A hydraulic viscous transmission test device with controllable friction plate quantity and oil film thickness

A technology of oil film thickness and transmission test, which is applied in the direction of measuring device, machine gear/transmission mechanism test, mechanical component test, etc. It can solve the problems of inefficient use of resources, achieve convenient measurement, reduce the maximum thickness, The effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

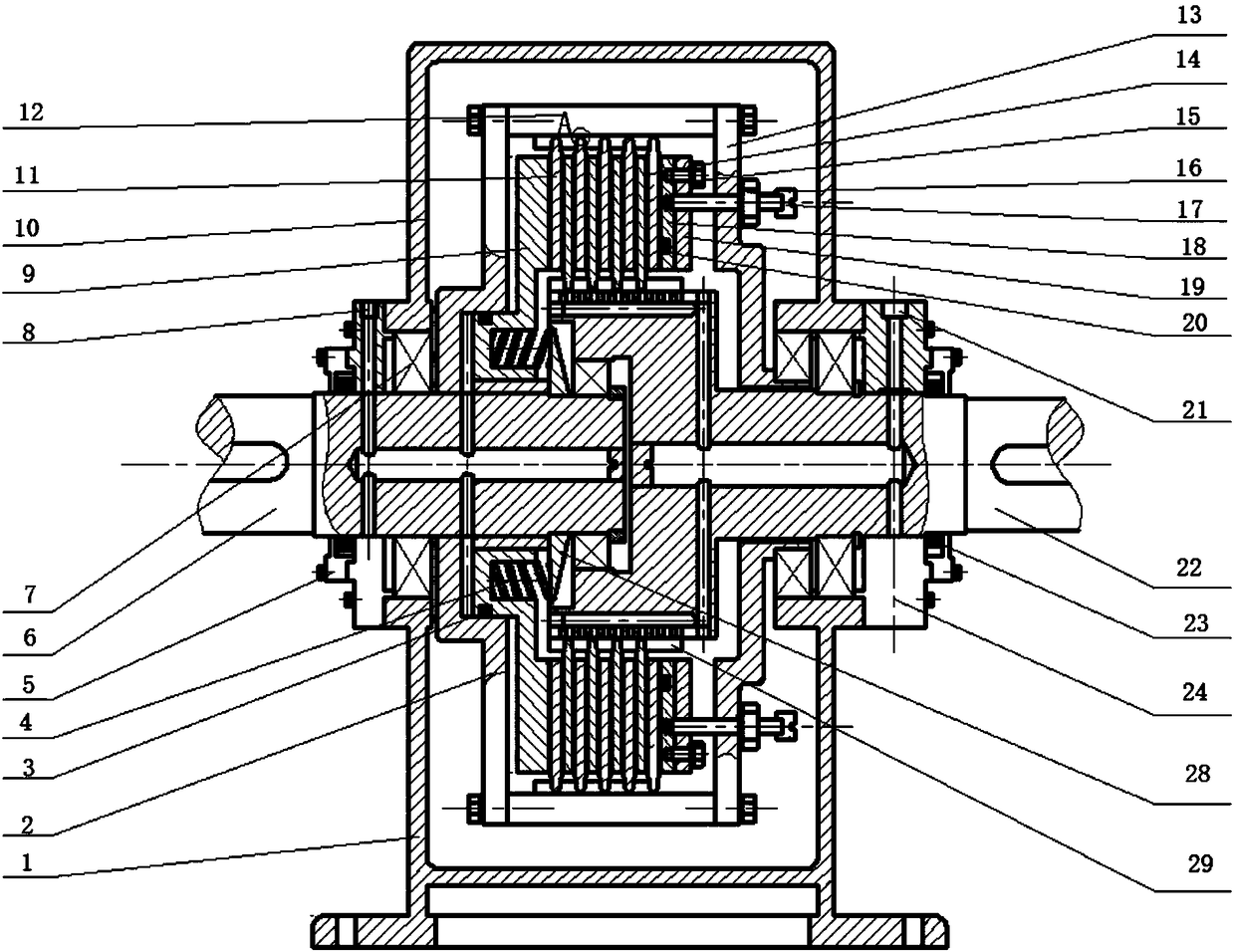

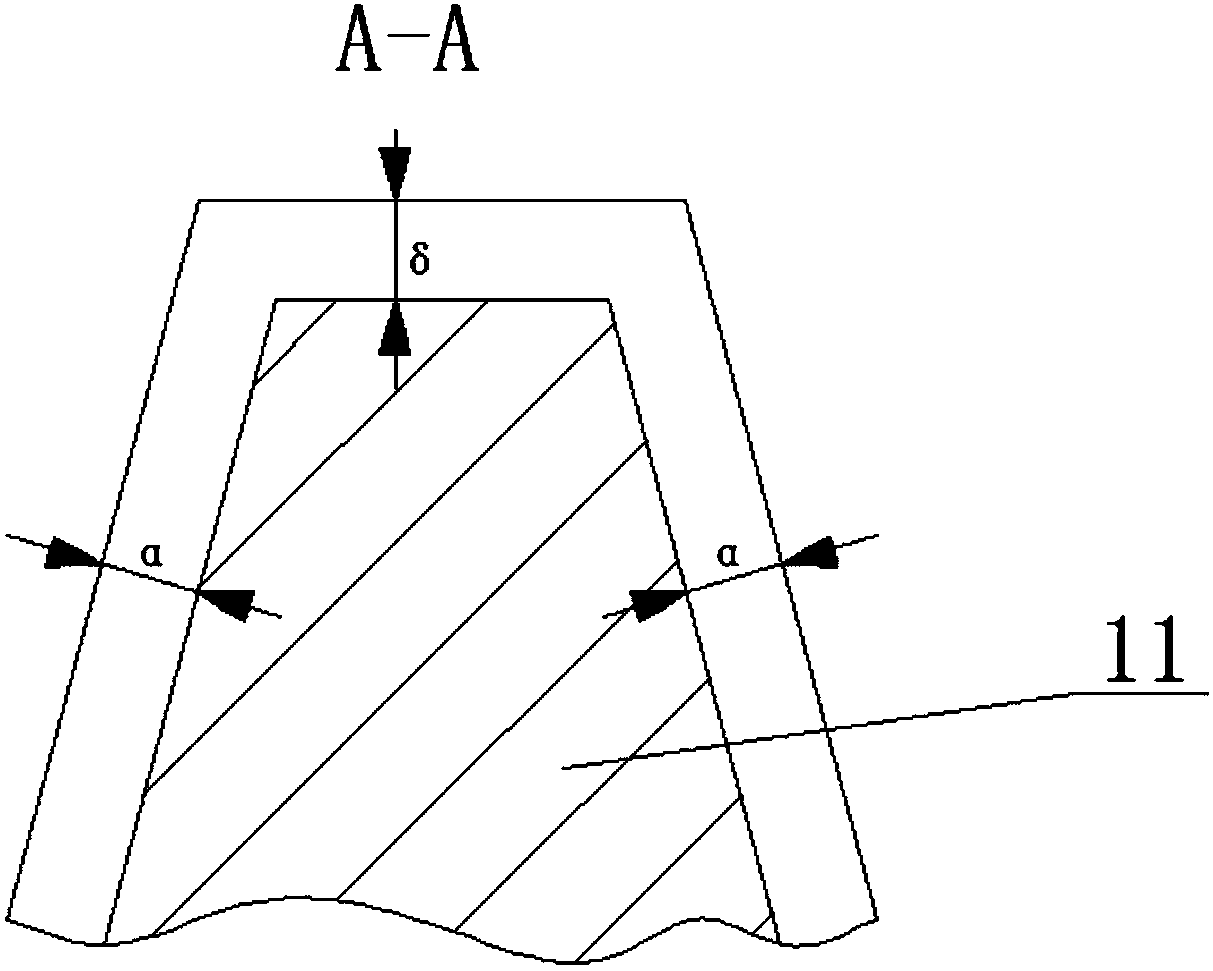

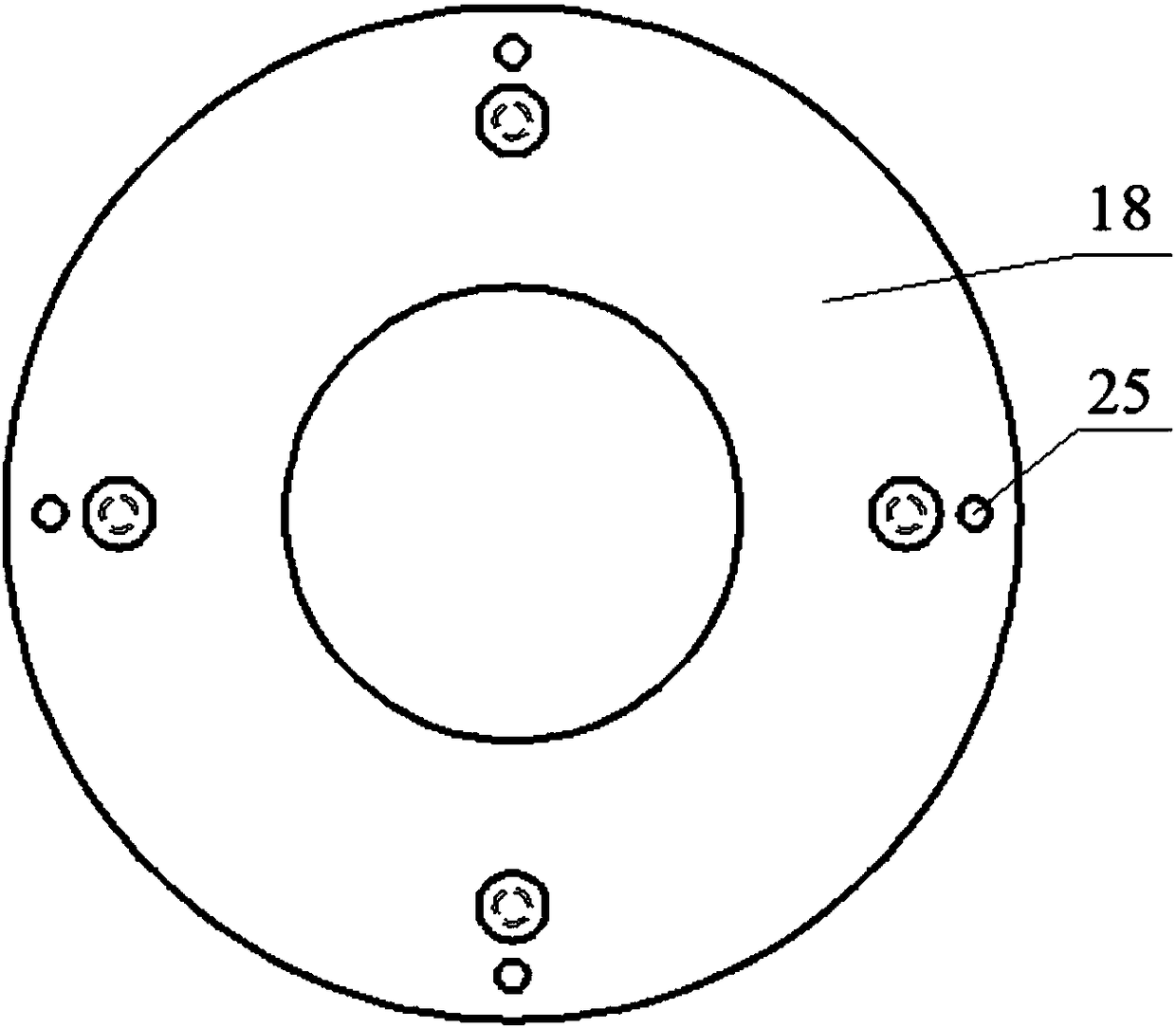

[0033] Combine below figure 1 , 2 , 3, 4 and 5, a fluid-viscous transmission test device with controllable friction plate quantity and oil film thickness proposed by the present invention will be further described in detail.

[0034] combined with figure 1 , a hydraulic viscous transmission test device with controllable friction plate quantity and oil film thickness, comprising an upper box body 10, a lower box body 1, a passive disc 2, a driving disc 13, an active friction plate 14 and a passive friction plate 11;

[0035] The upper box 10 and the lower box 1 are connected together by bolts; one end of the driving shaft 22 and the driven shaft 6 are respectively installed in the holes provided between the upper box 10 and the lower box 1; 22 coincides with the axis of the driven shaft 6; the drive shaft 22 has a T-shaped structure, and the outer ring of the T-shaped end of the drive shaft 22 is provided with gear teeth 29; One end is installed in the groove that the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com