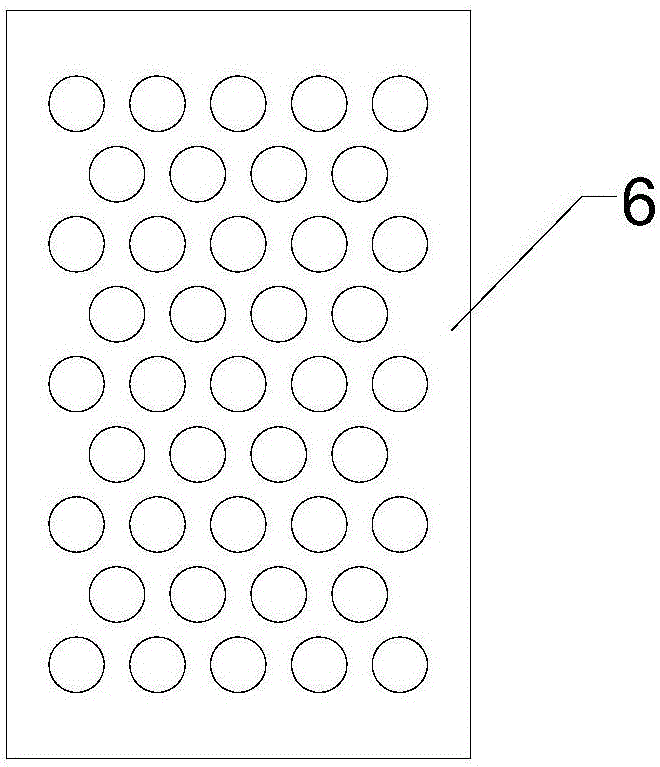

[0043] figure 1 is the front view of this embodiment, figure 2 is a top view of this embodiment. In this embodiment, a phase change cooling device includes a housing 1, an energy storage material 5, a water inlet pipe 3 and a water outlet pipe 4, the energy storage material 5 is arranged inside the housing 1, and the water inlet pipe 3 is arranged in the housing 1 on the water inlet end plate 101, and the water outlet pipe 4 is arranged on the water outlet end plate 102 of the housing 1; wherein: one end of the water inlet pipe 3 and the water outlet pipe 4 in the housing 1 communicates with a shunt assembly 2 respectively The splitter assembly 2 is arranged at the middle position of the height and width of the inner space of the housing 1, the standpipe 201 is evenly distributed along the width direction of the housing 1, and the horizontal tube 202 is evenly distributed along the height direction of the housing 1; the two splitter assemblies 2 and Splitter plates 6 are ar...

Embodiment 2

[0051] The cooling system is mainly divided into cold storage process and cooling process.

[0052] Cold storage process such as Figure 4 As shown, the cold water from the chiller 8 passes through the one-way valve, the first hose, the water pump, the second hose, the valve, etc., and then enters the phase-change cold storage device described in Embodiment 1, and transfers heat energy to the energy storage material 5 After that, the temperature of the cold water rises and returns to the unit, so the cycle is repeated. During the circulation process, judge whether the energy storage material 5 has realized excessive cold storage according to the temperature collected by the temperature sensor 7, and also judge whether there is temperature stratification in the energy storage material 5, and adjust the speed of the water pump or the opening of the valve according to the temperature stratification , and then adjust the distribution of water flowing through the phase change anim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com