Specific metal nanowire and production method thereof

A technology of metal nanowires and manufacturing methods, which is applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of needing holes, high production costs, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

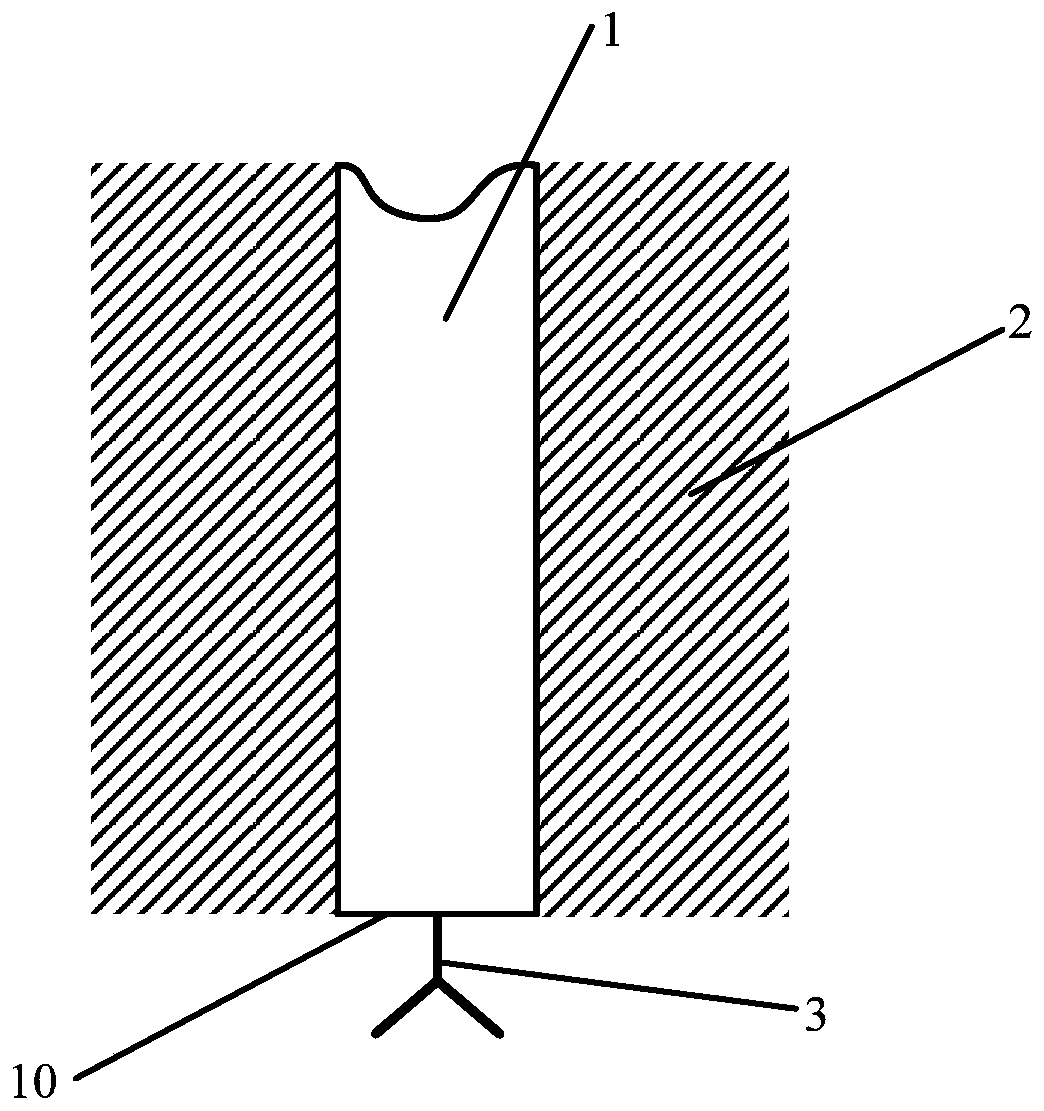

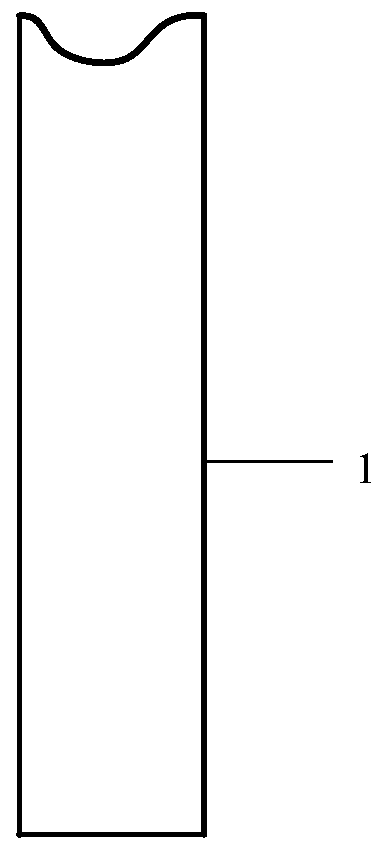

[0036] Such as figure 1 The schematic diagram of the overall structure of the specific metal nanowire shown, including: the nanowire substrate 1, the isolation layer 2 and the binding body 3 for coupling a single DNA molecule, the isolation layer 2 is coated on the nanowire by coating technology On the outer surface of the matrix 1, the top 10 of the nanowire matrix 1 is connected to a binding body 3, and in this embodiment, the binding body 3 is a single streptavidin.

[0037] The nanowire matrix 1 is prepared by a template method. The template method can be selected as any one of the porous alumina template method, the polymer film template method or the soft template method. The template method used in this embodiment is the porous alumina template method. The nanopores of the porous alumina template produce an array of nanowire substrates 1, satisfying that the diameter of the nanowire substrate 1 is the same as the pore diameter of the porous alumina template, so alumina ...

Embodiment 2

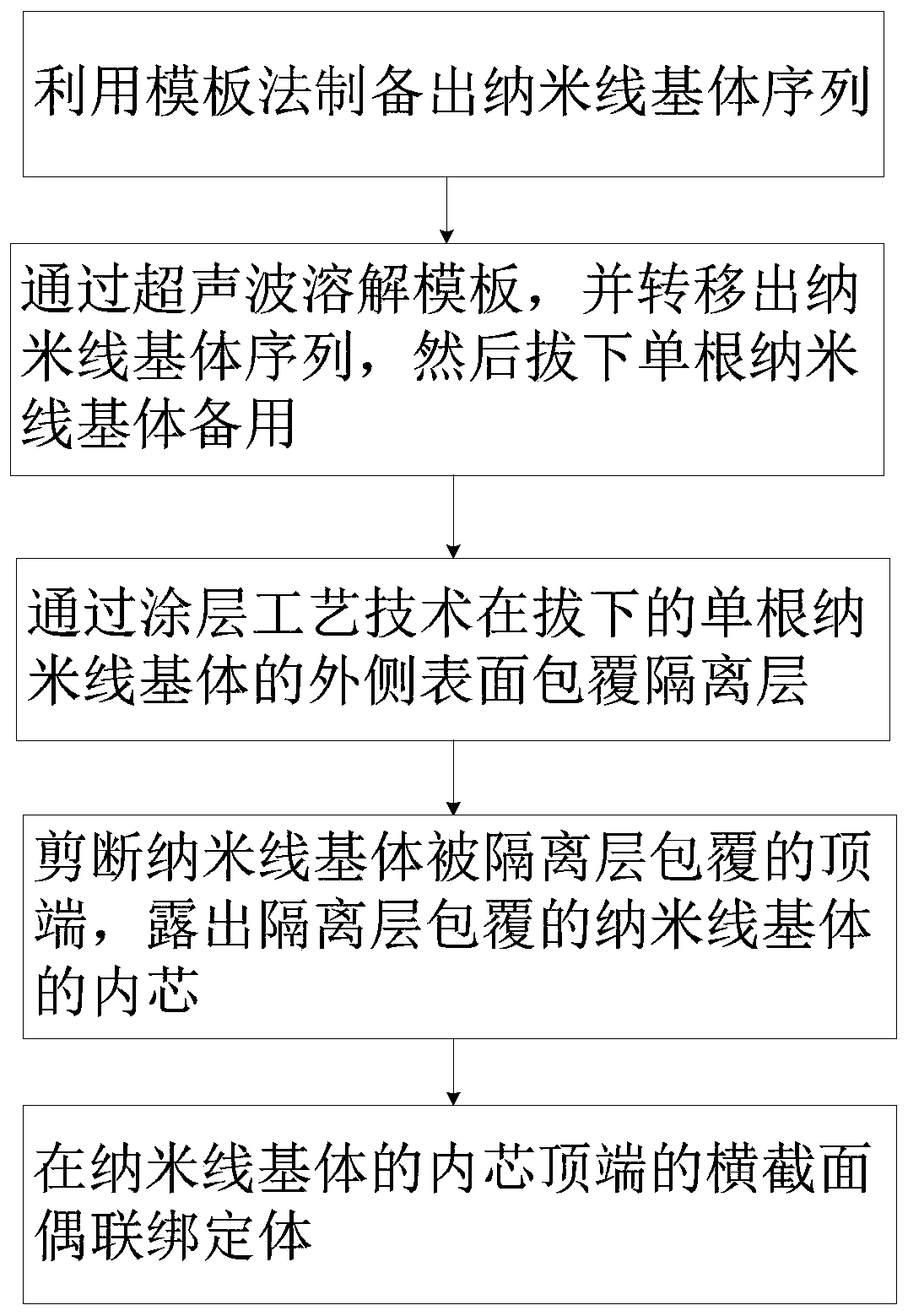

[0041]The present invention also proposes a method for making the above-mentioned specific metal nanowires, the flow chart of the method is as follows figure 2 shown, including the following steps:

[0042] Step 1: Use the template method to prepare the sequence of the nanowire matrix 1; in this embodiment, the template method used is the porous alumina template method, and the nanowire matrix 1 is made of silicon nanowires, and the nanowire substrate 1 is prepared by the porous alumina template method. The wires have a diameter of 50 nm and a length of 10 μm. The nanowire matrix 1 array produced by the nanopores of the porous alumina template satisfies that the diameter of the nanowire matrix 1 is the same as the pore diameter of the porous alumina template. Therefore, different alumina templates with different pore diameters can be prepared. An array of nanowire matrix 1 with a pore diameter, so that the diameter of the prepared nanowire matrix 1 can be controlled, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com