Method for preparing plant oil-based isocyanate

An oil-based isocyanate and vegetable oil-based technology, which is applied in the field of preparation of vegetable oil-based isocyanates, can solve the problems of decreased application value, low reactivity, high price and the like, and achieves a controllable number of NCOs, high reaction yield, and improved reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

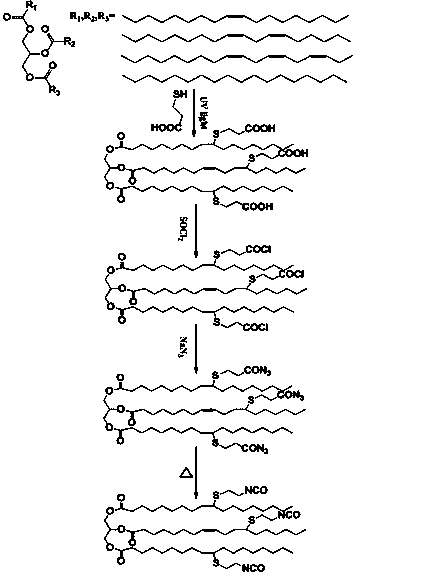

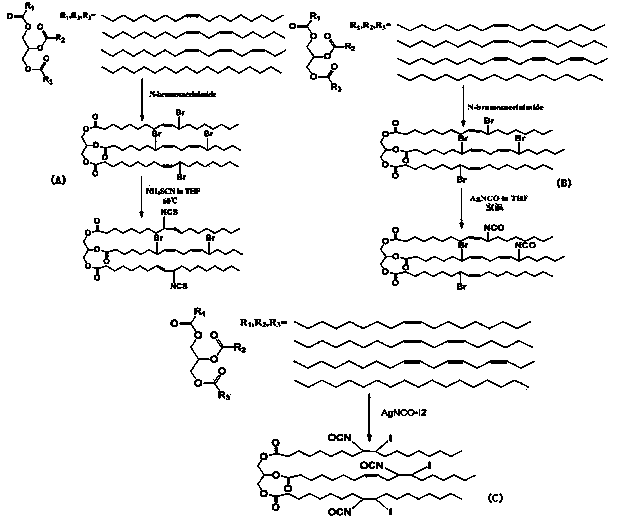

[0018] (1) Add 15.00g of rapeseed oil, 11.20g of 3-mercaptopropionic acid, 0.393g of 2, 2'-diethoxyacetophenone and 30ml of dichloromethane into the reaction flask, and use 1.8mw / cm 2 UV light was irradiated for 8 hours, excess 3-mercaptopropionic acid was removed by washing with deionized water, the organic layer was dried by anhydrous magnesium sulfate, and dichloromethane was removed by rotary evaporation to obtain 16.43 g of rapeseed oil-based carboxylic acid.

[0019] (2) Add 8.00g of rapeseed oil-based carboxylic acid, 6 drops of N,N-dimethylformamide, 20ml of dichloromethane, and 20.00g of thionyl chloride into the reaction flask, and stir at 45°C for 5 hours. Rotary evaporation removed dichloromethane and thionyl chloride to obtain rapeseed oilyl chloride.

[0020] (3) Add 1.79g of sodium azide and 19.45g of deionized water into the reaction flask, place in an ice bath, add dropwise the tetrahydrofuran solution dissolved in rapeseed oilyl chloride under stirring withi...

Embodiment 2

[0026] (1) Add 15.00g of corn oil, 13.32g of 3-mercaptopropionic acid, 0.798g of 2, 2'-dimethylbenzil ketal and 30ml of dichloromethane into the reaction flask, and use 1.8mw / cm 2 UV light was irradiated for 8 hours, excess 3-mercaptopropionic acid was removed by washing with deionized water, the organic layer was dried by anhydrous magnesium sulfate, and dichloromethane was removed by rotary evaporation to obtain 16.21 g of corn oilyl carboxylic acid.

[0027] (2) Add 8.00g of corn oil-based carboxylic acid, 6 drops of N,N-dimethylformamide, 20ml of dichloromethane, and 17.80g of thionyl chloride into the reaction flask, and stir at a temperature of 50°C After 5 hours, dichloromethane and thionyl chloride were removed by rotary evaporation to obtain corn oleyl chloride.

[0028] (3) Add 1.61g of sodium azide and 17.58g of deionized water into the reaction flask, place in an ice bath, add the tetrahydrofuran solution dissolved in corn oleyl chloride dropwise under stirring wi...

Embodiment 3

[0033] (1) Add 15.00g of soybean oil, 13.32g of 3-mercaptopropionic acid, 0.798g of 2-hydroxybenzophenone and 30ml of dichloromethane into the reaction flask, and use 1.8mw / cm 2 UV light was irradiated for 8 hours, excess 3-mercaptopropionic acid was removed by washing with deionized water, the organic layer was dried by anhydrous magnesium sulfate, and dichloromethane was removed by rotary evaporation to obtain 15.92 g of soybean oleyl carboxylic acid.

[0034] (2) Add 8.00g of soybean oil-based carboxylic acid, 6 drops of N,N-dimethylformamide, 20ml of dichloromethane, and 17.80g of thionyl chloride into the reaction flask, and stir at a temperature of 50°C After 5 hours, dichloromethane and thionyl chloride were removed by rotary evaporation to obtain soybean oilyl chloride.

[0035] (3) Add 1.70g of sodium azide and 18.48g of deionized water into the reaction flask, put it in an ice bath, add the tetrahydrofuran solution dissolved in soybean oleyl chloride dropwise under s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com