Resonant three-point-bending high-temperature fatigue testing machine

A fatigue testing machine and three-point bending technology, which are used in vibration testing, testing of machine/structural components, and testing of material strength using repetitive force/pulse force. It can solve the problems of difficult connection design and low test efficiency. To achieve the effect of compact and reasonable structure layout, low test cost and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

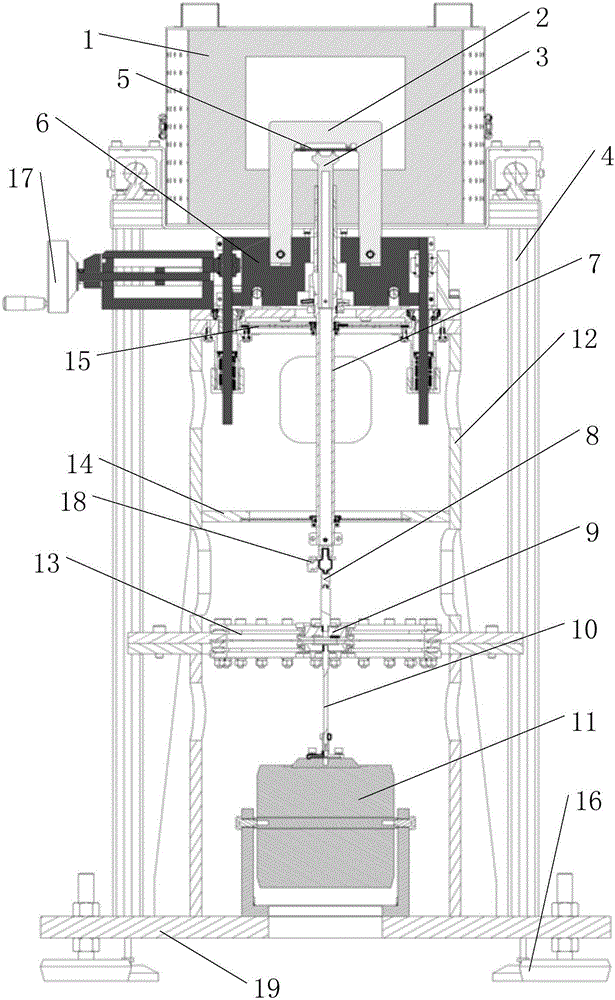

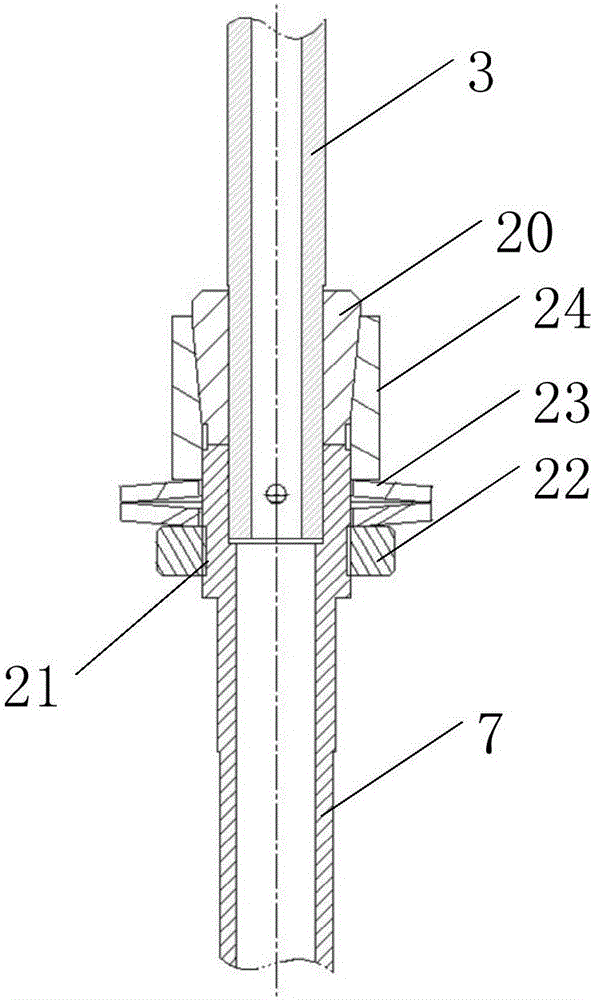

[0026] Such as figure 1 As shown, the present invention proposes a resonant three-point bending high-temperature fatigue testing machine, including a heating furnace 1, an upper fixture 2, a lower fixture 3, a heating furnace support 4, a static load adjustment device, an active rod 7, a dynamic sensor 8, a static Force sensor 9, excitation rod 10, vibrator 11, main frame 12, adjustable stiffness spring 13, lower motion positioning reed 14, upper motion positioning reed 15, acceleration sensor 18 and base 19.

[0027] The upper fixture 2 and the lower fixture 3 cooperate to clamp the test piece 5, and one end of the upper fixture 2 is fixed on the static load adjustment device, and the upper fixture 2 is adjusted to move up and down by adjusting the static load adjustment device, so as to realize static loading on the test piece.

[0028] The main frame 12 is a hollow cylinder with an upper cover, the static load adjustment device is placed on the upper cover of the main frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com