Waterproof USB connector and manufacturing method thereof

A connector and waterproof ring technology, applied in the connection of dust/splash/leakage/waterproof/fireproof, the manufacture and connection of contact box/base, etc. There are many joint cracks, glue variation and other problems, to improve the waterproof function and strengthen the sealing effect of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

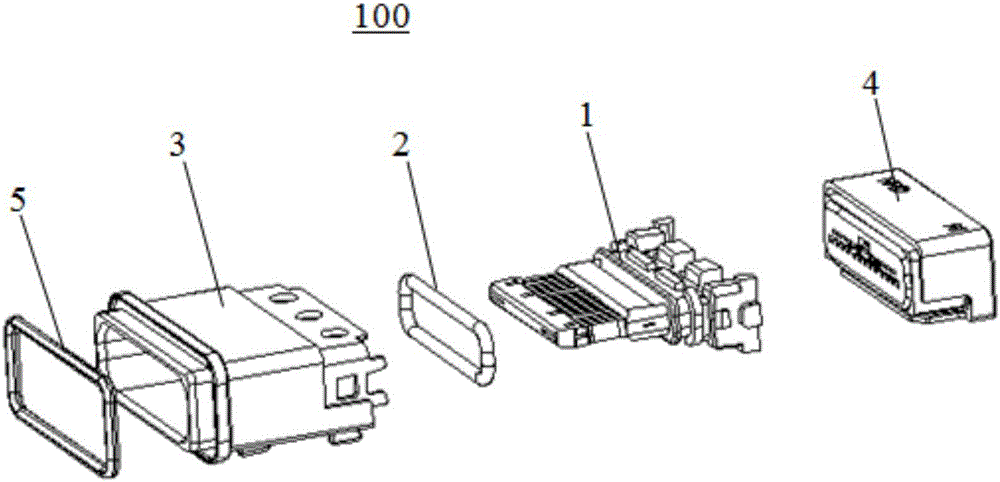

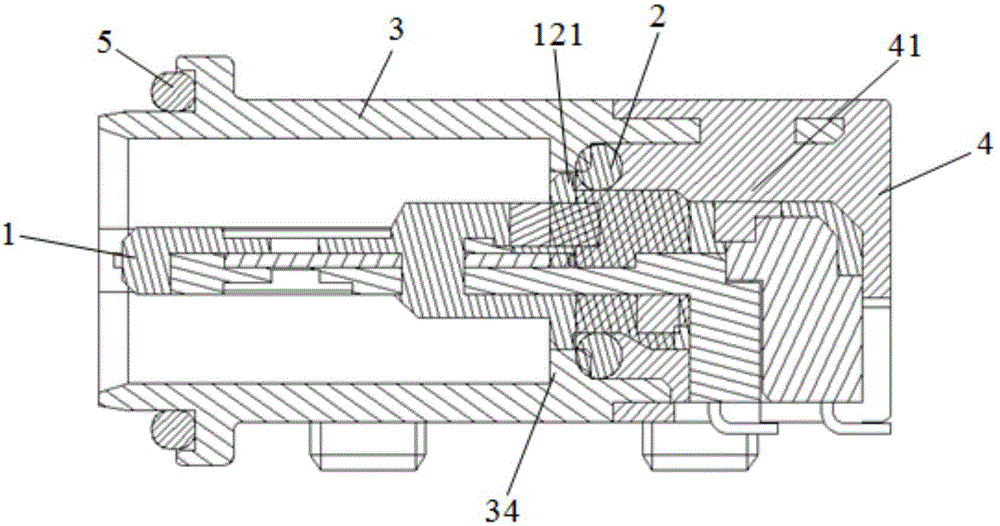

[0035] Please refer to Figure 1-Figure 5 , this embodiment is a waterproof USB connector, which includes a third terminal module 1, a first waterproof ring 2 sleeved on the third terminal module 1, wrapping the third terminal module 1 and the first waterproof ring 2 The first casing 3 that is housed, the second casing 4 that closes the rear end of the first casing 3 and is injection molded at the rear end of the first casing 3, and the second waterproof ring 5 sleeved on the front end of the first casing 3, The gap between the tail of the third terminal module 1 and the interior of the first housing 3 is completely filled by the second housing 4 .

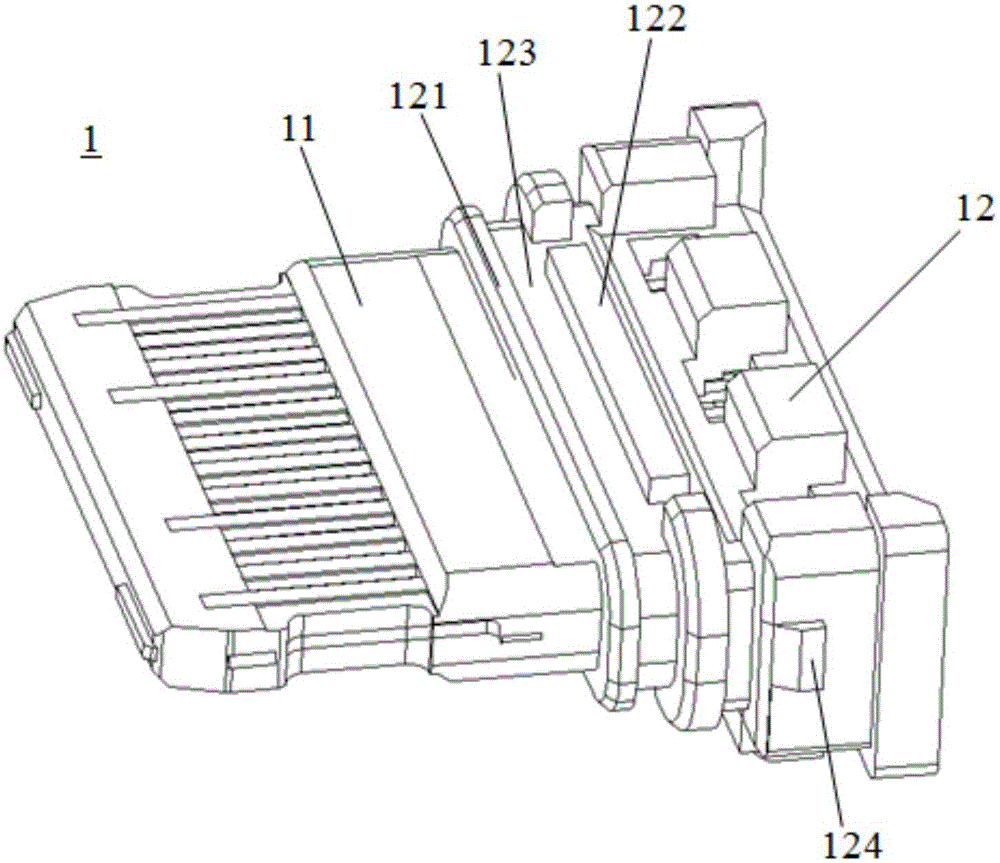

[0036] The third terminal module 1 includes a first terminal module, a second terminal module, and a plastic part integrating the first terminal module and the second terminal module. The third terminal module 1 includes a carrying portion 11 carrying metal terminal pins and a connecting portion 12 integrally injection-molded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com