Dry heat sterilization indicator and preparation method thereof

A dry heat sterilization and indicator technology, which is applied in heating, testing the degree of sterilization, sanitary equipment for toilets, etc., can solve the problems of affecting the interpretation of the results, deepening the color of the indicator, and difficult interpretation, etc., to achieve intuitive results and formula stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A dry heat sterilization indicator, its components and the mass parts of each component are:

[0017] 3 parts of methylaminoanthraquinone, 5 parts of polyvinylpyrrolidone, 90 parts of mannitol

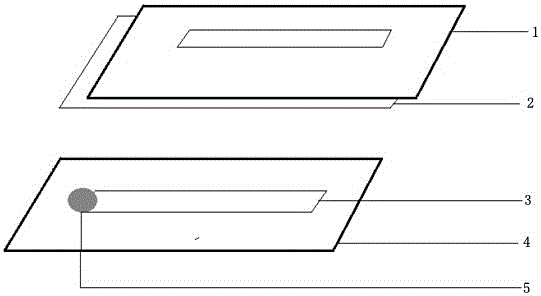

[0018] After the above components are uniformly stirred for 25-40 minutes, they are sent into a tablet machine for tablet compression. Finally, put the tablet into a device with an absorbent paper core and seal it to obtain a dry heat sterilization indicator.

Embodiment 2

[0020] A dry heat sterilization indicator, its components and the mass parts of each component are:

[0021] 1 part of methylaminoanthraquinone, 10 parts of polyvinylpyrrolidone, 90 parts of mannitol

[0022] After the above components are uniformly stirred for 25-40 minutes, they are sent into a tablet machine for tablet compression. Finally, put the tablet into a device with an absorbent paper core and seal it to obtain a dry heat sterilization indicator.

Embodiment 3

[0024] A dry heat sterilization indicator, its components and the mass parts of each component are:

[0025] 10 parts of methylaminoanthraquinone, 10 parts of polyvinylpyrrolidone, 50 parts of mannitol

[0026] After the above components are uniformly stirred for 25-40 minutes, they are sent into a tablet machine for tablet compression. Finally, put the tablet into a device with an absorbent paper core and seal it to obtain a dry heat sterilization indicator.

[0027] During monitoring, put the above-mentioned dry heat sterilization indicators, biological indicators and articles to be sterilized together in packaging materials, and use a closed method for packaging. After packaging, put it in a dry heat sterilizer for sterilization. The sterilization temperature is 160°C, and the sterilization time is 2 hours. After the sterilization is finished, take out the above-mentioned package, the sterilization indicator covers the entire absorbent paper core, and the biological indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com