Waste accumulated liquid drainage detecting device for process unit

A detection device and liquid accumulation technology, which is applied in the direction of electrical components, semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, etc., can solve the problem that chemical waste liquid cannot be discharged in time, so as to prevent splashing and leakage liquid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

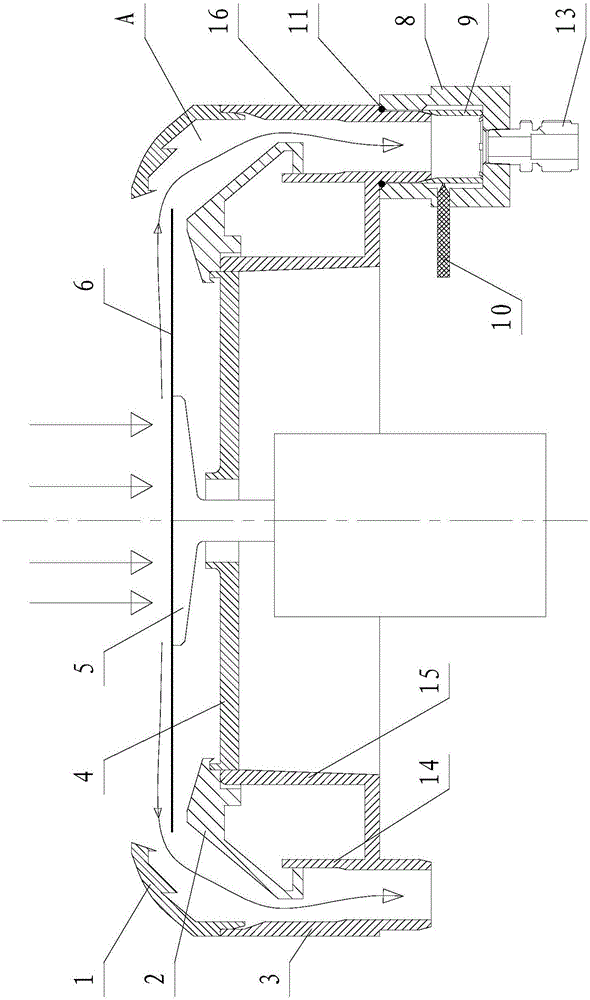

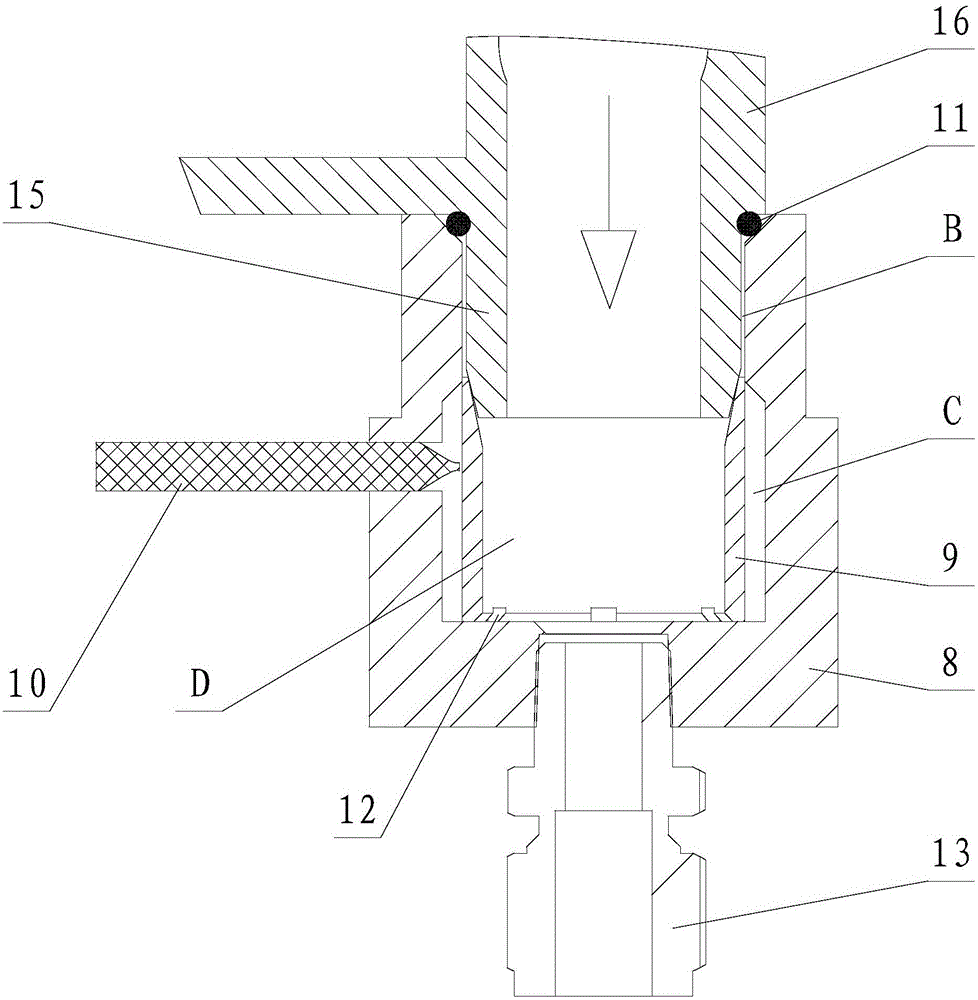

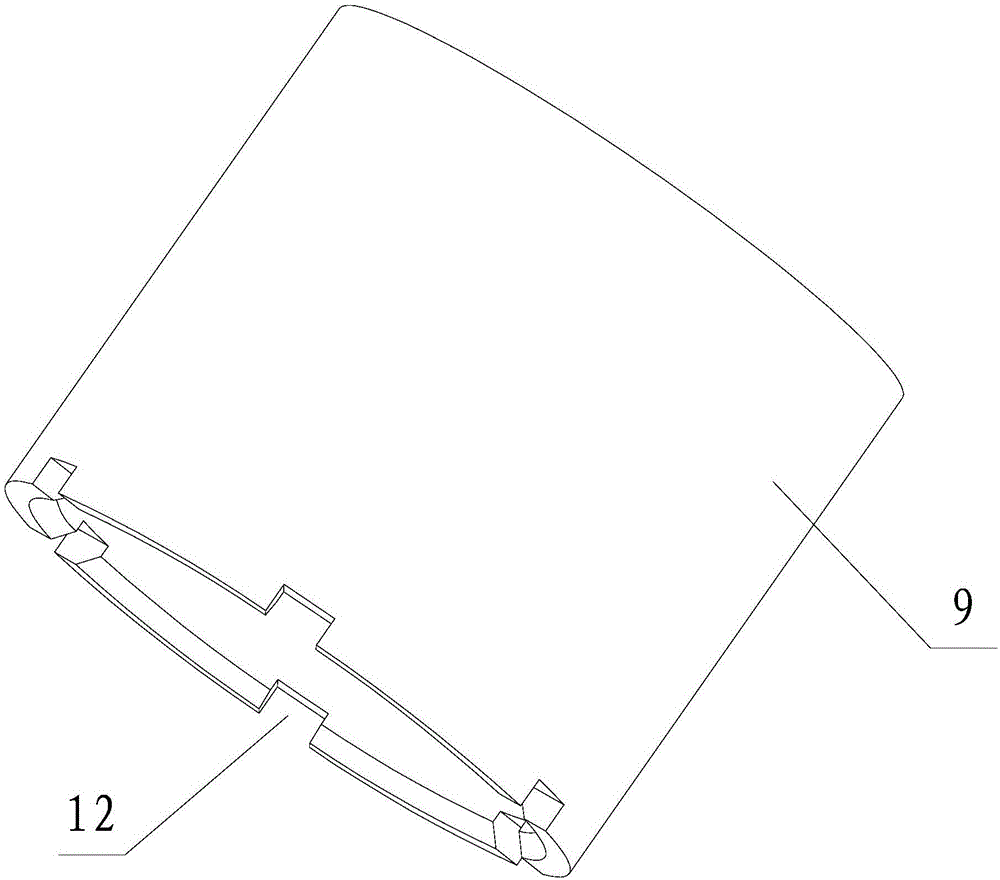

[0019] like figure 1 , figure 2 As shown, the present invention includes an upper cover 1, an inner cover 2, a lower cover 3, a first partition 4, a liquid accumulation box 8, an inner cover 9 and a liquid accumulation sensor 10, wherein the first partition 4 is installed in the working area of the process unit. On the platform, a motor 7 fixed on the workbench of the process unit is provided under the first partition 4. The output end of the motor 7 is connected to one end of the vacuum bracket 5 connected to the factory vacuum, and the other end of the vacuum bracket 5 One end passes through the first partition 4 to hold the wafer 6; the motor 7 provides a power source to drive the vacuum bracket 5 and the wafer 6 to rotate.

[0020] The lower cover 3 is installed on the workbench of the process unit and is located outside the first partition 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com