Continuous aluminum foil pressure forming composite winding machine

A compression molding and winding machine technology, applied in lamination, lamination devices, layered products, etc., can solve problems such as low production efficiency, misalignment, and difficulty in ensuring product quality, and achieve precise composite processing and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

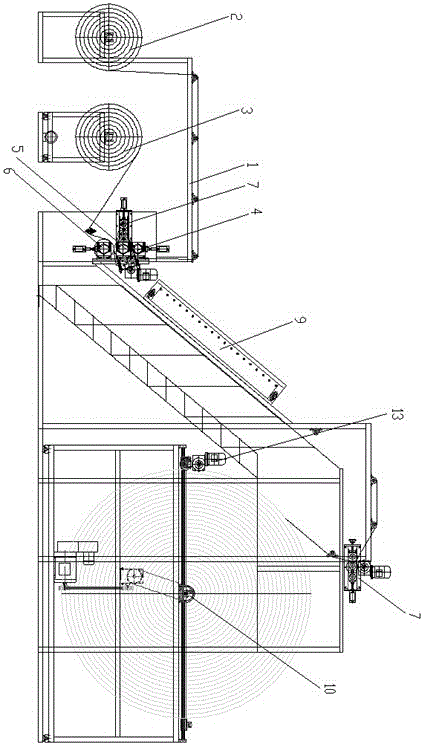

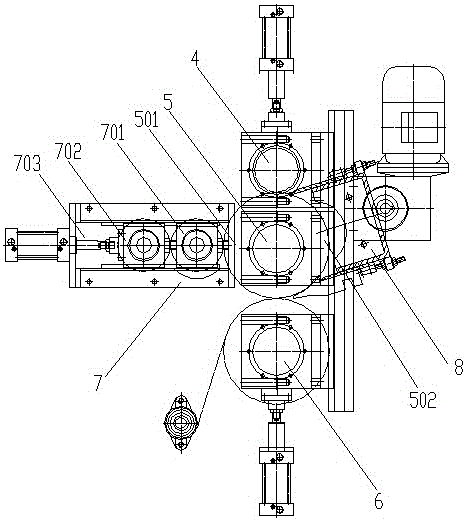

[0025] Such as figure 1 and figure 2 A compound winding machine for aluminum foil continuous compression molding is shown, which includes a frame 1, on which a first unwinding device 2, a second unwinding device 3, a compression molding composite mechanism and a winding device are sequentially arranged on the frame 1 device; the compression molding composite mechanism includes a first corrugated roller 4, a second corrugated roller 5 and a pressure roller 6, wherein the first corrugated roller 4 and the second corrugated roller 5 are attached to each other, and the second corrugated roller 5 Attached to the pressure roller 6, the second corrugated roller 5 includes a first end surface 501 extending at the aluminum foil conveying position, and a second end surface 502 extending away from the aluminum foil conveying position, and the second corrugated roller 5 is respectively A gluing device 7 and a vacuum adsorption device 8 are provided, wherein the gluing device 7 is arrang...

Embodiment 2

[0035] As an improvement of the present invention, in the compression molding composite mechanism, a synchronous gear is arranged on the roller shafts of the second corrugated roller 5, the pressure roller 6, the top rubber roller 701, and the extrusion roller 702, and the second corrugated roller 5 and the synchronous gear on the roller shaft of the pressure roller 6 are meshed with each other, the synchronous gears on the roller shaft of the upper rubber roller 701 and the squeeze roller 702 are meshed with each other, and the second corrugated roller 5 and the roller shaft of the upper rubber roller 701 are in mesh with each other. The synchronous gears on the gear mesh with each other. Adopting the above-mentioned technical scheme, it can realize the synchronous operation of the second corrugated roller, pressure roller, top rubber roller and extruding rubber roller through the setting of synchronous gears among different components, so that the first corrugated roller and ...

Embodiment 3

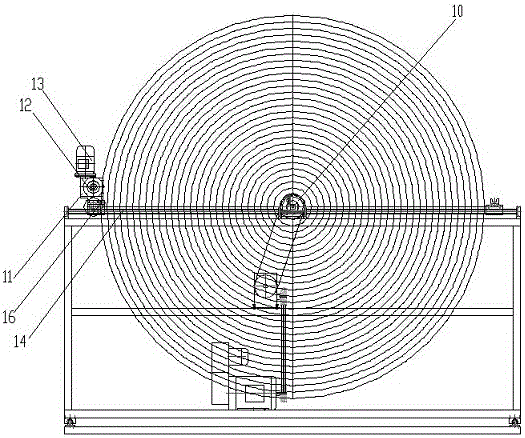

[0038] As an improvement of the present invention, such as Figure 4 As shown, the driving motor 13 and the auxiliary winding roller 12 are respectively provided with a driving gear 15 meshing with each other, and the driving motor 13 drives the auxiliary winding roller 12 to rotate through the driving gear 15 .

[0039] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com