Stator machining method and device and rotor machining method and device

A processing equipment and processing method technology, applied in the direction of metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of complex processing technology, difficult processing, high cost, etc., and achieve wide application range, short processing cycle and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]This embodiment is a stator processing method. Using the principle of relative motion between the stator and the rotor, the rotor is made into a stator tool, and the inner cavity of the stator is cut through the stator tool. The driving device of the stator tool is an autorotation and revolution drive with a feeding function. The device makes the stator tool not only rotate around the axis of the stator tool itself, but also perform revolution around the axis of the stator during the feed movement.

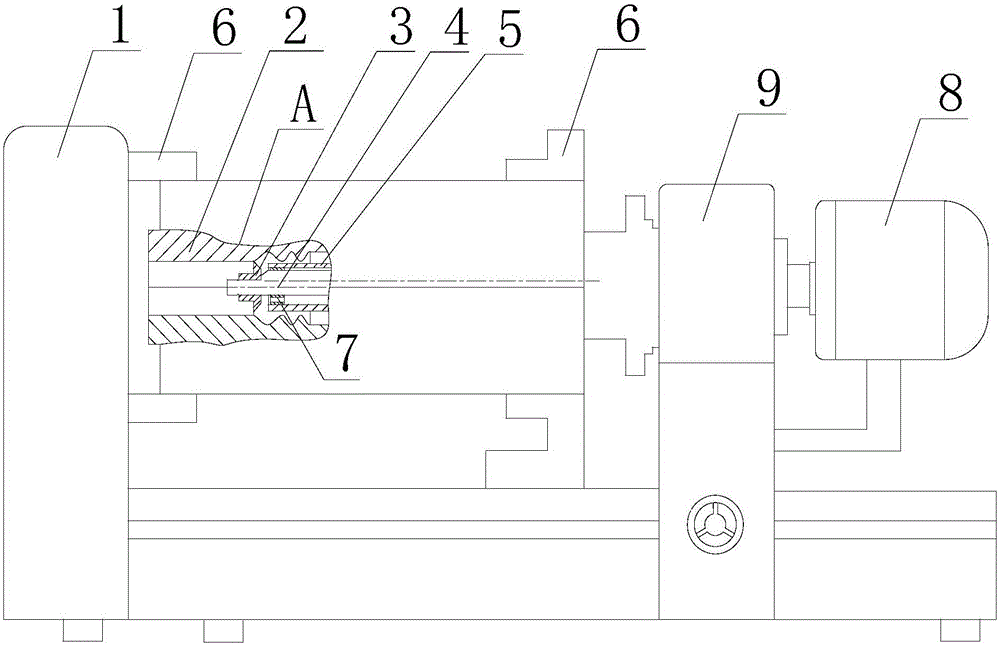

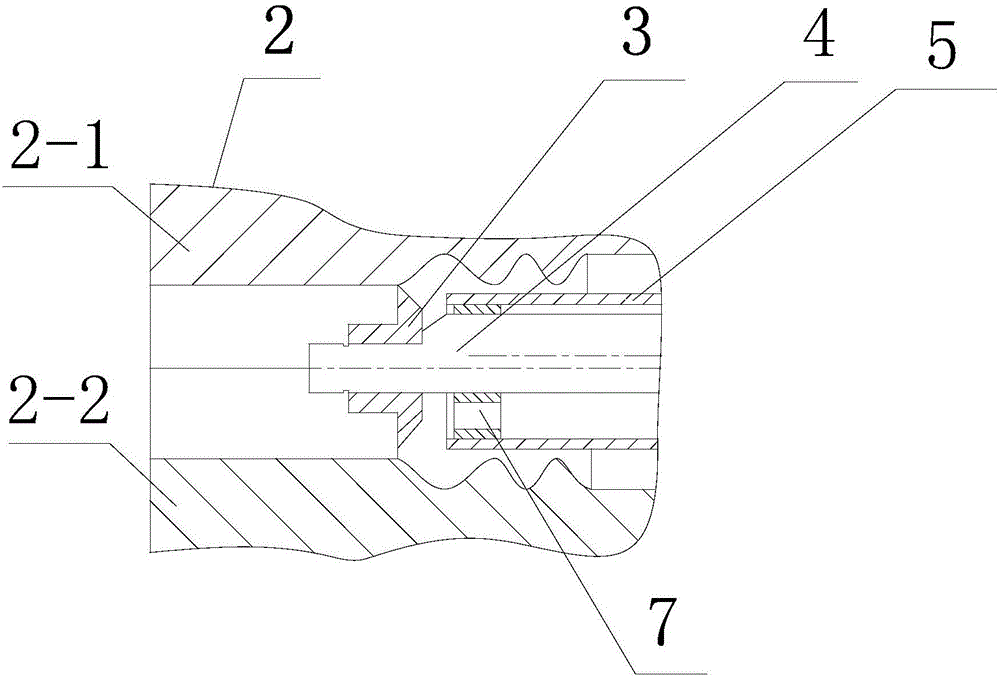

[0033] A stator processing equipment for realizing the above method, such as figure 1 As shown, it includes machine tool 1, rotation and revolution drive device, stator 2, stator cutter 3, stator cutter drive rod 4 and stator cutter support sleeve 5, the rotation and revolution drive device is arranged on the machine tool, and the two ends of the stator pass through the chuck 6 and the machine tool respectively. connection, the stator cutter is set in the inner cavity of the...

Embodiment 2

[0038] This embodiment is a rotor processing method, using the principle of relative motion between the stator and the rotor, the stator is made into a rotor tool, and the outer periphery of the rotor is cut through the rotor tool, and the driving device of the rotor is an autorotation and revolution driving device with a feeding function. In the process of feeding the rotor, the rotor not only rotates around the axis of the rotor itself, but also revolves around the axis of the rotor cutter.

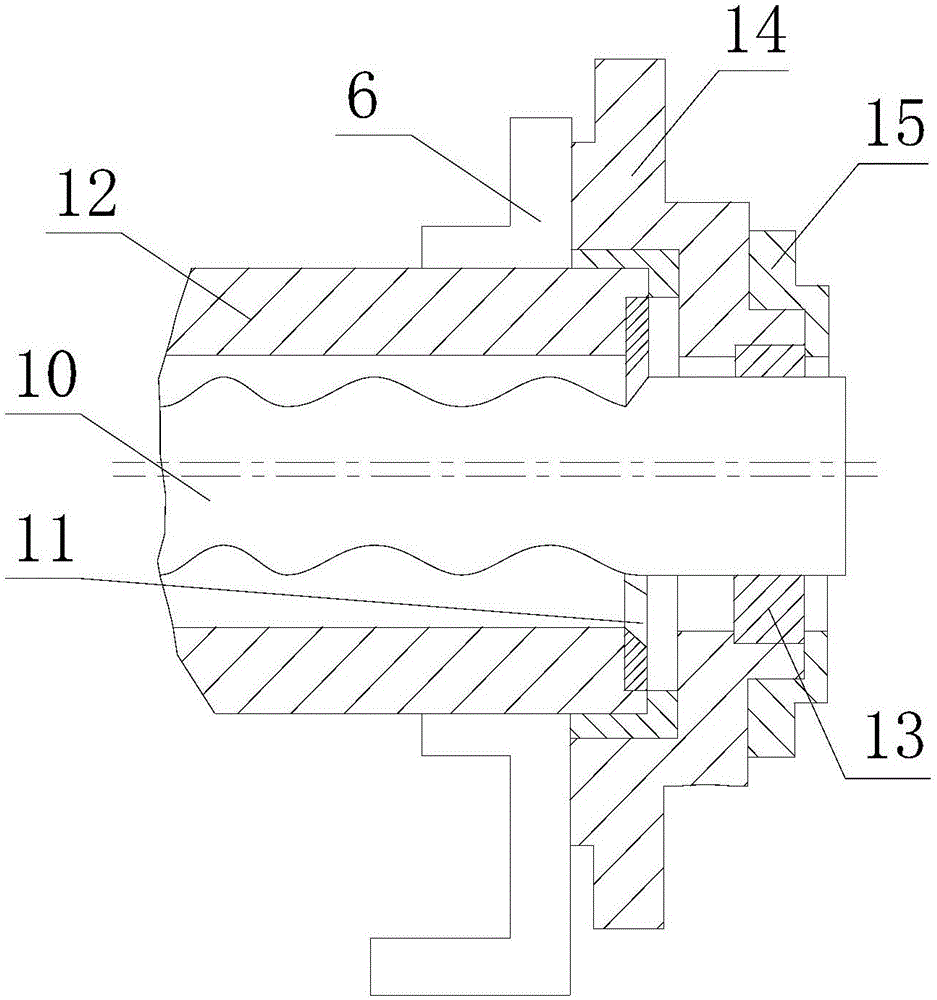

[0039] A rotor processing equipment for realizing the above method, such as image 3 As shown, it includes a machine tool, an autorotation and revolution driving device, a rotor 10, a rotor tool 11 and a rotor tool driving sleeve 12. The autorotation and revolution driving device is arranged on the machine tool, and the two ends of the rotor tool driving sleeve are respectively connected to the machine tool through chucks 6. The rotor tool A rotor cutter is installed on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com