Feedback control system of water supply pump station with in-series same pumps

A technology of feedback control system and water supply pumping station, applied in the direction of control/regulation system, liquid level control, non-electric variable control, etc., can solve the waste of human resources, lack of automatic monitoring, and the lack of regionalized network for pumping station control and management and other issues to achieve the effect of improving management level and improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is specifically described below according to accompanying drawing:

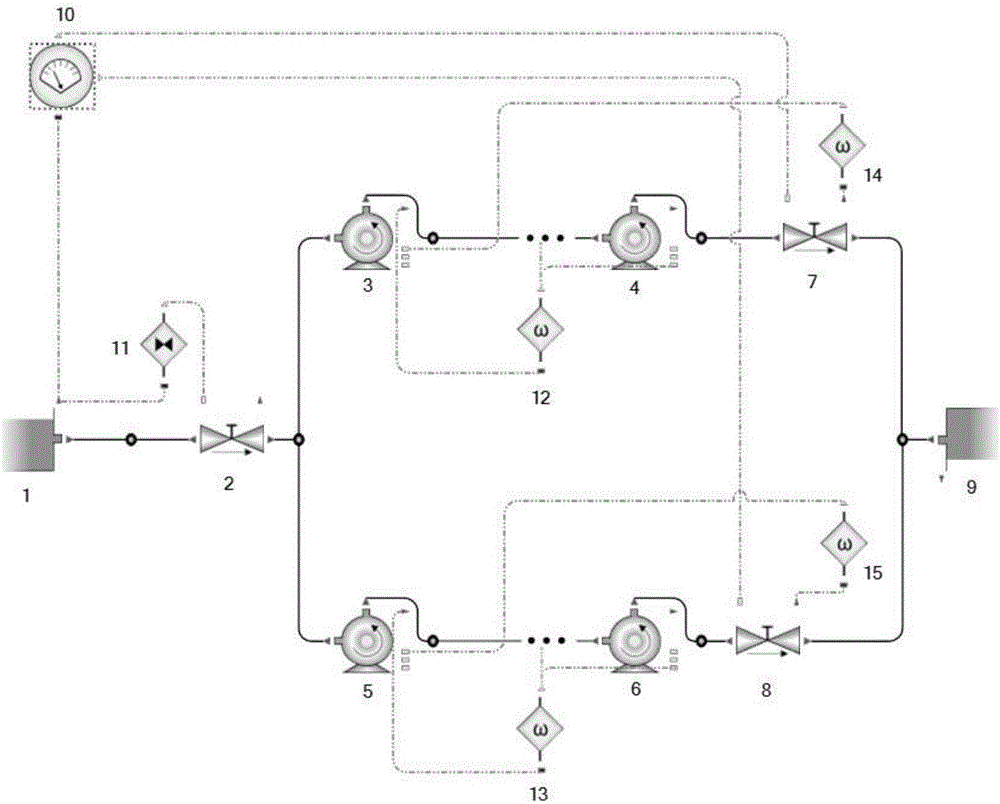

[0037] as attached figure 1The feedwater pumping station feedback system with the same pumps in series shown includes reservoir Ⅰ1, safety control valve 2, water supply working pump Ⅰ3, water supply working pump Ⅱ4, water supply working pump Ⅲ5, water supply working pump Ⅳ6, outlet adjustment Valve Ⅰ7, regulating valve Ⅱ8, next-level pumping station reservoir Ⅱ9, reservoir liquid level feedback control part 10 detects the liquid level water pressure near the outlet of reservoir Ⅰ1, and the feedback signal is sent to the regulating valve Ⅰ7 and regulating valve Ⅱ8 at the outlet , the safety control valve opening feedback control part 11 detects the liquid level water pressure near the outlet of the reservoir, the feedback signal is sent to the safety control valve 2, the pump-pump speed control part I12, the pump-pump speed control part II13, respectively detect the water supply pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com