Phase-change cold storage module and manufacturing tool and manufacturing method thereof

A technology of phase change cold storage and fixed tooling, which is applied in heat storage equipment, lighting and heating equipment, indirect heat exchangers, etc., to reduce manufacturing costs, increase cold storage capacity, and solve poor weldability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

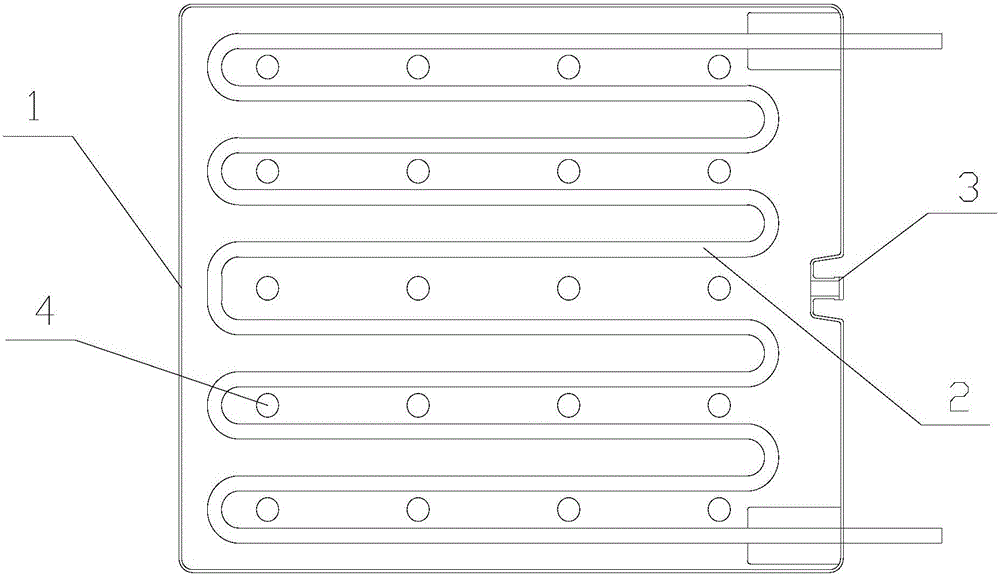

[0028] figure 1 A specific embodiment of the present invention is shown: a phase change cold storage module, including a module housing 1, the module housing 1 is a cavity structure, the evaporator 2 is built in the formwork housing 1, and the evaporator inlet is arranged on the side wall of the module housing 1 , the outlet of the evaporator is arranged on the side wall of the module shell 1, and the side wall of the module shell 1 is provided with a cold storage material filling port 3, and the cold storage material filling port communicates with the inner cavity of the module shell 1, and the module shell is made of high-density polyethylene Made of engineering plastics.

[0029] The evaporator 2 is a serpentine tube evaporator inside the module shell 1; the template shell 1 is provided with a module pull stud 4, and the template pull stud 4 is used to fix the evaporator 2 and prevent the module shell from deforming.

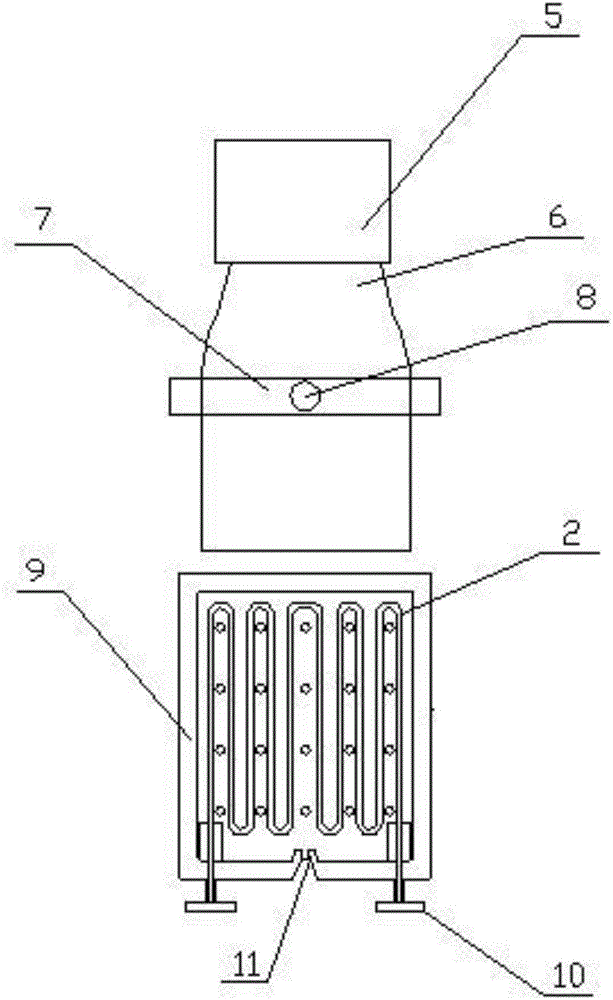

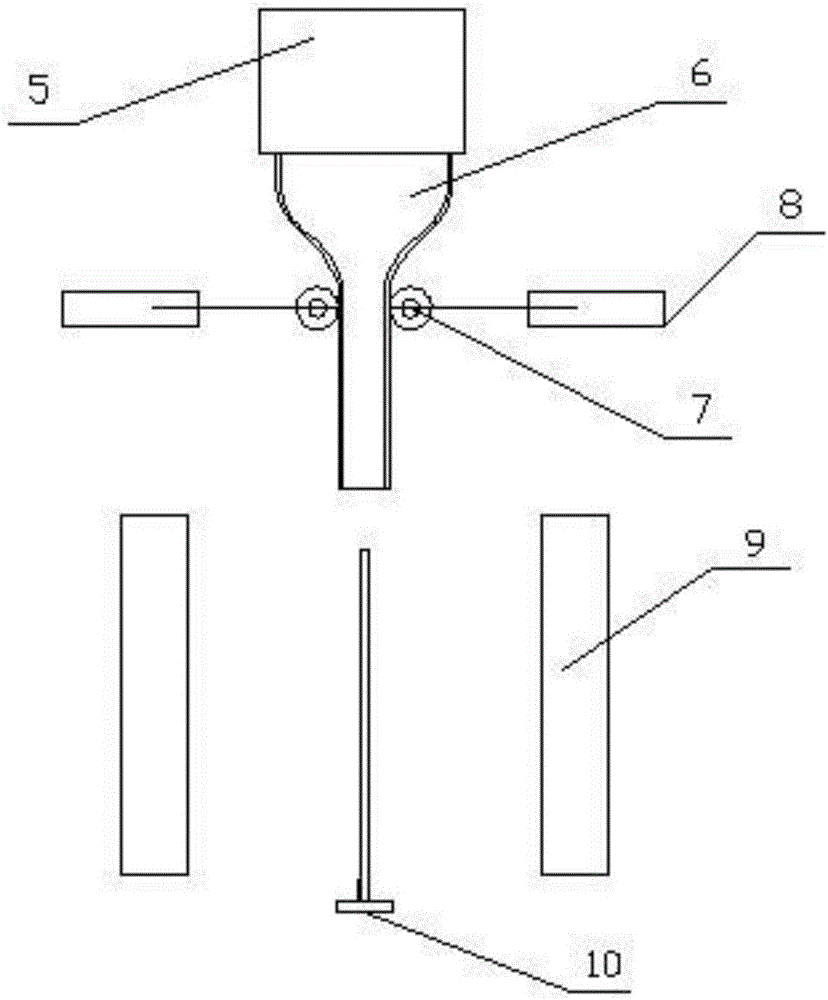

[0030] combine figure 2 and image 3 , a manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com